Rolling element screw device

A rolling element and lead screw technology, which is applied to transmissions, transmission parts, belts/chains/gears, etc., can solve the problems of time-consuming and labor-intensive replacement, hinder the heat dissipation of nut components, etc., and achieve easy replacement and easy maintenance in good condition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

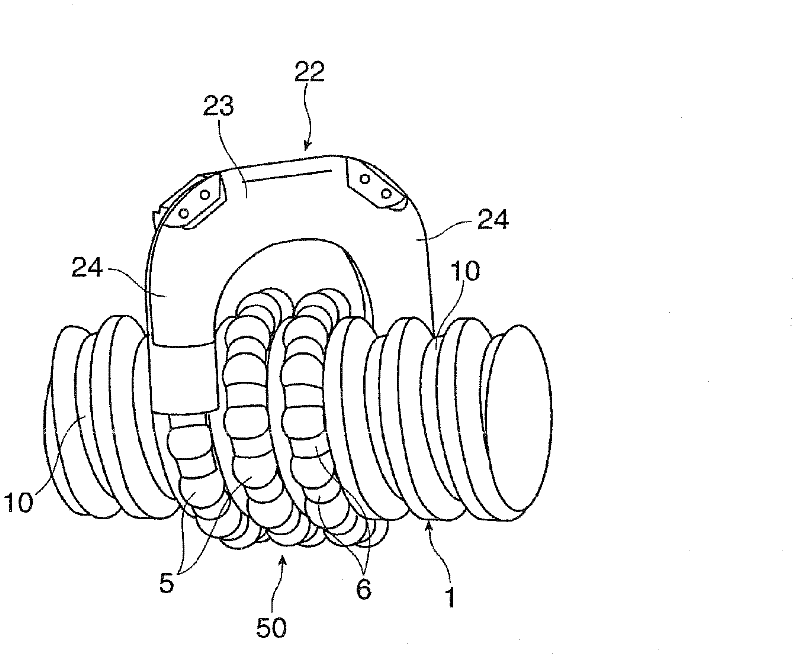

[0052] Hereinafter, the rolling element screw device of the present invention will be described in detail using the drawings.

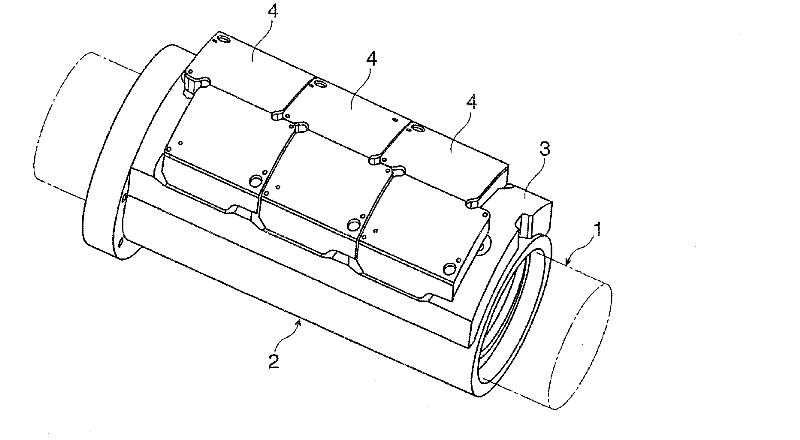

[0053] figure 1 It is an example showing that the present invention is applied to a ball screw device. This ball screw device includes: a screw shaft 1 in which rolling grooves for rolling balls as rolling elements are helically formed on an outer peripheral surface; a nut member 2 screwed to the screw shaft 1 by a plurality of balls; and A lubricant box 4 is mounted on the outer peripheral surface of the nut member 2 via a cover plate 3 . In addition, in figure 1 In , the above-mentioned screw shaft 1 is indicated by a dotted line.

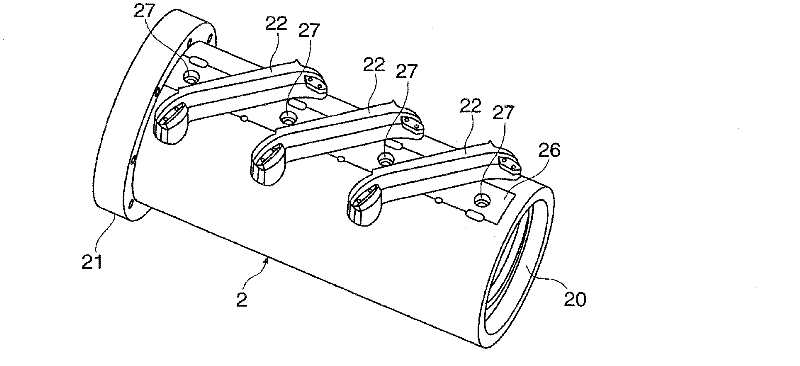

[0054] figure 2 It is a perspective view which shows the state which removed the said lubricant tank 4 and the cover plate 3 from the said nut member 2. The nut member 2 has a through hole 20 through which the screw shaft 1 is inserted, and is formed in a substantially cylindrical shape, and one end in the axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com