System for removing formic acid generated during dimethylformamide recovering process

A technology of dimethylformamide and formic acid, which is applied in the field of formic acid system, can solve the problems of DMF that affects the recovery, the content of formic acid exceeds the standard, and formic acid cannot be completely decomposed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

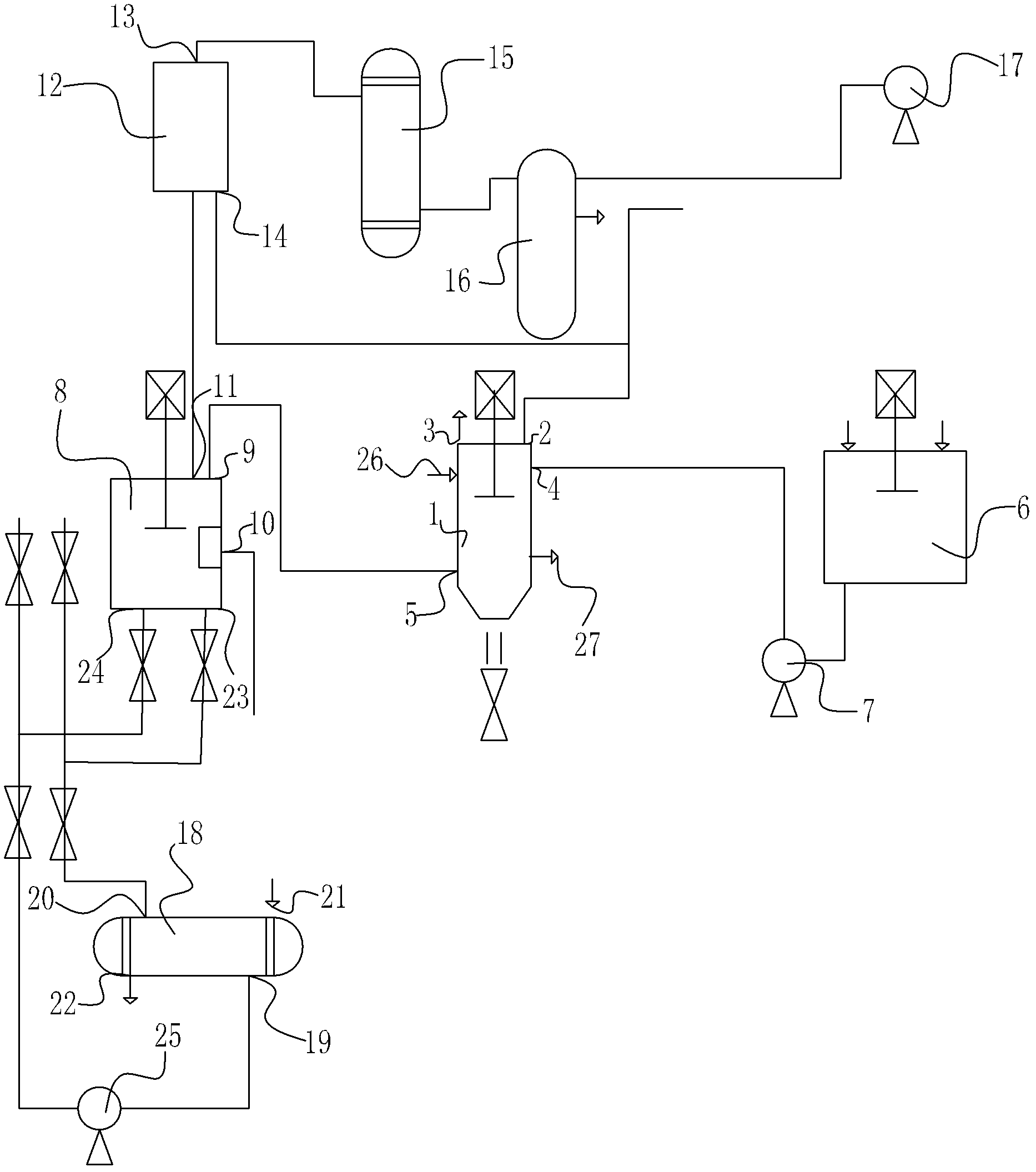

[0012] The present invention will be further described below in conjunction with specific drawings.

[0013] As shown in the figure: the system for removing formic acid produced in the recovery process of dimethylformamide includes recovery pot 1, DMF concentrated liquid inlet 2, first gas outlet 3, lye inlet 4, liquid waste residue outlet 5, alkali distribution tank 6 , alkali pump 7, dryer 8, liquid waste residue inlet 9, dry residue outlet 10, water vapor outlet 11, water vapor separator 12, second gas outlet 13, liquid outlet 14, residue condenser 15, condensate tank 16, vacuum pump 17. Heat transfer oil cooler 18, first heat transfer oil inlet 19, first heat transfer oil outlet 20, cooling water inlet 21, cooling water outlet 22, third heat transfer oil inlet 23, third heat transfer oil outlet 24, heat transfer oil cooling pump 25. The second heat transfer oil inlet 26, the second heat transfer oil outlet 27, etc.

[0014] The present invention comprises recovery boiler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com