A hot-air-assisted microwave spray drying method for shellfish

A technology of microwave spouting and drying method, which is applied in the fields of drying and preserving meat/fish, heating and preserving meat/fish, food science, etc. Good tissue structure and chewability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The specific steps of drying and processing shellfish into snack food are as follows:

[0021] (1) Pretreatment: wash the shellfish.

[0022] (2) Blanching: The purpose is to passivate the enzymes that cause oxidative browning of shellfish meat, and at the same time, it is convenient to reduce the microbial content. Moderate blanching temperature and time can not only inactivate enzyme activity and reduce microbial content; while excessive blanching heats shellfish meat protein to shrink and harden. The specific method is to use 90 ~ 100 ℃ water blanching for 1min, shellfish shell just opened, cool, take the meat, and drain and control the water.

[0023] (3) Coating film: In order to prevent the material from colliding with the wall of the drying box during spraying and causing breakage and loss, a protective film is coated on the shellfish meat surface to prevent breakage. At the same time, in order to improve the taste of snack food, seasoning is added to the prote...

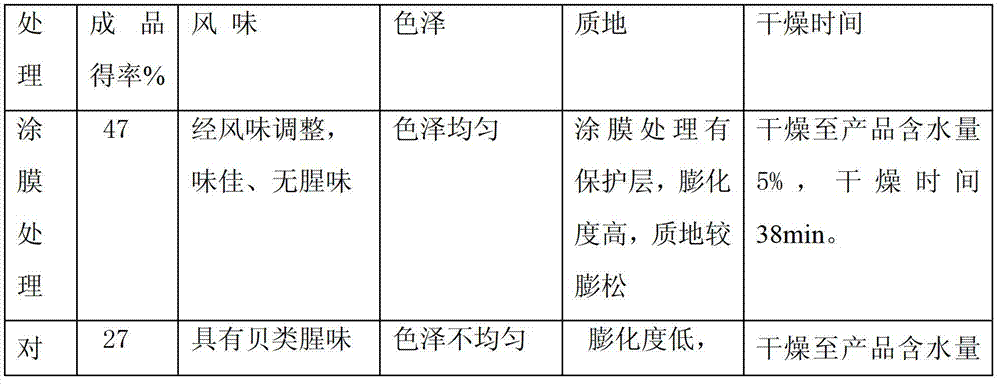

Embodiment 2

[0032] The specific steps of drying and processing shellfish into snack food are as follows:

[0033] (1) Pretreatment: wash the shellfish.

[0034] (2) blanching: blanching with 80-90 ℃ water for 2 minutes, shellfish shells just opened, cool, take the meat, and drain and control the water.

[0035] (3) Coating: Soak the shellfish in the seasoning coating solution for 30 minutes, take it out and drain, so that a film is formed on the surface of the shellfish. At the same time, seasoning is added to the coating liquid to improve the taste of snack food. The ratio of coating liquid and seasoning is: sodium alginate 3%: seasoning 97%.

[0036] (4) Hot air and microwave combined spray drying: turn on the electric heating and fan before drying, until the inlet air temperature reaches 50 ℃, put in shellfish particles, adjust the wind speed to 15m / s, the microwave output power is 4w / g, and the wind speed is adjusted later. The total drying time of 10m / s drying is 38min. to a prod...

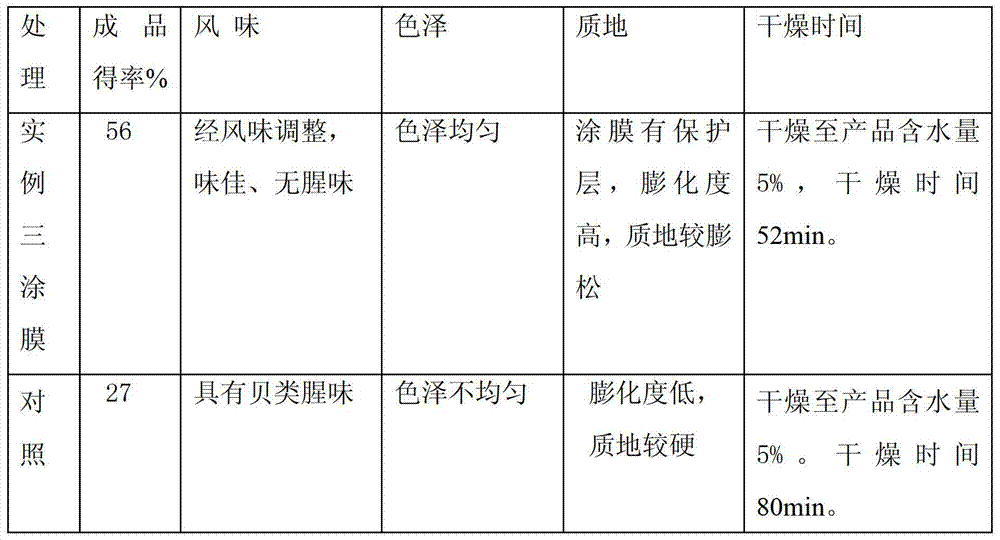

Embodiment 3

[0039] The specific steps of drying and processing shellfish into snack food are as follows:

[0040] (1) Pretreatment: wash the shellfish.

[0041] (2) blanching: blanching with 80-90 ℃ water for 3 minutes, and shelling the shells immediately after opening, cooling, taking the meat, and draining to control the water.

[0042] (3) Coating: Soak the shellfish in the seasoning coating solution for 30 minutes, take it out and drain, so that a film is formed on the surface of the shellfish. At the same time, seasoning is added to the coating liquid to improve the taste of snack food. The ratio of coating liquid and seasoning is: sodium alginate 4%: seasoning 96%.

[0043] (4) Hot air and microwave combined spray drying: turn on the electric heating and fan before drying, until the inlet air temperature reaches 50 ℃, put in shellfish particles, adjust the wind speed to 15m / s, the microwave output power is 4w / g, and the wind speed is adjusted later. The total drying time of 10m / s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com