Mixed flow assembly production scheduling control method based on bee society self-organization model

A technology for production scheduling and control methods, which is applied in adaptive control, general control systems, control/regulation systems, etc., and can solve problems such as low neighborhood search accuracy, poor control effect, and low solution efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

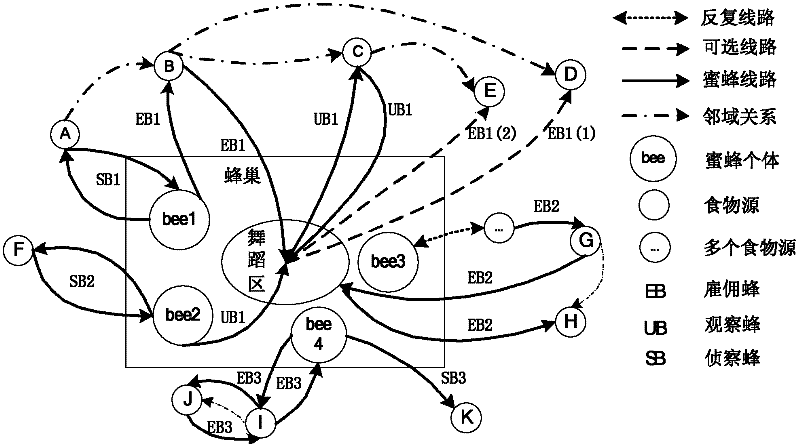

Method used

Image

Examples

example

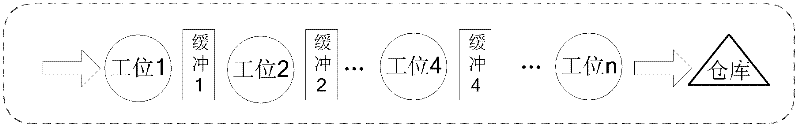

[0142] Example: The final assembly line C of a motor assembly workshop adopts a mixed-flow production method. The line assembles 5 kinds of products, including 10 workstations. The daily planned output is 120 units of product A, 140 units of product B, 40 units of product C, and 60 units of product D. , E product 80 units, switching time is 5. The minimum production cycle available is 6A, 7B, 2C, 3D, 4E, with a total of 22 workpieces. The processing time of each product corresponding to the station is shown in Table 1.

[0143] Table 1 Workpiece processing schedule

[0144]

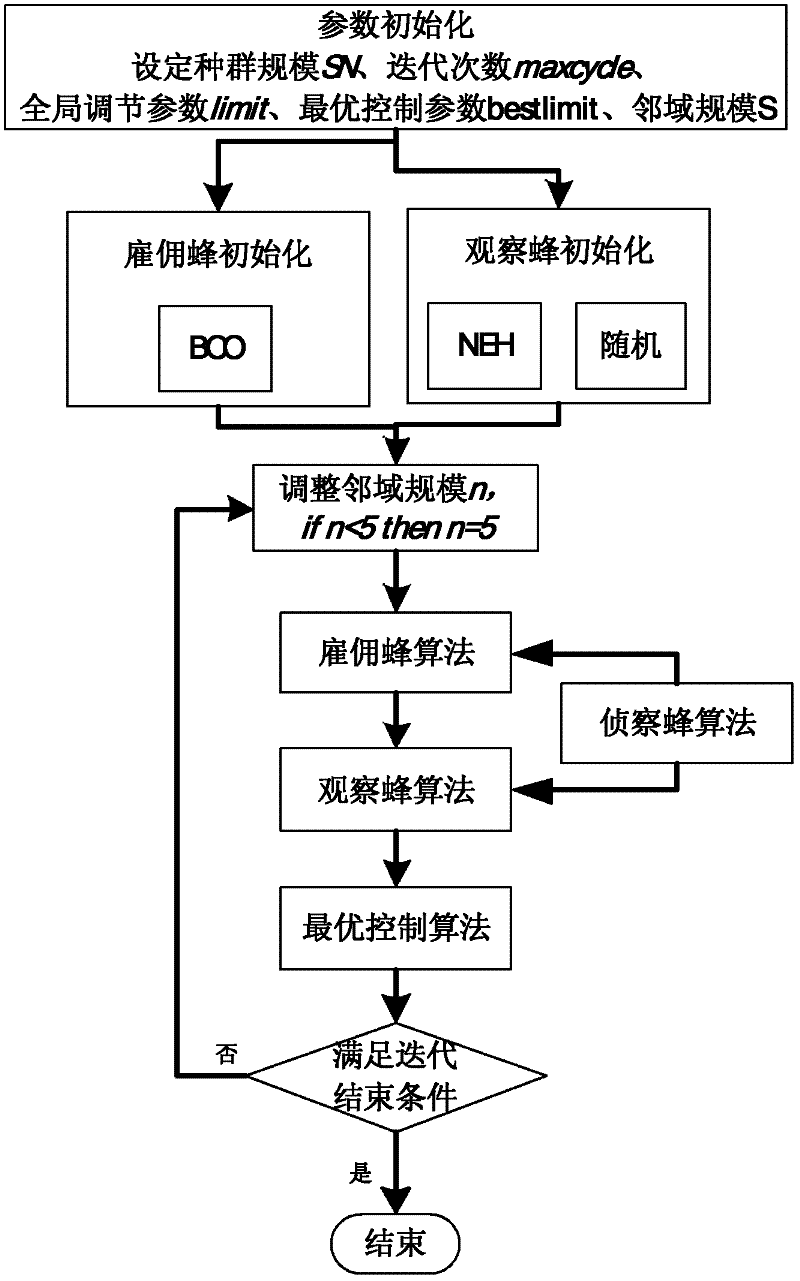

[0145] The parameter population size is 50, the number of iterations is 200, the limit is 6, the bestlimit is pop / 6, and the initial neighborhood size S=11. The embodiment takes the shortest completion time as the goal, and compares whether to include the consideration of switching time. One of the minimum production cycle sequences including switching time is {AAAABEBBBCDEBBDDCEBBEAA}, and one of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com