On-line measuring method and apparatus for degree of crystallization of polymer used for injection molding

A measurement method and polymer technology, applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve the problems of poor versatility, expensive equipment, cumbersome use, etc., and achieve the effect of wide application range, simple structure, and fast feedback speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the present embodiment, the polymer material selects polyethylene (PE), and the parameters of the injection molding process are as follows:

[0043] Process parameters

value

Process parameters

value

Injection temperature (℃)

220

Holding pressure (MPa)

45

Mold temperature (℃)

40

Holding time (s)

20

Injection time (s)

1

Cooling time (s)

20

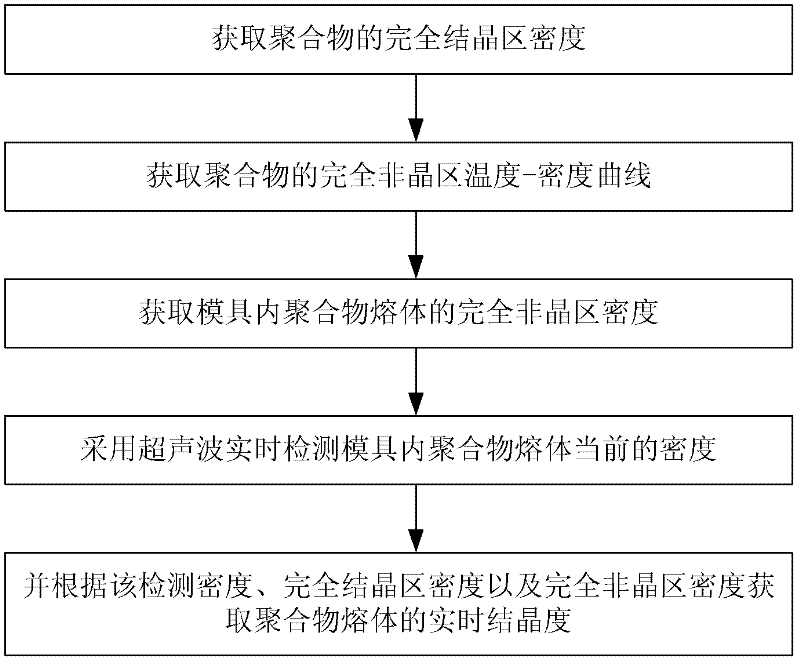

[0044] like figure 1 As shown, the implementation steps of the polymer crystallinity online measurement method used in the injection molding process in this embodiment are as follows:

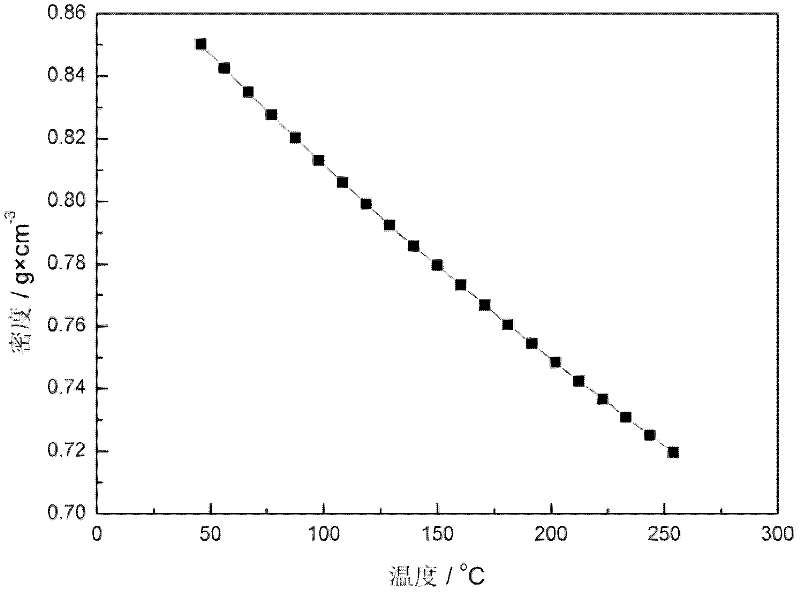

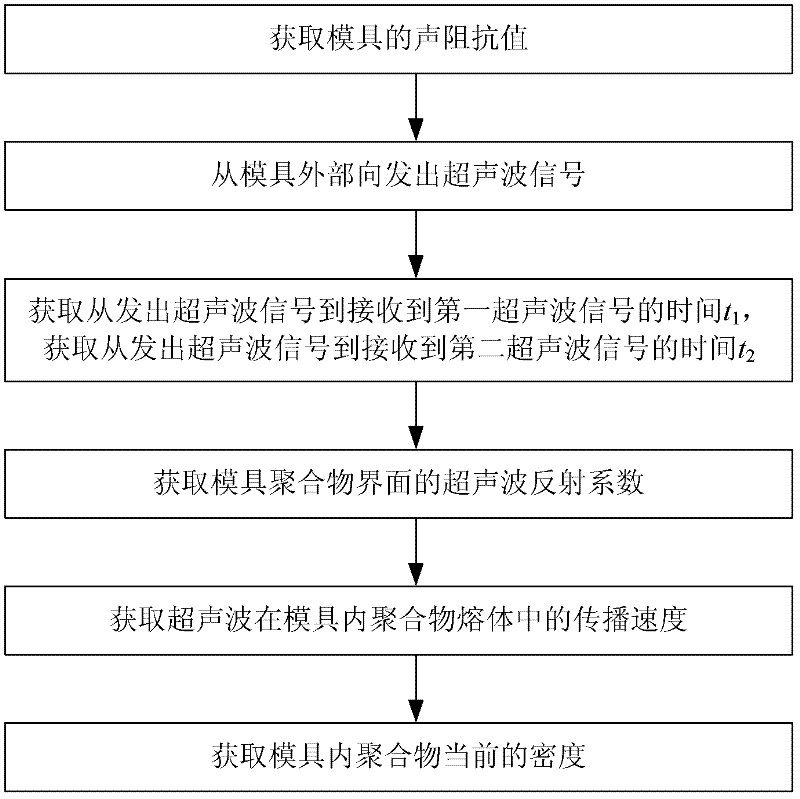

[0045] 1) Obtain the fully crystalline region density ρ of the polymer c , to obtain the temperature-density curve of the completely amorphous region of the polymer;

[0046] 2) Real-time detection of the current melt temperature T of the polymer melt in the mold a ,according to

[0047] ρ a = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com