Method for quality testing and analysis of tube core of GaAs-based semiconductor quantum dot laser

A detection method and laser technology, applied in the direction of semiconductor lasers, single semiconductor device testing, lasers, etc., can solve the problems of small amount of information, complex equipment, high testing costs, etc., and achieve the effect of strong comparison and easy mastery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

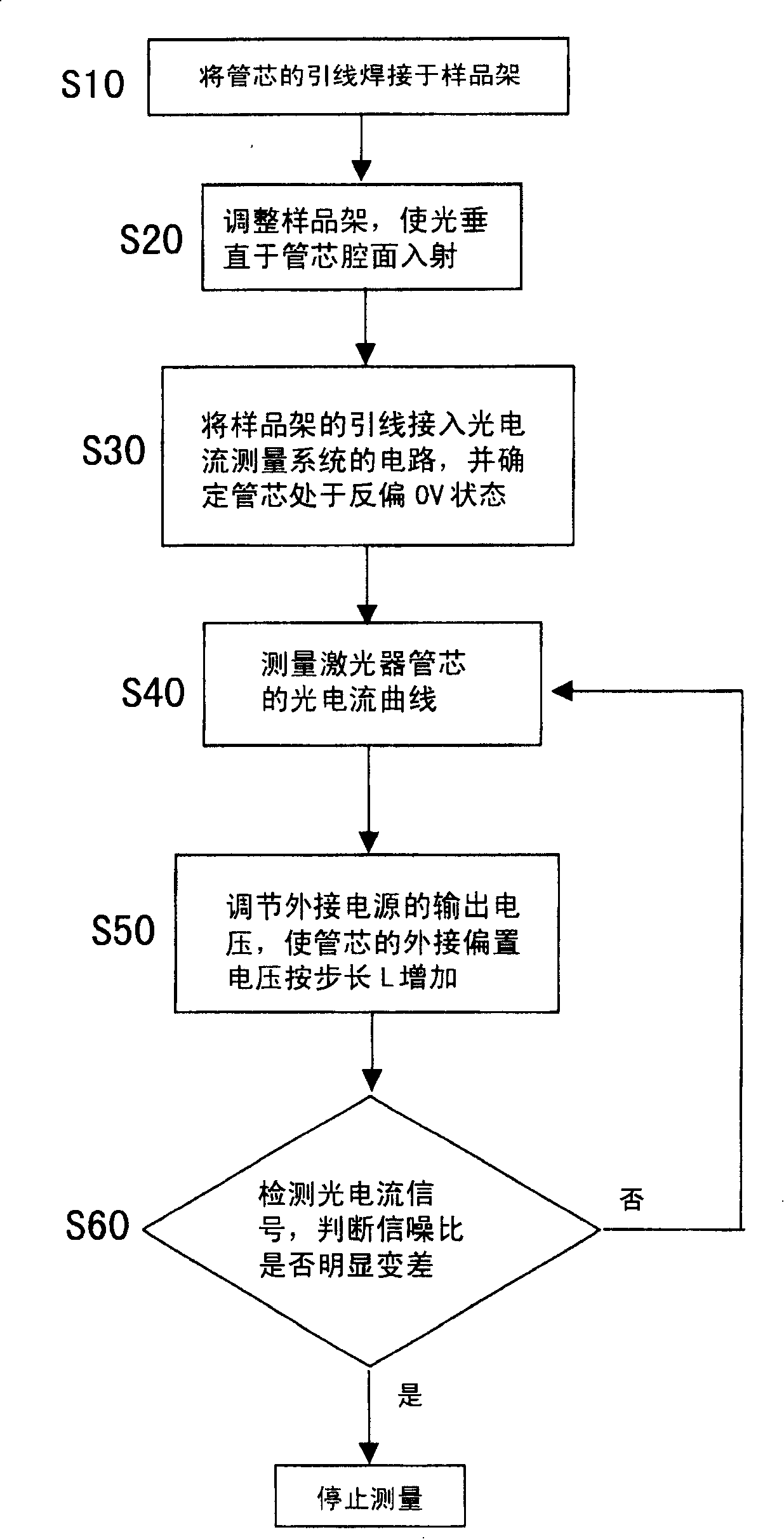

[0060] see again figure 1 and figure 2 Shown, the detection method of a kind of GaAs base semiconductor quantum dot laser die quality of the present invention:

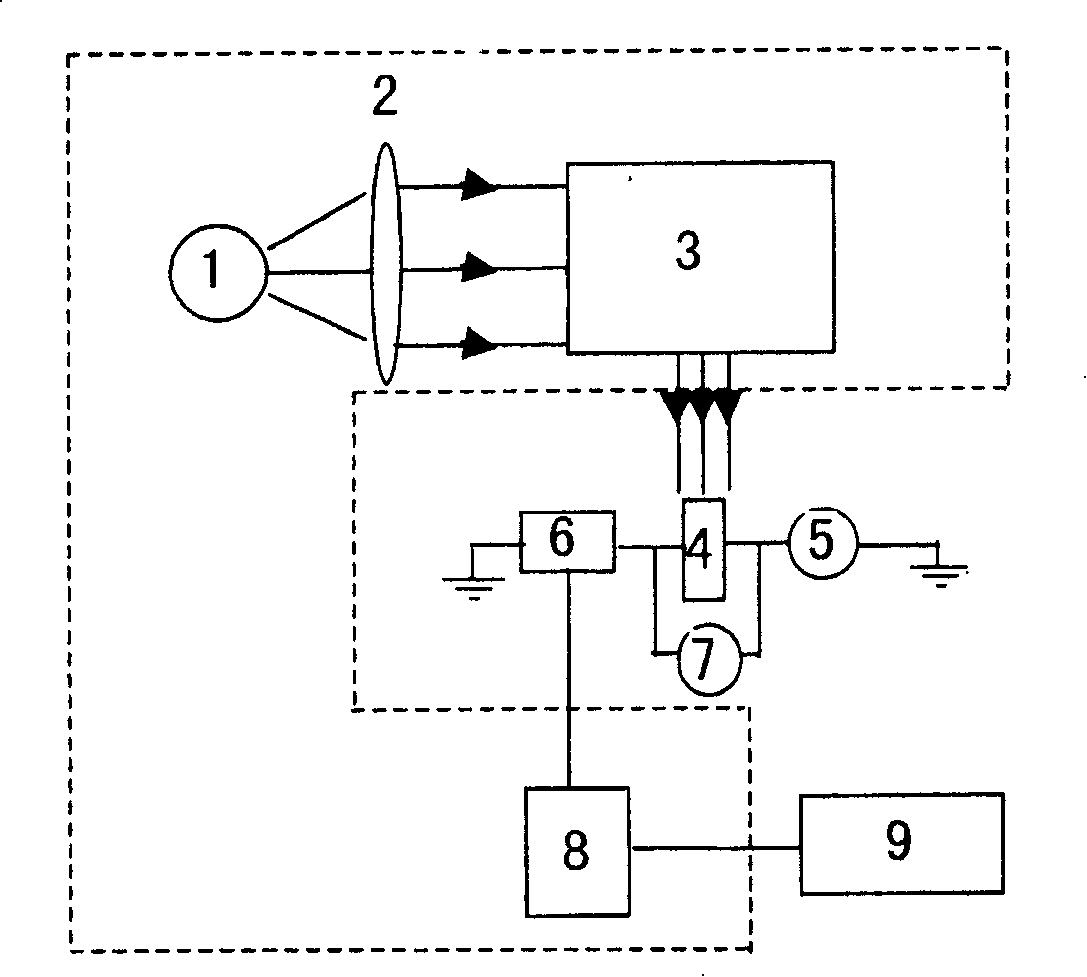

[0061] 1, adopt measuring method described in the present invention ( figure 1 )and figure 2 device shown. Among them, the tungsten lamp 1, the lens group 2, the Michelson interferometer 3, and the data acquisition circuit 8 are the main components of the Fourier transform infrared spectrometer. Finished product, its structure and operation method will not be repeated here. 4 is the laser die to be measured, 5 is the voltage source (for adding reverse bias to the laser die and providing the power supply of the preamplifier), 6 is the preamplifier (for small signal amplification), and 7 is the voltmeter (use Voltage monitoring at both ends of the tube core), and 9 is a computer (for the control and data processing of the Fourier infrared spectrometer).

[0062] 2. The measurement process of the photocurrent cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com