Method for evaluating performance reliability of numerical control equipment

A reliability and performance technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of declining reliability, accuracy and reliability of CNC equipment, reducing the production efficiency and utilization rate of CNC equipment, etc. Achieve the effect of improving efficiency and solving nonlinearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

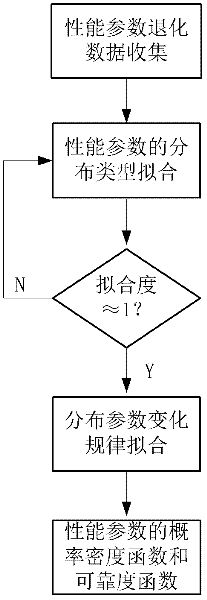

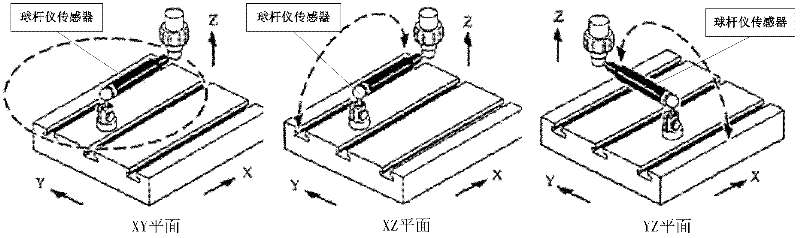

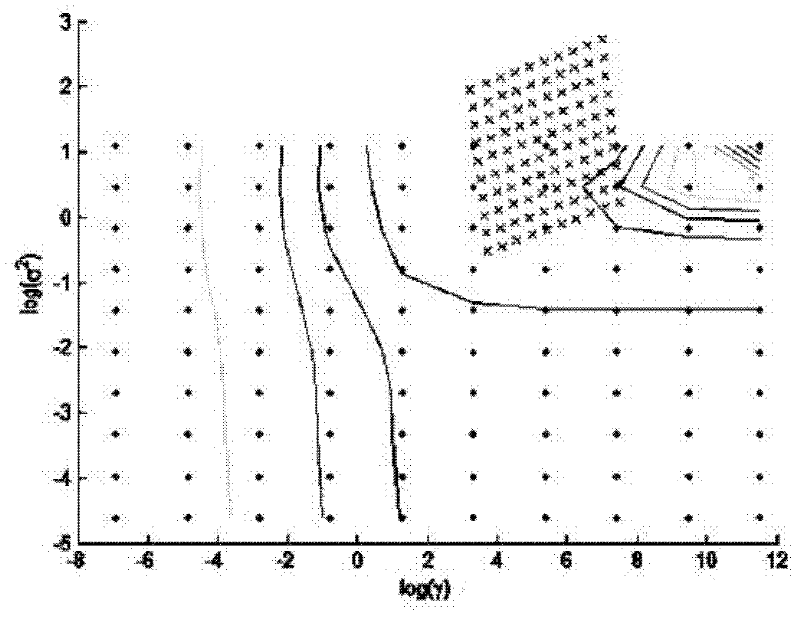

[0020] With the development of science and technology and the continuous improvement of manufacturing technology, many equipment and instruments have shown a trend of high reliability and long life. When carrying out life tests on these devices, the phenomenon of little failure data or "zero failure" often occurs, which cannot be solved by the traditional reliability evaluation method based on failure data. The functions completed by the product are characterized by its performance parameters, and the impact of the dynamic environment on the product is also reflected in the changes in the performance parameters. In many cases, there is an inevitable relationship between product failure and performance degradation, and product performance degradation can lead to Failure, it can be seen that the process of product performance degradation contains a large number of credible, accurate and useful key information related to product life. The reliability of the product can be evaluat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com