Air flow uniform distribution device for electric dust remover

A technology of uniform air distribution and electrostatic precipitator, applied in the field of electrostatic precipitator, can solve the problems of difficulty in ensuring uniform air distribution, difficulty in improving dust removal efficiency, increasing running resistance of dust collector and steel consumption, etc., to achieve steel consumption The effect of reduction, consumption reduction, and investment cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

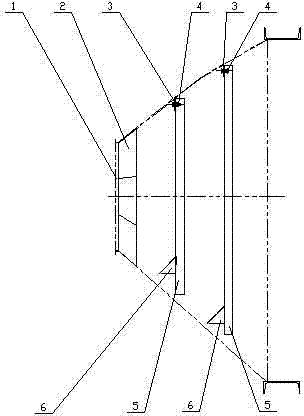

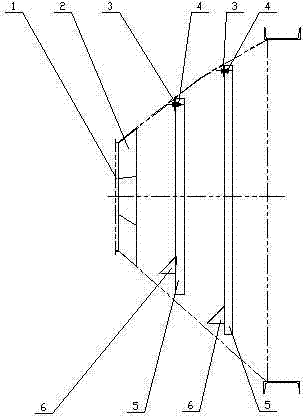

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] The present invention provides an airflow uniform distribution device for an electrostatic precipitator, which includes a deflector grid 2 , a hanging plate 3 , a bolt assembly 4 , a flow equalizer 5 and a triangular deflector 6 .

[0017] The periphery of the diversion grille 2 is welded to the inlet smoke box 1 and fixed;

[0018] The hanging plate 3 is welded to the upper sealing plate of the imported smoke box 1 and fixed, the equalizer plate 5 is fixed to the hanging plate 3 through the bolt assembly 4, and both sides of the equalizer plate 5 are welded and fixed to the side sealing plate of the imported smoke box 1;

[0019] The triangular deflector 6 is hung in the hole of the flow equalizer 5 , and the hanging plate is bent and welded with the flow equalizer 5 .

[0020] After the smoke enters the inlet smoke box 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com