Transmission device for sand cylinder polishing machine

A transmission device and polishing machine technology, applied in the direction of grinding drive device, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of inconvenient installation, complex structure, high cost, etc., and achieve safe and reliable work, The effect of low empty consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

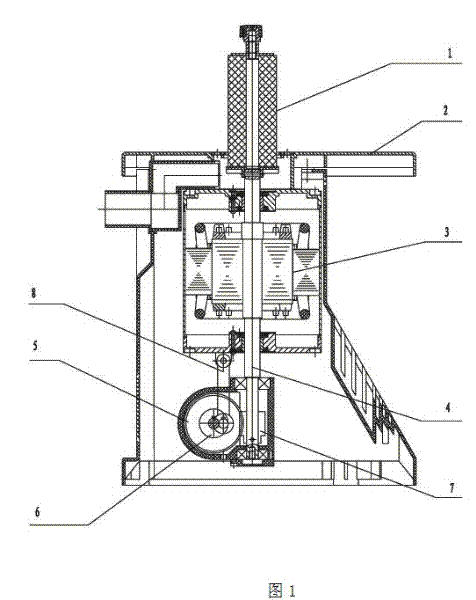

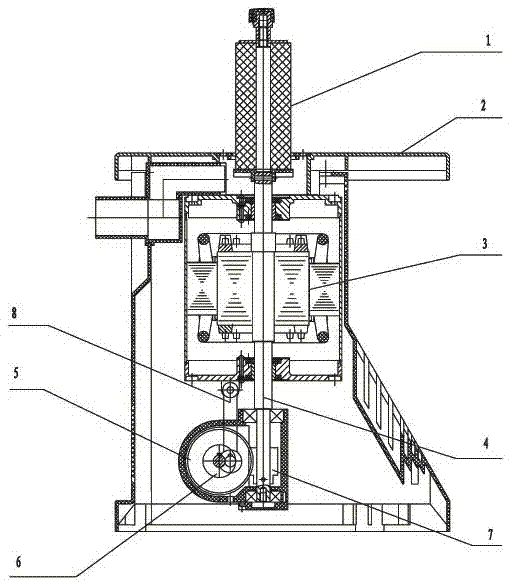

[0008] Depend on figure 1 As shown in the figure, a transmission device of a sand barrel grinder, the motor 3 is provided with upper and lower shaft extensions, the upper end cover of the motor is under the workbench 2, the sand barrel 1 is installed on the upper end shaft extension, and the workpiece is placed on the workbench For grinding and polishing, a worm 5 is provided on the shaft extension of the lower end of the motor, and the worm 5 is connected with the turbine 7, and a connecting rod 8 is provided on the lower end cover of the motor, and the lower end of the connecting rod is connected with the eccentric wheel 6 provided on the turbine, and the motor The main shaft 4 rotates, and the eccentric wheel on the worm wheel is driven to rotate through the connection between the worm and the worm gear, so that the connecting rod on the eccentric wheel reciprocates up and down, drives the motor shaft to reciprocate up and down, and realizes the axial rotation and up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com