Vertical element single-cylinder entire foot machine

A component and vertical technology, which is applied in the field of vertical component single-cylinder footer, can solve the problem that the pins of electronic components are difficult to accurately insert into the PCB circuit board, which affects the insertion quality and insertion efficiency of the vertical plug-in machine. In order to improve the quality of insertion, high cost performance and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

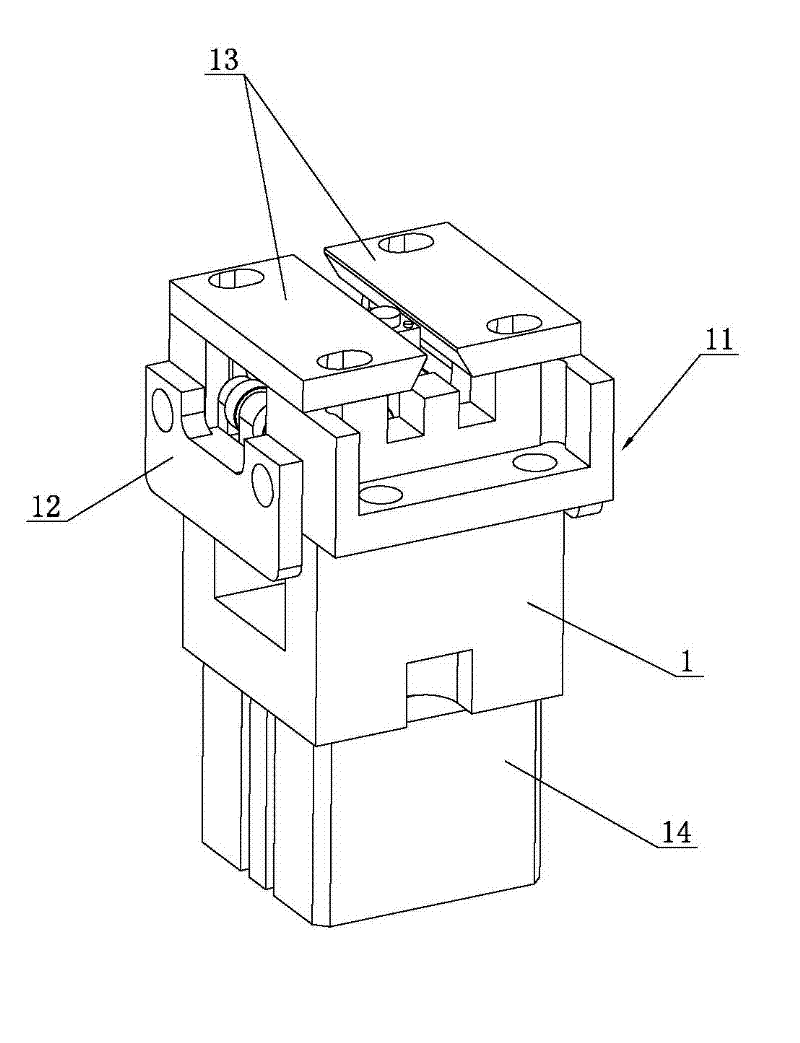

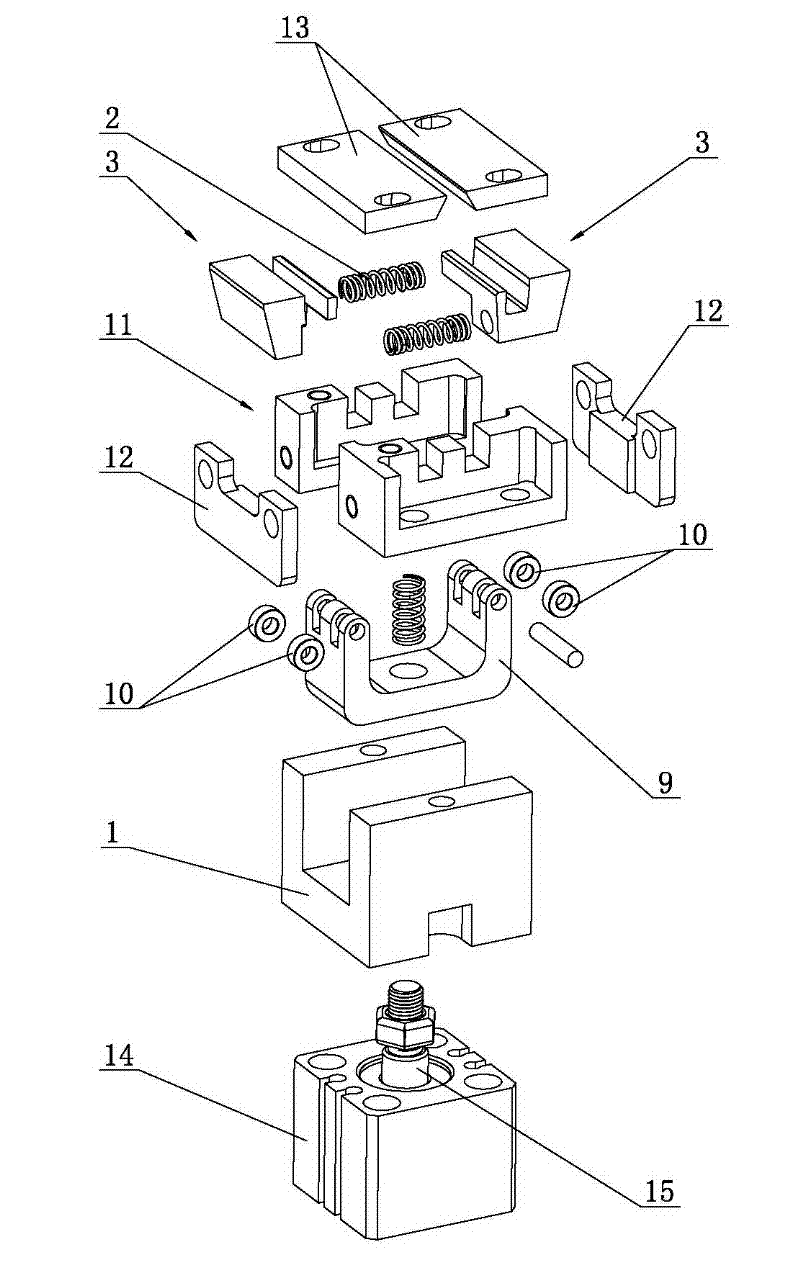

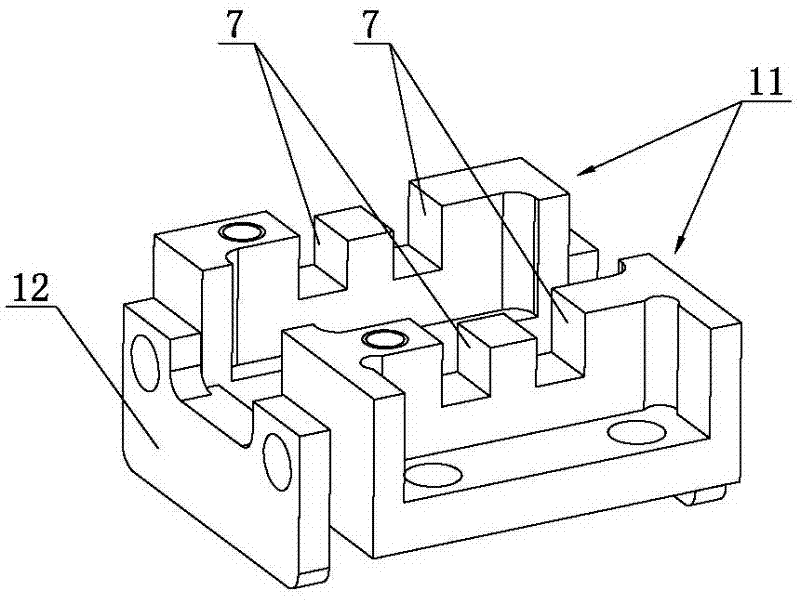

[0023] Such as Figure 1 to Figure 6 Shown, a kind of vertical component single-cylinder leg adjustment device, comprises the whole foot base 1, the first spring 2, the mounting seat installed on the whole foot base 1 and two whole foot blocks 3, each whole foot block 3 includes The whole foot body 4 that is movable installed on the mounting seat, the inner side wall of the whole foot body 4 is provided with a protruding block 5, and the outer end of the protruding block 5 is provided with a shaping bar 6, and the width of the protruding block 5 is smaller than the shaping bar. The length of the bar 6, there is an interval between the shaping bar 6 and the whole foot body 4, and the interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com