Temperature self-compensating type fiber grating strain transducer

A technology of strain sensor and optical fiber grating, which is applied in the field of temperature self-compensating optical fiber grating strain sensor, can solve the problems of large calculation error, easy false alarm, difference in temperature sensing speed between temperature sensor and strain sensor, etc., to prevent oxidation or Effects of corrosion, reduced test cost, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

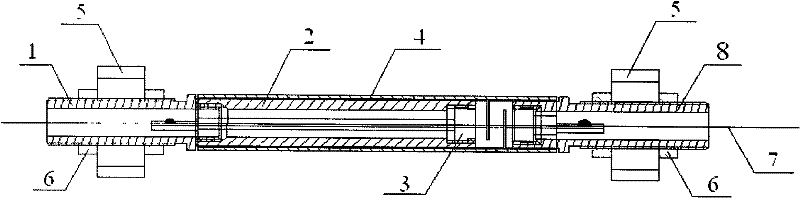

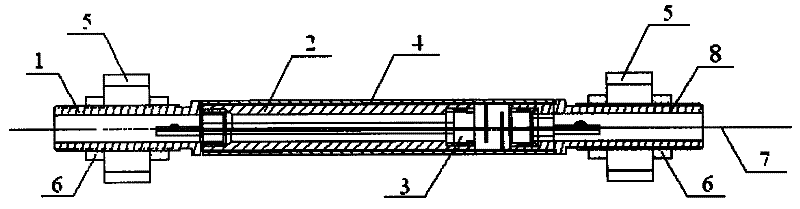

[0040] A kind of fiber grating strain sensor, its structure is as figure 1 As shown, it includes two mounting seats 5 provided with opening grooves in the longitudinal direction, the first coil 1 is connected to the metal pipe 2, the metal pipe 2 is connected to the left end of the elastic rod 3, and the fiber grating 7 is fixed on both ends of the elastic rod 3, The right end of the elastic rod 3 is connected to the second screw tube 8, the outer side of the elastic rod 3 is covered with an outer tube 4, the first screw tube 1 and the second screw tube 8 are respectively provided with two nuts 6, and the two screw tubes 6 are stuck on the mounting seat In the opening groove of 5, four nuts 6 are respectively distributed on both sides of the two mounting bases 5, and the fiber grating strain sensor is fixed by the nuts 6. The two mounting bases 5 are welded or fixed on the substrate by expansion nails.

[0041] The innovation of the present invention is that when the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com