Side wall supporting structure and hopper car

A technology of support structure and hopper car, which is applied in the direction of hopper car, transport passenger car, railway car body parts, etc. It can improve the connection reliability, improve the volume utilization rate, and increase the overall rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

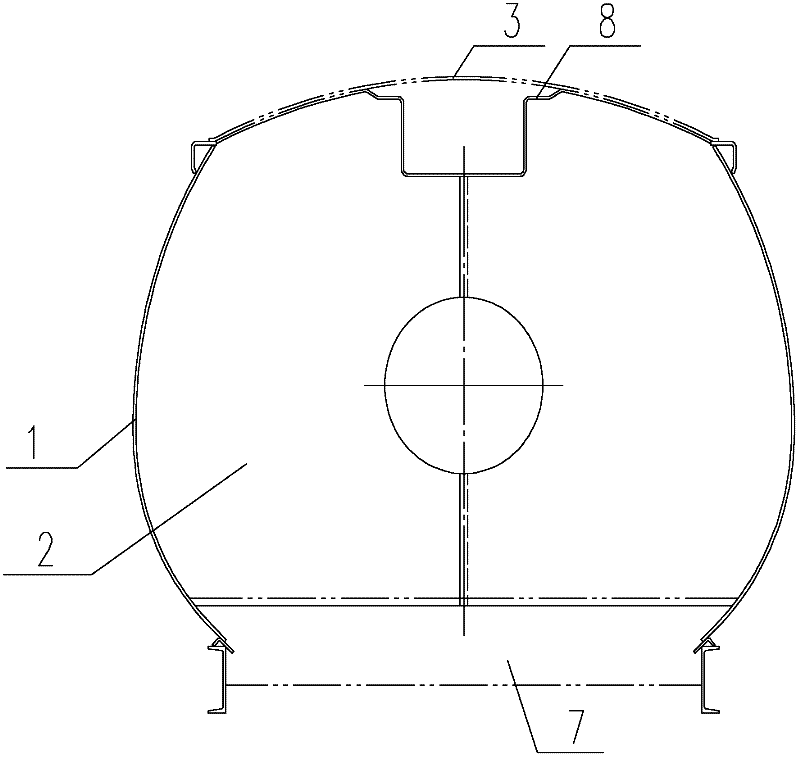

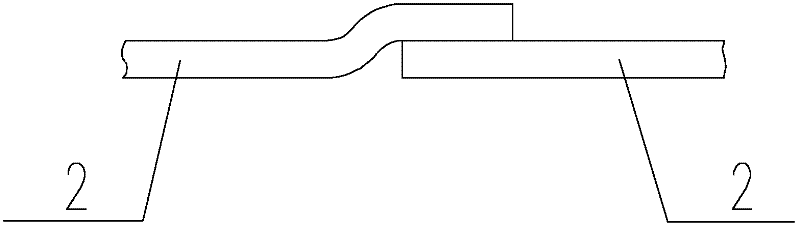

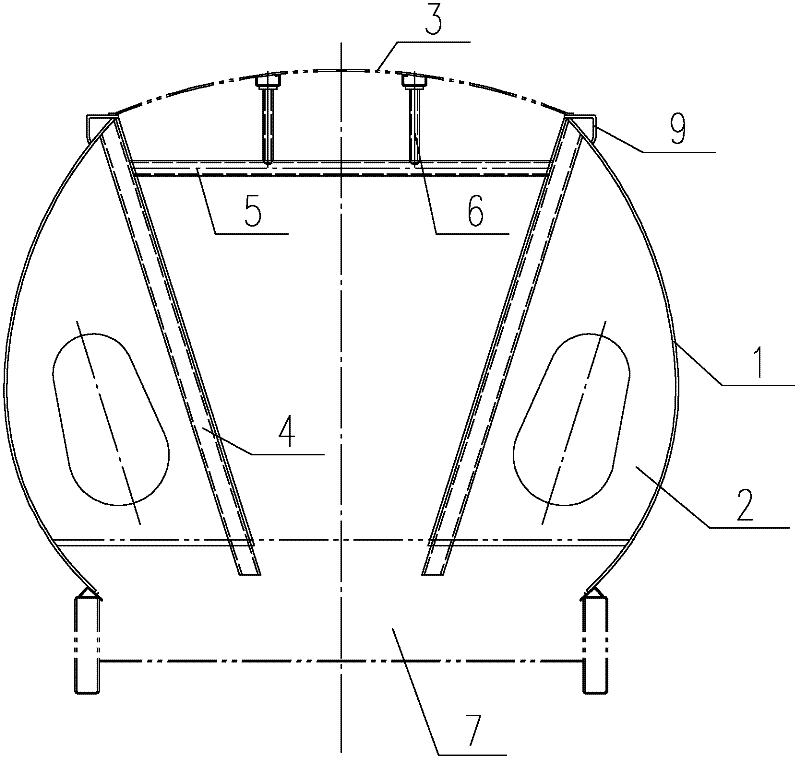

[0024] image 3 It is a schematic cross-sectional view of a hopper car adopting the side wall support structure of the present invention; Figure 4 It is a top view of the side wall support structure of the present invention.

[0025] The side wall support structure provided by this embodiment is as image 3 As shown, it includes a connecting beam 5 and two supporting units. The supporting unit includes a side wall support plate 2 and a reinforcing beam 4 fixed on one side of the side wall support plate 2. The side wall support plate 2 is semicircular in shape, and a There are through holes to facilitate the flow of bulk goods in the hopper car. The edge of the side wall support plate 2 away from the reinforcement beam 4 is a circular arc matching the inner edge of the side wall plate 1, and is welded and fixed in the side wall plate 1, and the side wall support plate 2 plays the role of supporting the side wall plate 1 ; The side wall support plate 2 is welded and fixed on...

Embodiment 2

[0030] This embodiment provides a hopper car, including side wall boards and multiple side wall support structures in Embodiment 1. The multiple side wall support structures are arranged in parallel along the length direction of the hopper car, and the side wall support plates of the side wall support structures are connected to the funnel The inner side of the side wall panel of the car is matched and fixed on the inner side of the side wall panel, and the reinforcing beam is fixed on the back of the funnel car. The plane where the side wall support plate is located is perpendicular to the axis of the hopper car.

[0031] When the side wall support structure is provided with a support beam, the installation of the side wall support structure in the vehicle should enable the support beam to support the roof panel at the same time.

[0032] The hopper car provided in Example 2 has light weight, and there is no problem of repose angle when filling bulk goods, which greatly impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com