Pollutant discharging and dredging device for excavator

A dredging device and excavator technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem that the body is difficult to disassemble, transport and install, the flexibility is limited, and dredging and dredging are powerless To achieve the effect of convenient and quick transfer, improve work efficiency, and solve the problems of power shortage and inconvenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

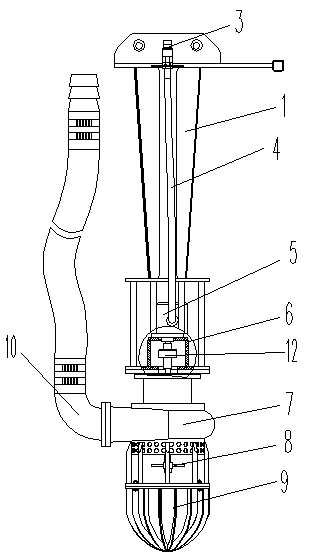

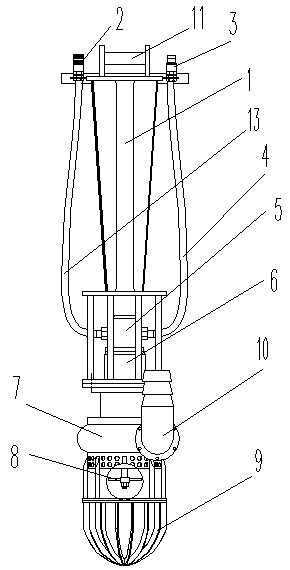

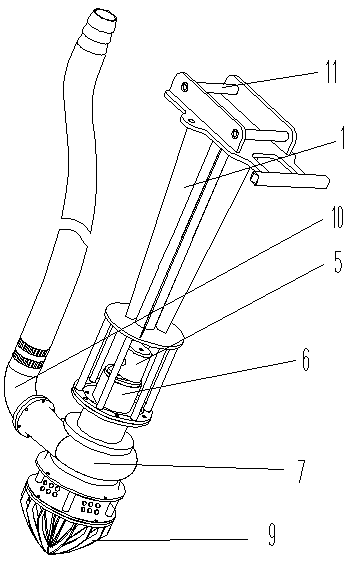

[0022] Such as Figure 1 to Figure 3 The shown sewage and desilting device for excavators includes: a connecting frame 1 for connecting with an excavator working device stick and connecting rod or a quick change device, a one-way rotating hydraulic motor 5, and a hydraulic motor mounting base 6 , mud pump 7, sewage pipe 10, coupling 12, oil inlet and oil return pipes 4, 13, hydraulic quick change joints 2, 3 of oil inlet and oil return pipes, and the hydraulic motor mount 6 is fixed on the mud pump 7 On the housing, the hydraulic motor is fixed on the hydraulic motor mount 6; the power output shaft of the hydraulic motor 5 is connected to the power input shaft of the mud pump 7 through an elastic coupling 12, and one end of the connecting frame 1 is provided It has a cage-shaped frame and is fixed on the casing of the mud pump 7. The hydraulic motor 5 and the hydraulic motor mounting base 6 are placed in the cage-shaped frame. Or the connecting shaft 11 connected by the quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com