Bus duct jack box locking device

A locking device and plug-in box technology, applied in the installation of busbars, cables, electrical components, etc., can solve problems affecting installation efficiency, unfavorable batch installation, busway burning, etc., to improve product operation quality , Eliminate the effects of loose fixation and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

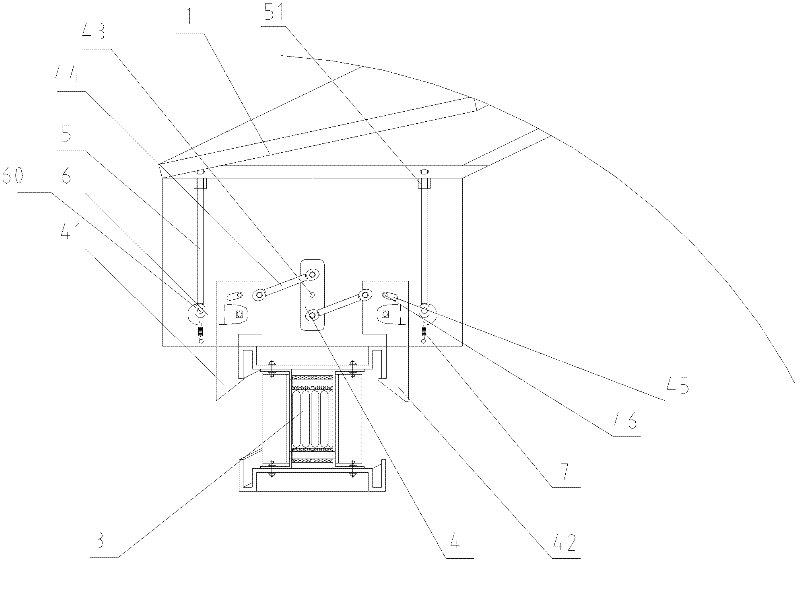

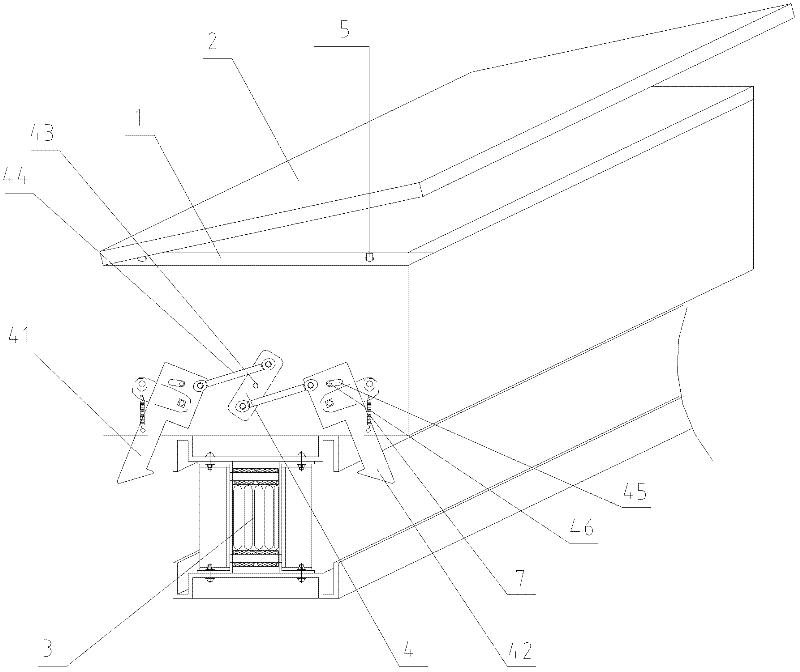

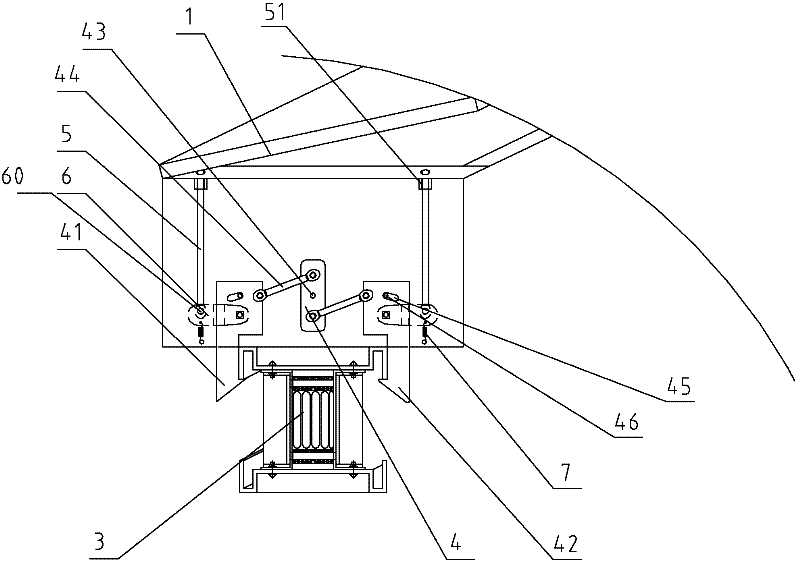

[0016] As shown in the figure, a locking device for a busway plug-in box includes a left locking hook 41 and a right locking hook 42 installed outside the box, a return spring 7, and the left and right locking hooks 41 and 42 are parallel Vertically arranged on the outside of the box body 1, one end of the left and right locking hooks 41, 42 extends below the box body 1; the left and right locking hooks 41, 42 are movable with the box body 1 connection; the return spring 7 is respectively located on the outer surfaces of the left and right locking hooks 451 and 42; both ends of the return spring 7 are fixedly connected to the box and the corresponding left and right locking hooks respectively. The left and right locking hooks 41, 42 are installed on the box body 1 through pin shafts, so that the left and right locking hooks 41, 42 can rotate on the box body 1; the box body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com