Device for transporting tabular goods

A technology for conveying plates and goods, applied in the field of equipment, can solve the problems of easy failure, requiring a large number of movable parts, and expensive equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

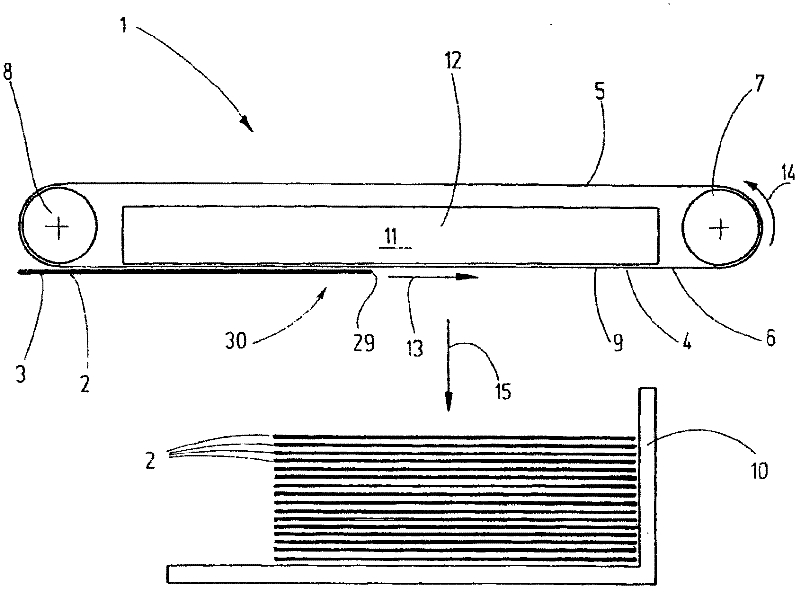

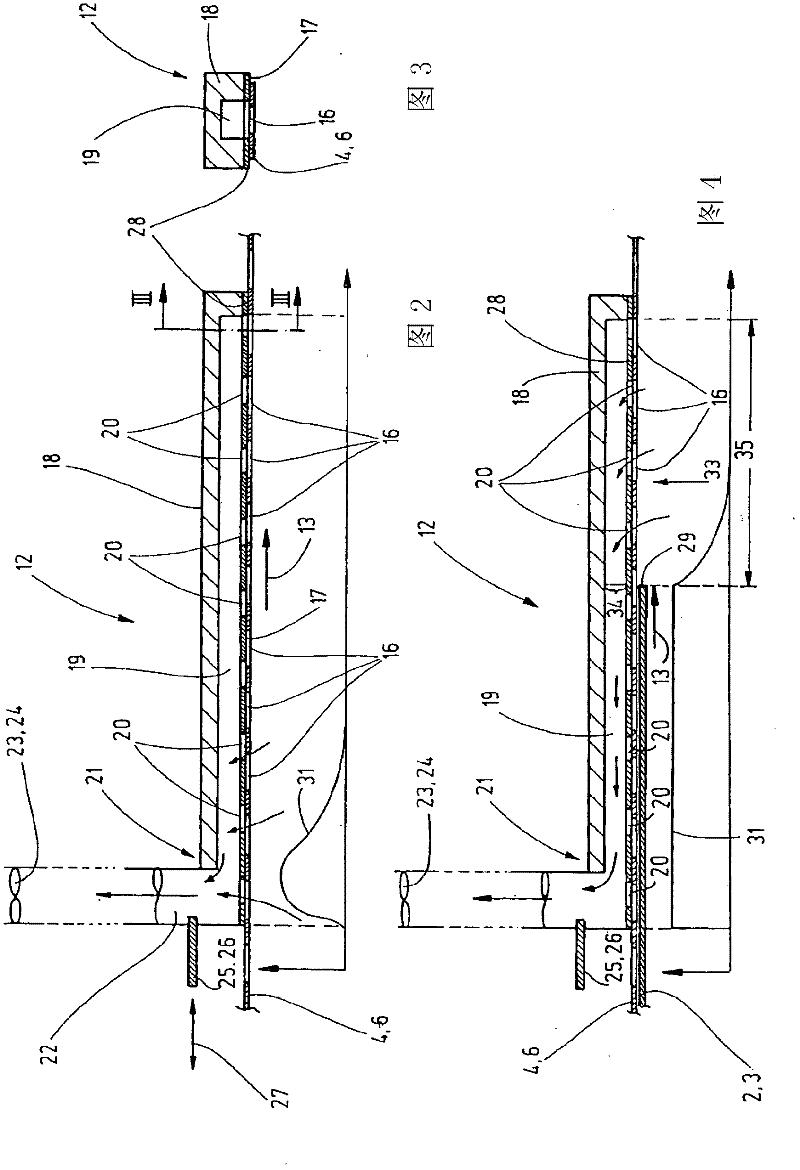

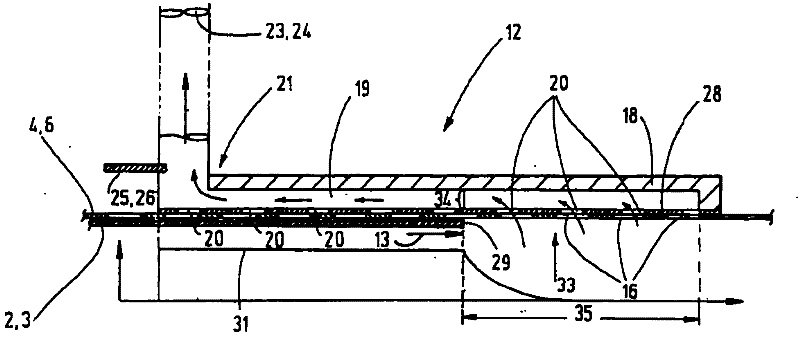

[0019] figure 1 A device 1 for conveying sheet-like goods 2 , in particular steel sheets 3 , is shown. Goods 2 can be transported and in particular stacked using the device 1 .

[0020] The device 1 has a conveyor 4 in the form of an endless branch (Trum) 5, which is preferably designed as a conveyor branch. The branch 5 has a plurality of conveyor belts 6 arranged laterally at a distance from one another, of which only one conveyor belt 6 will be discussed below. The rest of the conveyor belts 6 are designed in the same way and cooperate with the same type of components, which will be described in detail below, so that it will suffice only to describe the conveyor belt 6 with the corresponding components.

[0021] The conveyor belt 6 is guided by two deflection wheels 7 , 8 , at least one of which can be driven by means of a drive not shown. The lower branch 9 of the branch 5 is on the outside facing the stacker 10 for the goods 2 . The lower branch 9 formed by the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com