Radiating structure and spotlight with radiating structure

A technology of heat dissipation structure and heat sink, applied in lighting and heating equipment, components of lighting devices, cooling/heating devices of lighting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

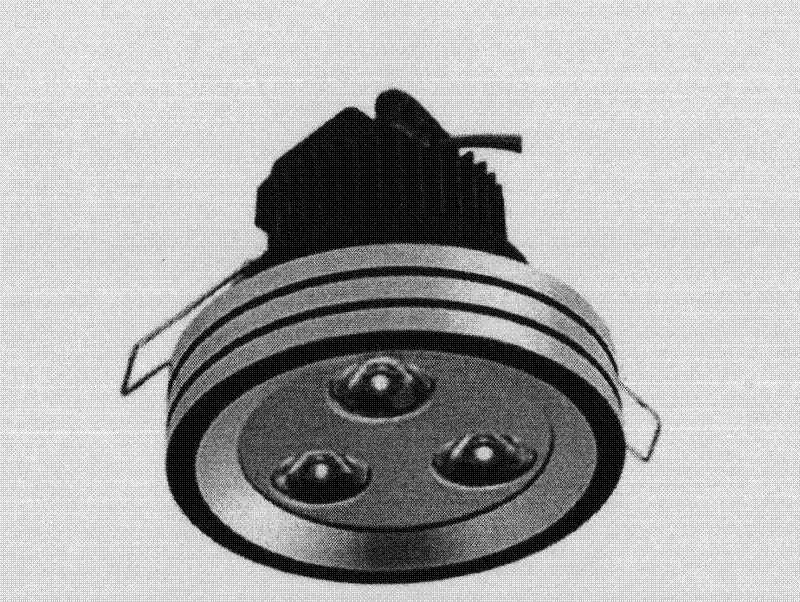

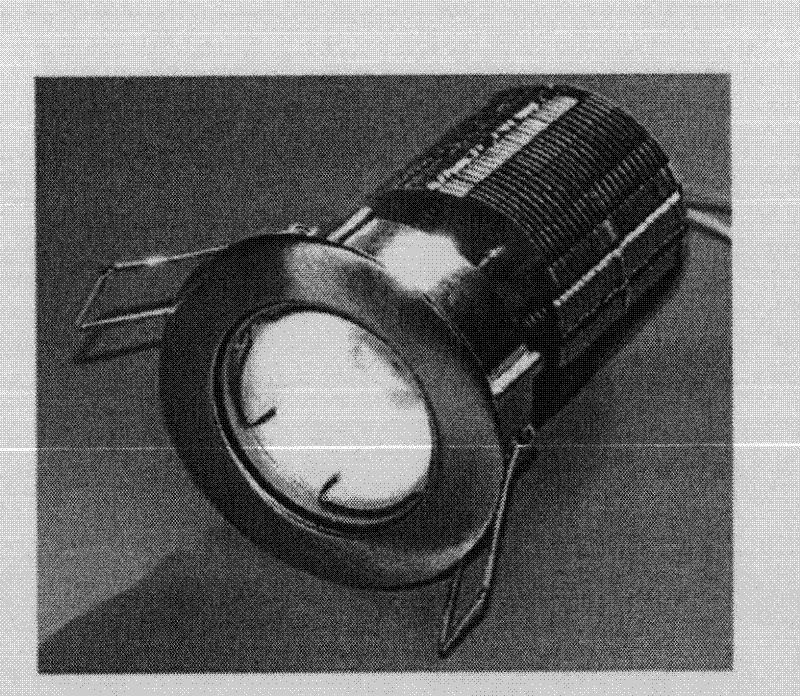

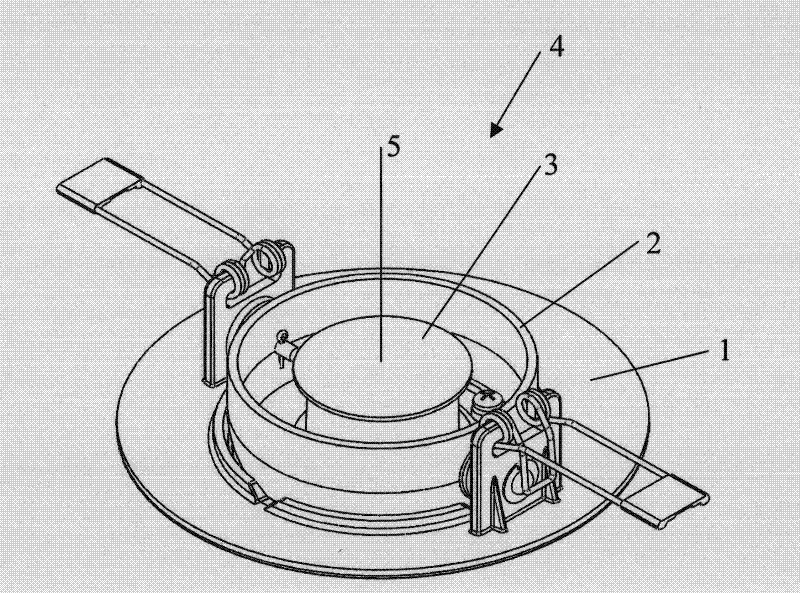

[0025] Figure 3a It is a perspective view of the spotlight 4 (without heat dissipation structure installed). The spotlight comprises a lamp body 3, a mounting ring 1 for installing the spotlight, and a moving ring 2 for axial rotation on the side. And the common axis 5 (shown by dotted line) of the above three. The spotlight is installed on the ceiling (or called the suspended ceiling) through the assembly opening and the heat dissipation structure is arranged in the space between the ceiling and the suspended ceiling, such as Figure 3b shown.

[0026] Figure 4a is the first state of the heat dissipation structure 100 according to the present invention. The heat dissipation structure according to the present invention is designed to be adjustable. In the first state, the heat dissipation fins 6 installed in the heat dissipation structure behind the lamp body 3 are in a folded state, wherein each heat dissipation fin 6 surrounds the heat conduction base 7 closely with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com