High-voltage combined electrical apparatus

A combined electric appliance and high-voltage technology, which is applied in the high-pressure field, can solve the problems of high pressure, difficulty in breaking the induced current, and slow breaking speed of the grounding interface, so as to meet the requirements of reducing manufacturing difficulty, realize closing and closing short-circuit current, and ensure The effect of insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Specific embodiments of the present invention are provided below in conjunction with the accompanying drawings.

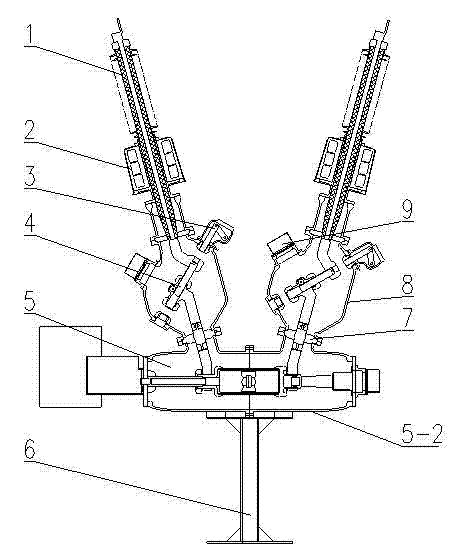

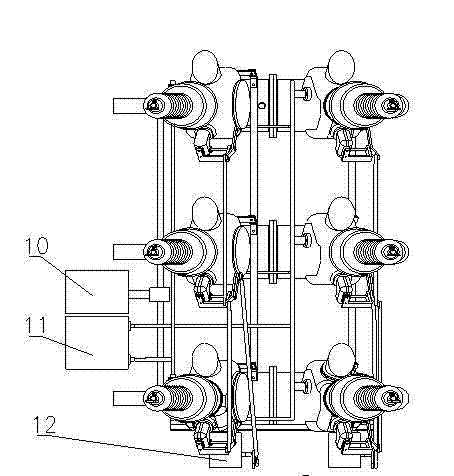

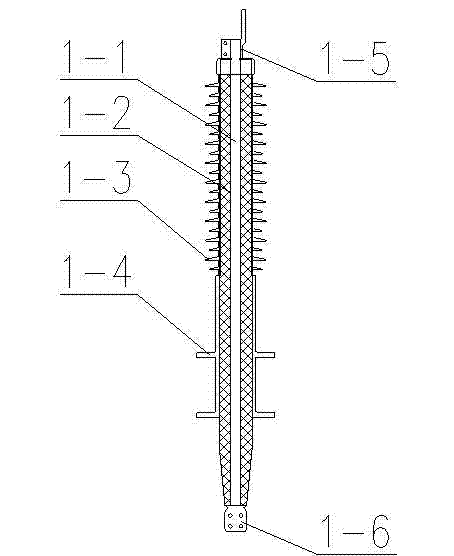

[0067] Such as figure 1 and figure 2 As shown, the technical solution adopted in the present invention includes a high-voltage vacuum circuit breaker 5, a three-position switch, a quick grounding switch 3 and a solid insulating bushing 1. The high-voltage vacuum circuit breaker 5 is a three-phase independent structure, and each phase is The recumbent tank structure is installed on the bracket 6 through the tank body 5-2. The left side of the high-voltage vacuum circuit breaker 5 is connected to the circuit breaker operating mechanism 10 through a linkage mechanism, and each phase of the high-voltage vacuum circuit breaker 5 is connected to a For the disc bushing 7, the high-voltage vacuum circuit breaker 5 and the isolating switch tank 8 are divided into two air chambers, the top of each disc-shaped bushing 7 is connected to the isolating switch tank 8, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com