Hydrogen sulfide corrosion-resistant steel for petroleum drill rod and manufacturing method for hydrogen sulfide corrosion-resistant steel

A technology for oil drill pipes and manufacturing methods, which is applied to drill pipes, drill pipes, and earthwork drilling and production, and can solve problems such as test evaluation, reduced sulfur resistance of joints, failure to pass sulfur resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

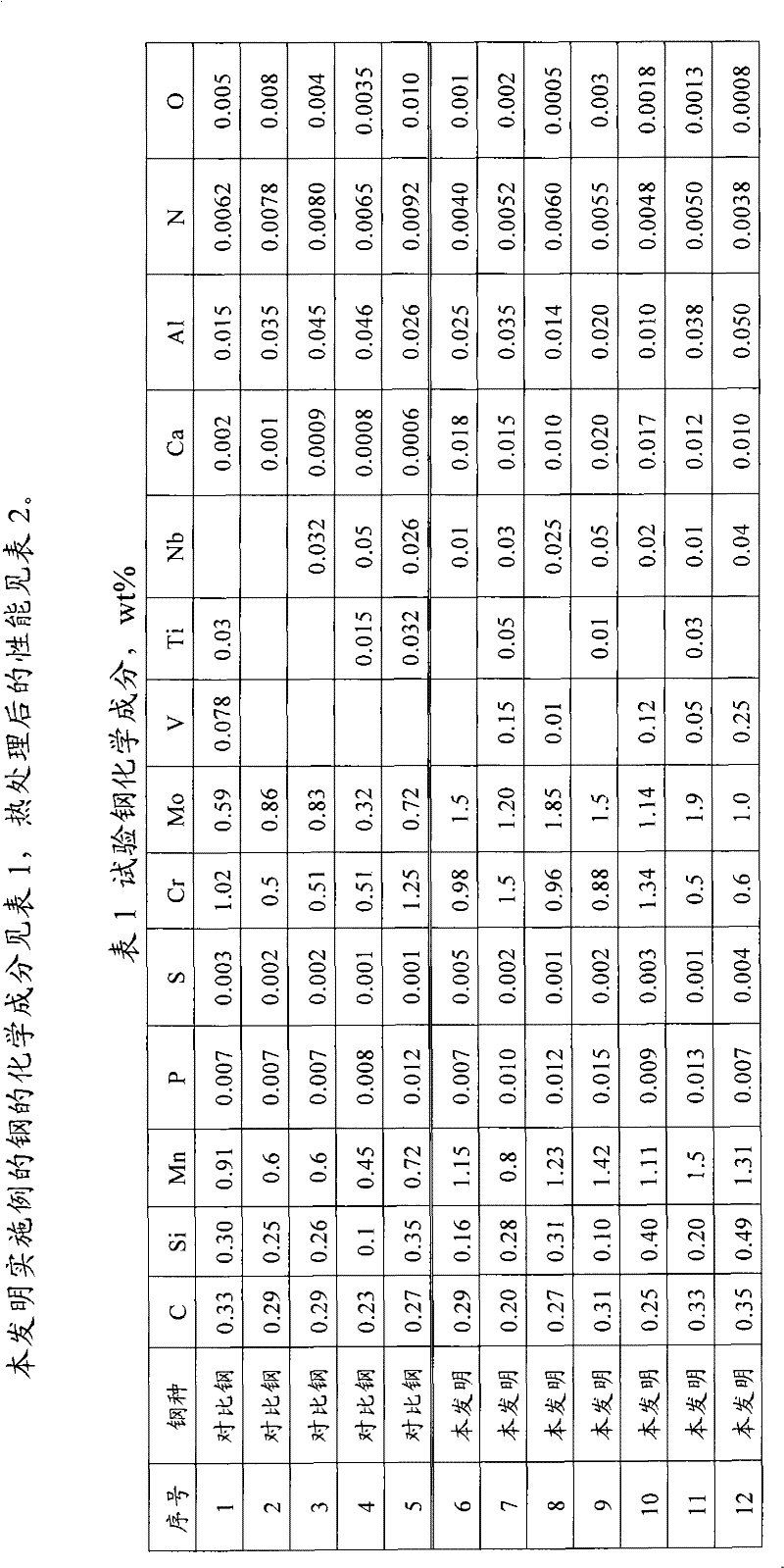

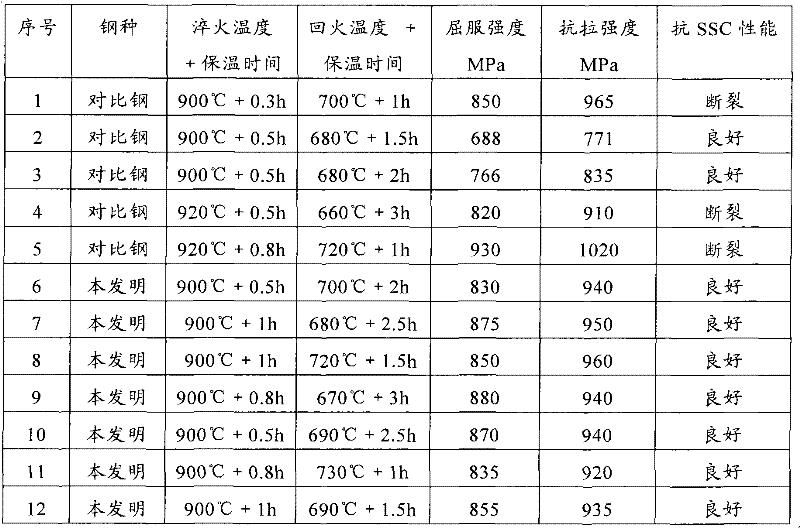

[0027] The commonly used Cr-Mo steel, Cr-Mn-Mo steel and the steel grade of the present invention are compared below, and their chemical compositions are shown in Table 1.

[0028] It is smelted in an electric furnace, and LF+VD double vacuum treatment is adopted after smelting, [N]≤30ppm, [O]≤10ppm after LF refining;

[0029] The sedation time after VD vacuum treatment was 10±5 minutes;

[0030] Ca treatment is carried out by feeding Si-Ca wire;

[0031] In continuous casting, the casting speed of the continuous casting slab is controlled at about 2.0m / min;

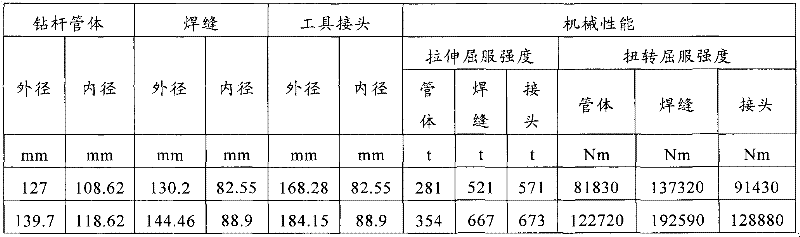

[0032] The above materials are hot-rolled into seamless steel pipes and thickened at both ends, then quenched after heating at 900±50°C for 0.5 to 1 hour, and then tempered at 700±20°C for 1 to 3 hours. Drill pipe body.

[0033] Compared with the comparison steel, the drill pipe body of the present invention has higher Mo, which improves the tempering stability of the material, so it still has higher strength after te...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap