LED (light emitting diode) lamp tube

A technology of LED lamps and lamps, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of affecting the heat dissipation effect and reducing the service life of LED lamps, and achieves easy wiring, simple structure, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

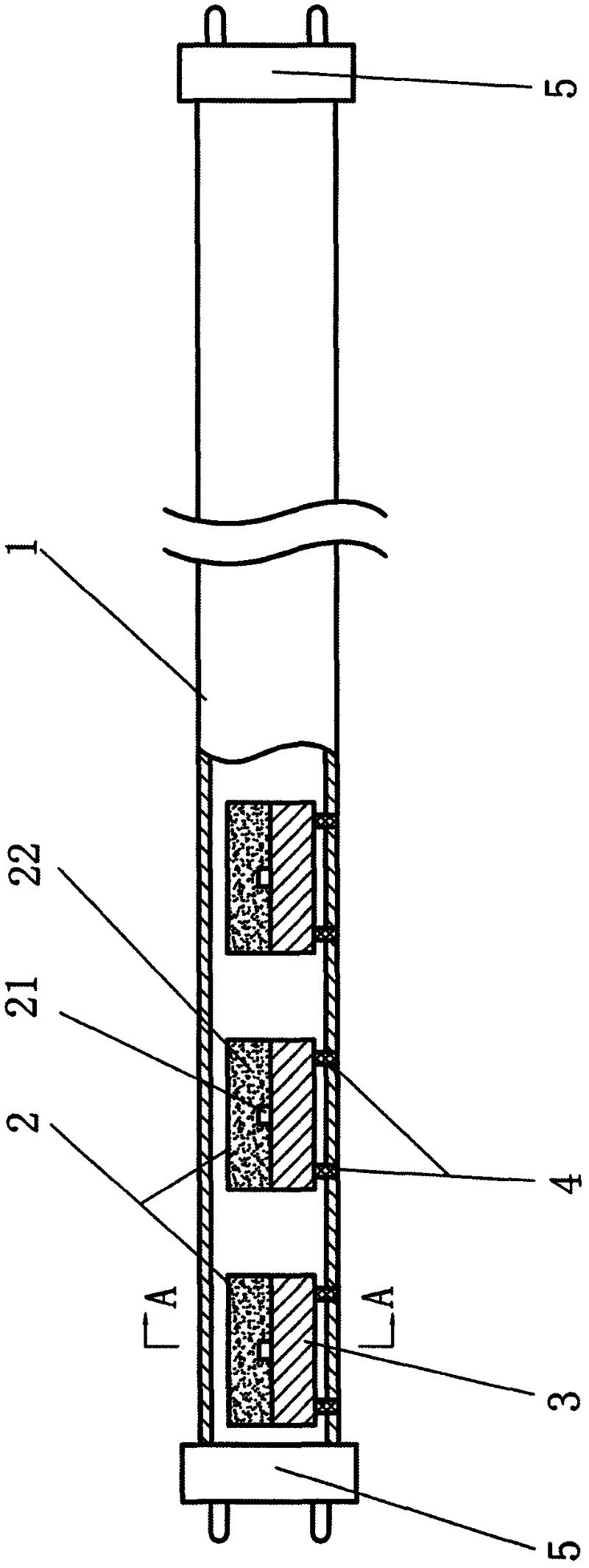

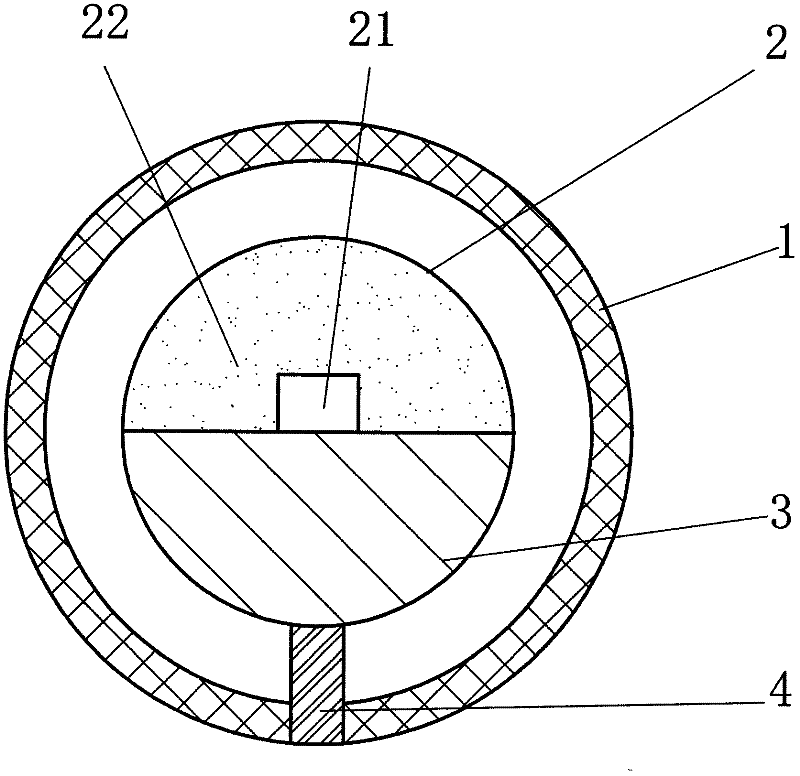

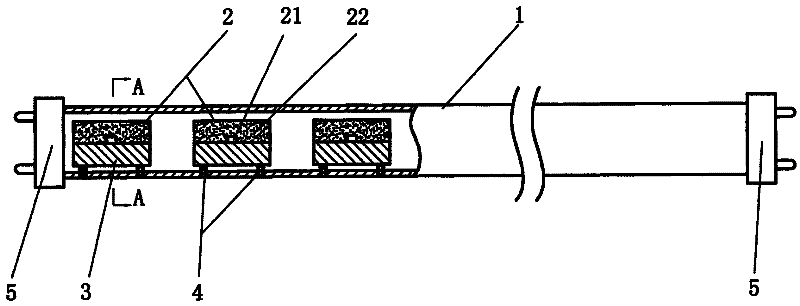

[0016] Example: see figure 1 , figure 2 .

[0017] An LED light tube, comprising a light-transmitting shell 1, lamp caps 5 located at both ends of the light-transmitting shell 1 for providing power, and an LED unit 2 arranged inside the light-transmitting shell 1, the LED unit 2 includes an LED chip 21 and The encapsulating resin 22 covering the LED chip, each LED unit 2 is arranged extending along the axis of the lamp tube, the lower part of the LED unit 2 is connected to the heat dissipation block 3 , and the lower end of the heat dissipation block 3 is provided with a hole extending to the outside of the light-transmitting shell 1 Leg 4.

[0018] Some manufacturers will connect heat sinks at the lower part of LED unit 2, and then connect each heat sink, and emit it through the lamp caps at both ends of the lamp tube. This kind of heat dissipation structure design requires that all heat sinks be connected. , will affect the cooling effect.

[0019] The structural design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com