Connector

A technology for connectors and mating connectors, which is applied in the direction of connection, two-part connection devices, parts of connection devices, etc., to achieve the effects of improving assembly and pulling out operability, improving pulling out operability, and realizing miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

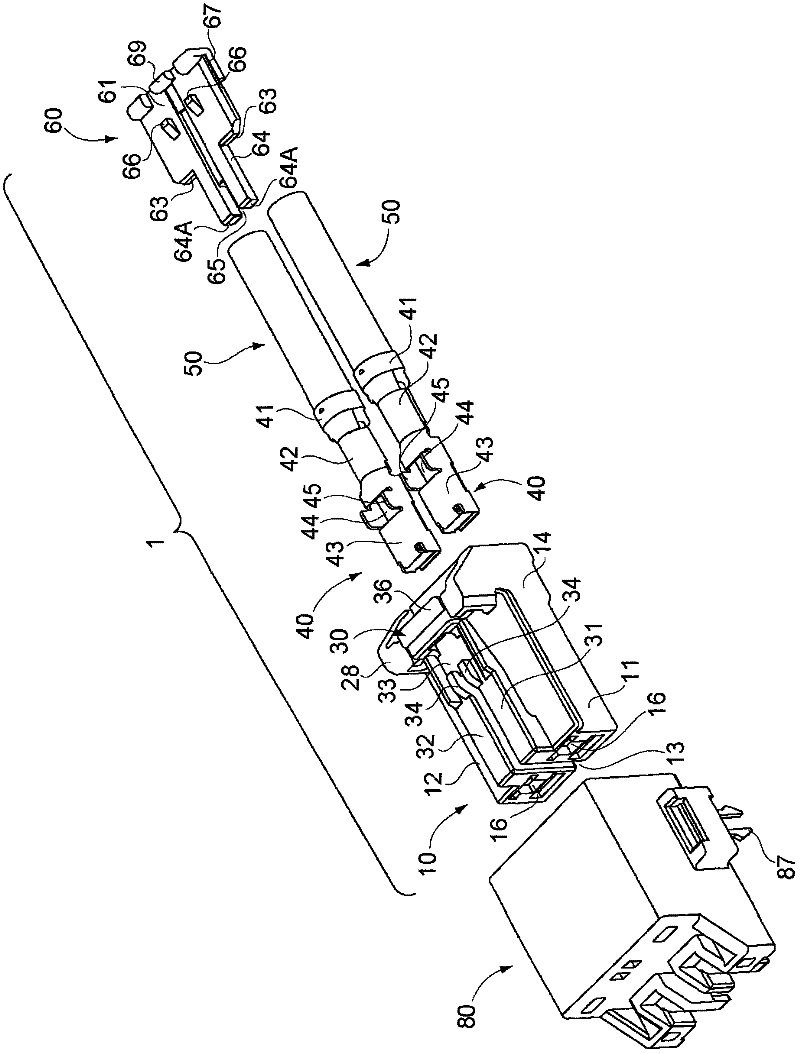

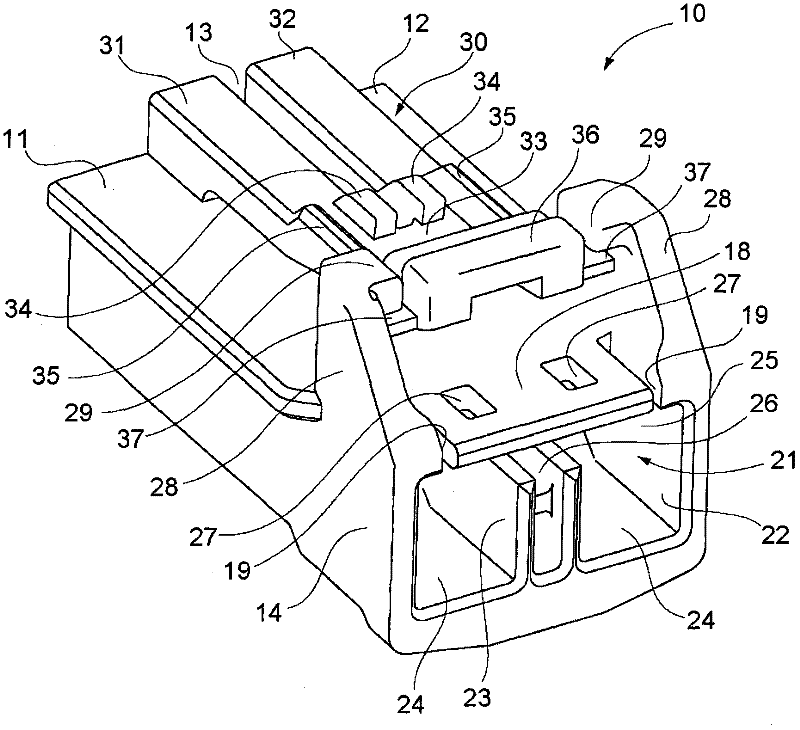

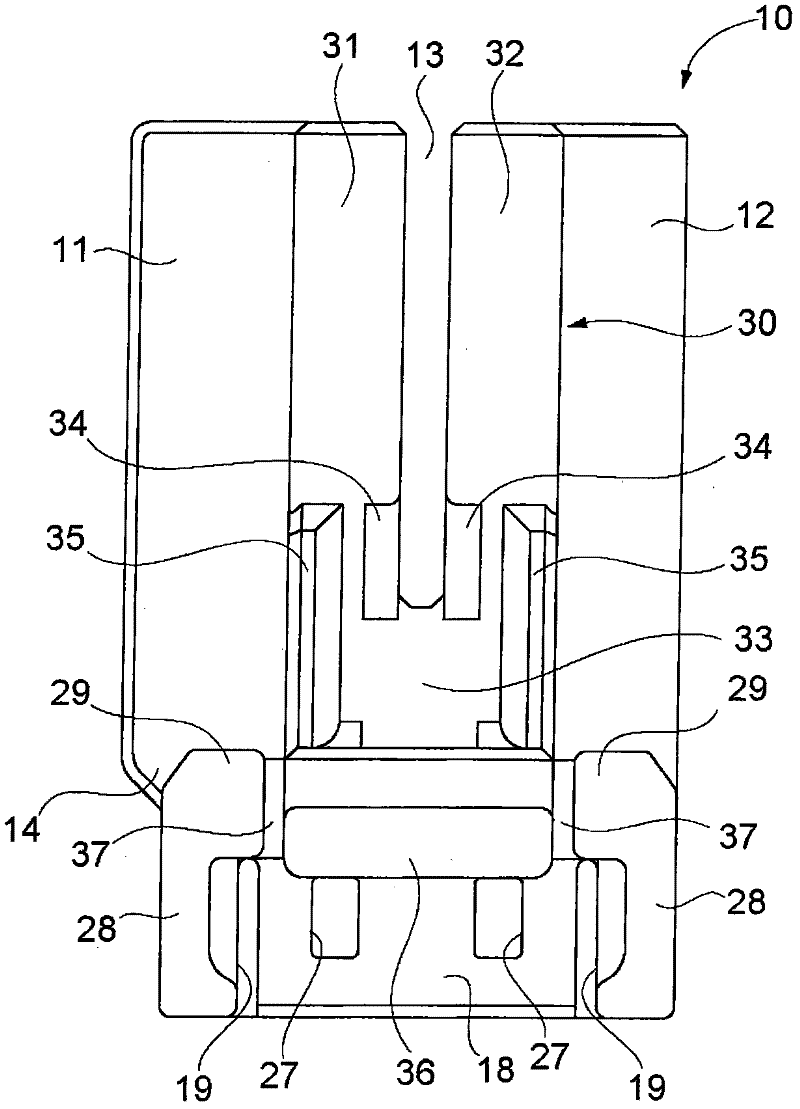

[0046] figure 1 A connector and a mating connector according to the first embodiment of the present invention are shown. Such as figure 1 As shown, the connector 1 according to the first embodiment of the present invention includes a housing 10, two connection terminals 40 mounted on the end of a cable 50 and accommodated in the housing 10, and holding each connection terminal 40 and each cable. Holder 60 for wire 50 . The front end side of the case 10 is separated, thereby securing a long creeping distance between the connection terminals 40 and improving the pressure resistance between the connection terminals 40 . Furthermore, the connector 1 has a locking mechanism 30 that engages with the mating connector 80 . When the connector 1 is inserted into the mating connector 80 , the locking mechanism 30 engages with the mating connector 80 , and the connector 1 and the mating connector 80 are locked to each other so that they are not easy to disengage.

[0047] Connector 1 ...

no. 2 Embodiment approach

[0071] Figure 10 It is a plan view showing the housing of the connector according to the second embodiment of the present invention. Such as Figure 10 As shown, based on the connector 100 of the second embodiment of the present invention, the front end side of the housing 110 is divided into three separate parts 111, 112, 113, and between the separate part 111 and the separate part 112, the separate part 112 and the separate part There are gaps 114 between the portions 113, respectively. Furthermore, a coupling portion 115 where the separation portions 111 , 112 , 113 are coupled is formed on the base end side of the housing 110 . In each separation part 111, 112, 113, like the above-mentioned connector 1 according to the first embodiment of the present invention, a terminal accommodating part opening to the front end side of the housing 110 is formed, and each terminal accommodating part accommodates and connects terminals. In addition, a cable insertion portion opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com