Inorganic nano-material modified asphalt and preparation method thereof

A technology of inorganic nanomaterials and modified asphalt, which is applied in building thermal insulation materials, building components, buildings, etc., to achieve the effects of reducing maintenance costs, improving UV resistance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

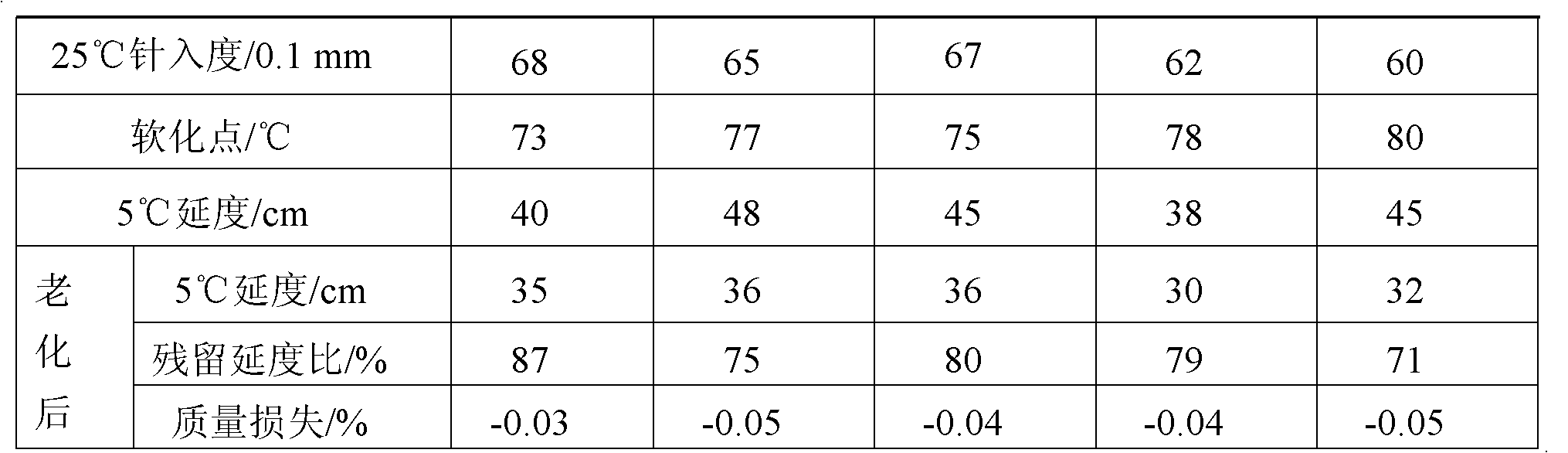

[0016] Will 470g 90 # The road asphalt was heated to 175-180°C, and at a shear rate of 3500r / min, 1.0g of carbon nanotubes and 29.0g of nano-cerium oxide were added in sequence, and the mixing time was 2.5h to obtain inorganic nanomaterial-modified asphalt.

[0017] The modifier is dissolved evenly, and the performance of the modified asphalt is tested. See Table 1.

Embodiment 2

[0019] Will 480g 90 # The road asphalt was heated to 175-180°C, and at a shear rate of 3800r / min, 1.5g of carbon nanotubes and 18.5g of nano-cerium oxide were added in sequence, and the mixing time was 2h to obtain inorganic nanomaterial-modified asphalt.

[0020] The modifier is dissolved evenly, and the performance of the modified asphalt is tested. See Table 1.

Embodiment 3

[0022] Will 490g 90 # The road asphalt was heated to 175-180°C, and at a shear rate of 4500r / min, 2.5g of carbon nanotubes and 7.5g of nano-cerium oxide were added in sequence, and the mixing time was 1.8h to obtain inorganic nanomaterial-modified asphalt.

[0023] The modifier is dissolved evenly, and the performance of the modified asphalt is tested. See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com