Super-high flow return-oil defoamer

A defoamer and flow rate technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as large oil return resistance, oil pollution, poor defoaming effect, etc., to prevent Bubbles, slowing down the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

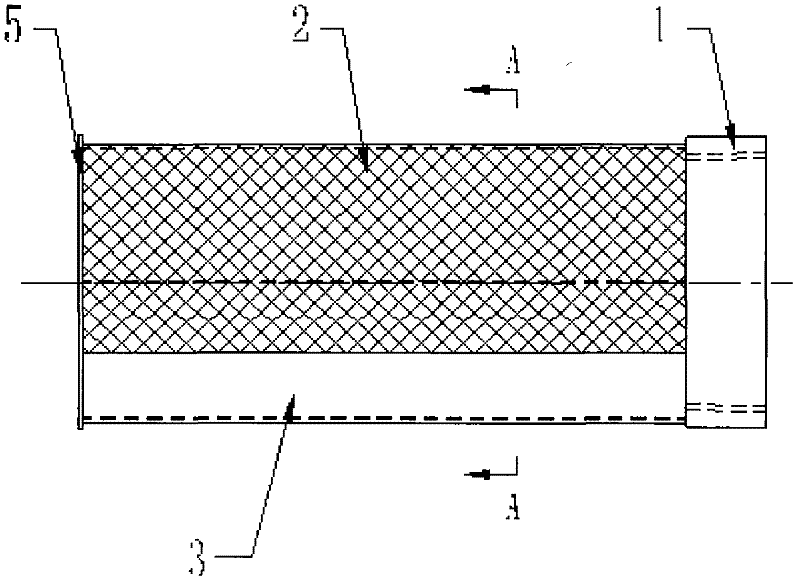

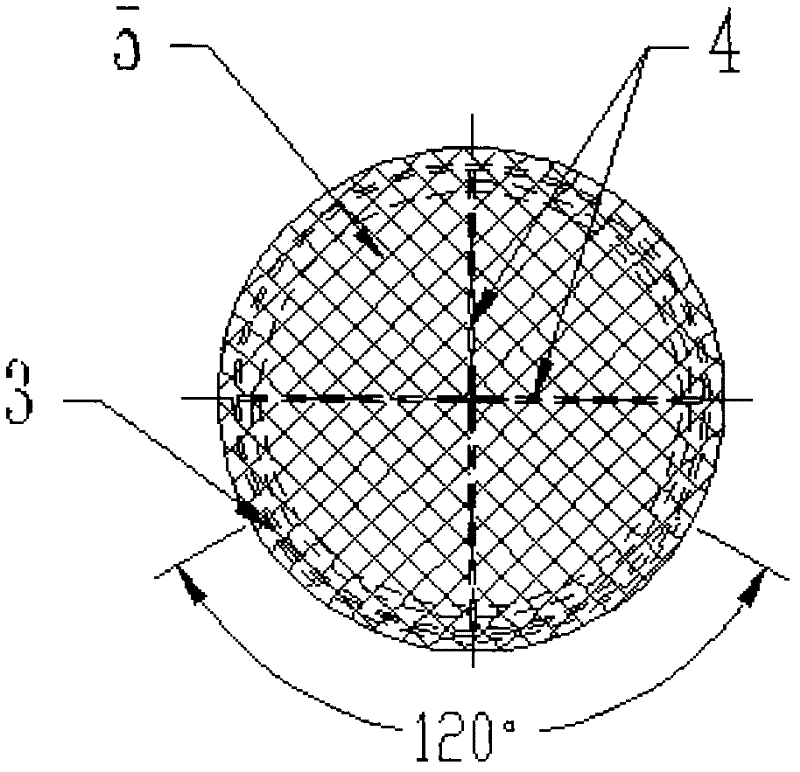

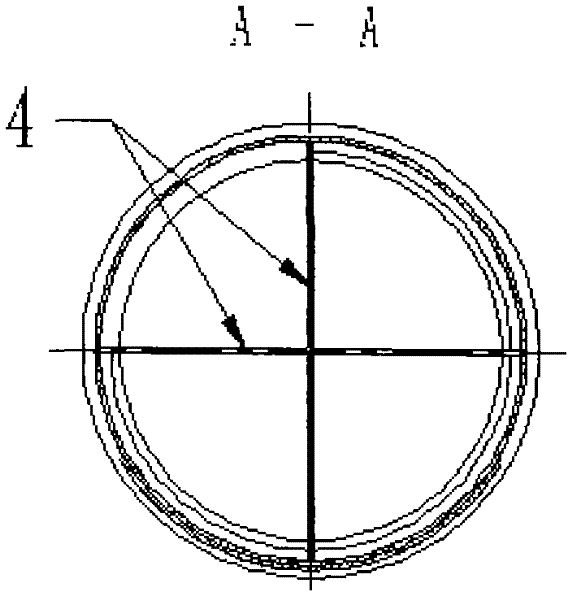

[0016] The present invention designs a super-large flow oil return defoamer, which is a cylindrical structure as a whole. The defoamer includes: a base 1, a shell 2, a baffle 3, a cross-shaped partition 4, and a bottom plate 5; the base 1 passes through 6" The NPT internal thread is connected to the oil return pipe inside the fuel tank, which can also ensure the sealing of the joint while playing the role of connection. The fixed connection between the base 1 and the shell 2 is welding, and the other end of the shell 2 is fixedly connected with the bottom plate 5. For welding, the connection mode between the cross-shaped partition 4 and the housing 2 is welding, the connection mode between the baffle plate 3 and the housing 2 is welding, and the baffle plate 3 is located at an angle of 120° in the axial direction of the outer side of the housing 2. The housing 2, the cross-shaped partition Plate 4, bottom plate 5 materials are all stainless steel perforated plates, and the hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com