Portable rock mass structural plane direct shear test apparatus for field and indoor use

A technology of direct shear tester and structural surface, applied in the direction of applying stable shear force to test the strength of materials, instruments, scientific instruments, etc., can solve the problems of structural surface shear strength parameter error, disturbance, structural surface dislocation, etc. , to achieve the effect of eliminating human error, eliminating error angle and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with example and accompanying drawing.

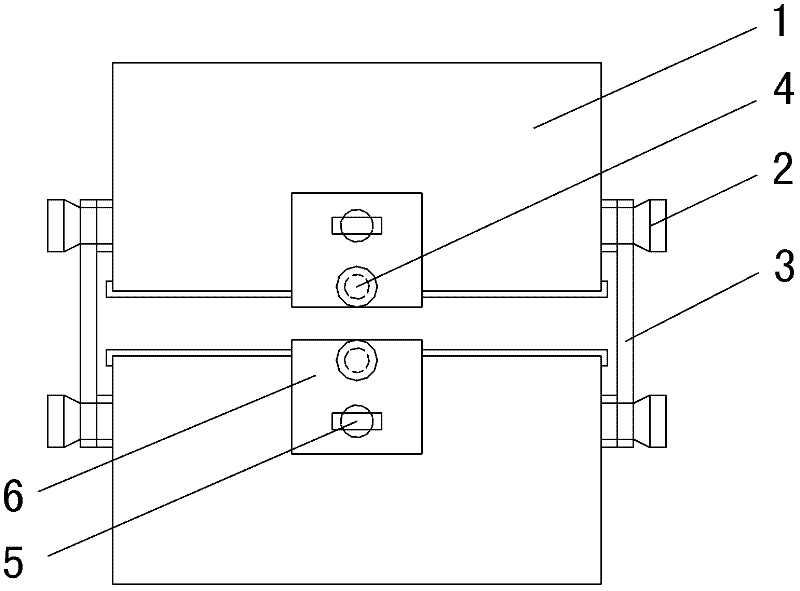

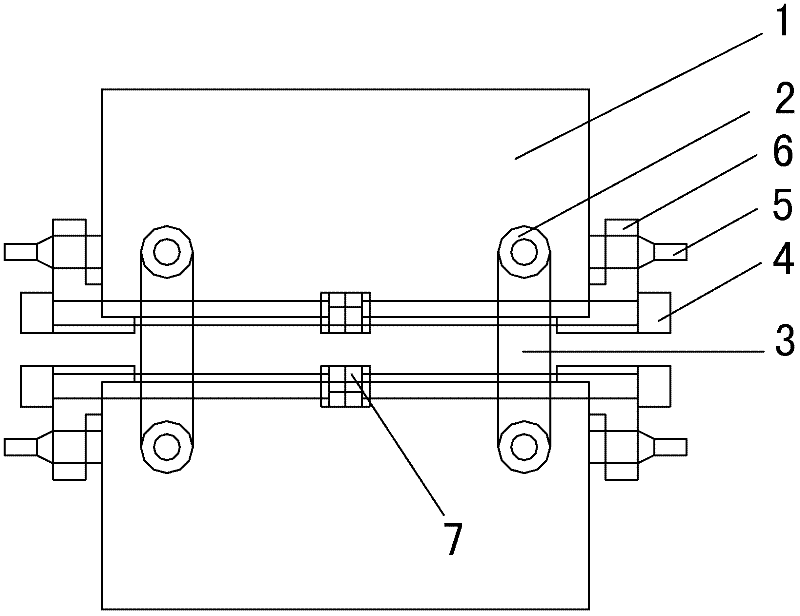

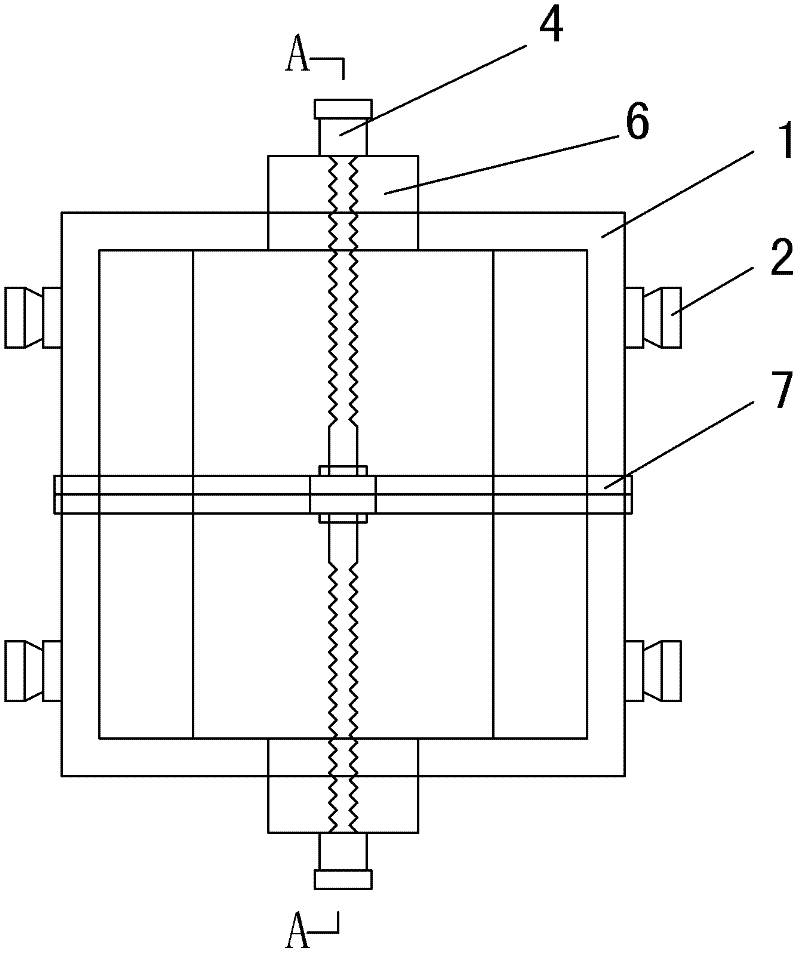

[0070] The present invention provides a portable on-site and indoor dual-purpose direct shear tester for rock mass structural surfaces (referred to as a direct shear tester), which is quite different from the existing portable direct shearer in terms of design ideas. The structure of the direct shear tester is as follows: Figure 1 to Figure 9 Shown: including sample preparation shear box and shear test device. Among them, the sample preparation and shearing box has a simple structure and is easy to operate. It combines the structural surface sample preparation and the shearing process into one, which optimizes the test process, ensures the accuracy of the test, eliminates the error angle of the structural surface sample preparation, and maximizes the accuracy of the test. The interference of human factors on the structural plane is greatly reduced. The design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com