Ferrous and carbonaceous dust cyclic reutilization process and equipment

A carbon dust and dust technology, which is applied in the improvement of process efficiency, furnace and blast furnace details, etc., can solve the problems of poor wettability of dust and water, cannot reduce dust, and serious dust phenomenon, so as to achieve strong system adaptability to changes, The effect of promoting the antegrade and strengthening of the blast furnace and avoiding the fluctuation of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

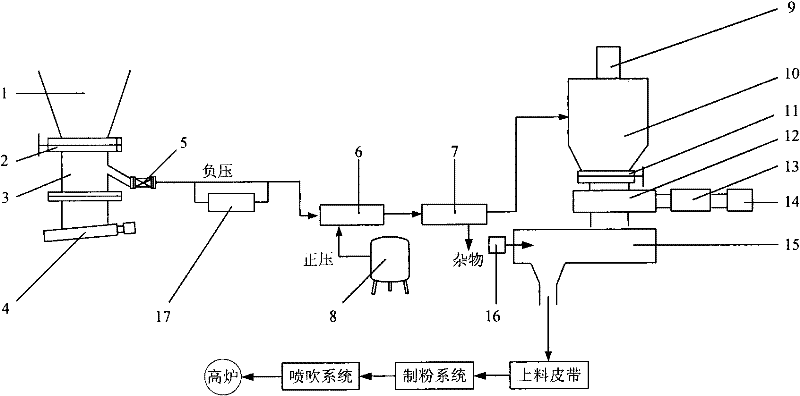

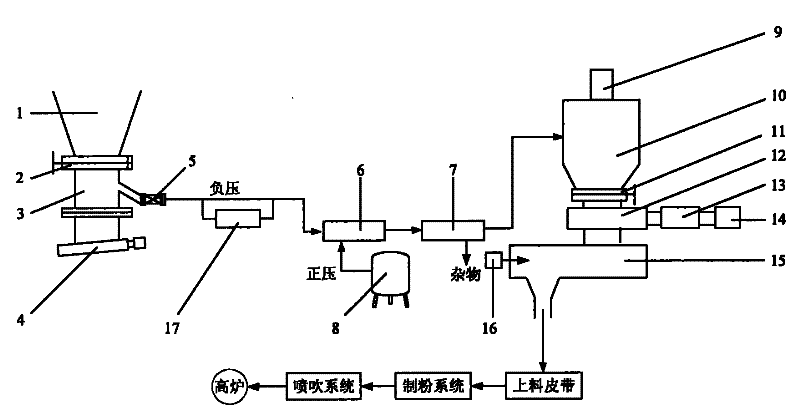

[0029] Attached below figure 1 The present invention is further described.

[0030] Such as figure 1 As shown, dust collection tank→suction and discharge truck→filter→powder storage tank→star unloader→two-wheel stirring humidifier→feeding belt→blast furnace pulverizing system→injection system→blast furnace.

[0031] The present invention adopts the method of "uniformly mixing one or more iron-containing dusts with the raw coal for blast furnace injection, and spraying them into the hearth from the tuyere of the blast furnace after passing through the pulverizing system and the injection system". Dust is recycled.

[0032] The present invention consists of three parts: an ash collecting system, an ash loading system and an ash discharging system.

[0033] Such as figure 1 As shown, the ash collection system includes: a dust collecting tank 1, a gate valve 2, a distributor 3, a butterfly valve 5, and a suction and discharge vehicle 6 to form a (collection) ash system.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com