Water curtain painting chamber

A spray booth and water curtain technology, applied in the field of water curtain spray booth, can solve the problems of high initial investment cost of air-conditioning equipment, large air-conditioning air supply volume, large heating power parameters, and energy waste, so as to reduce initial investment cost and reduce Energy consumption, reduced diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

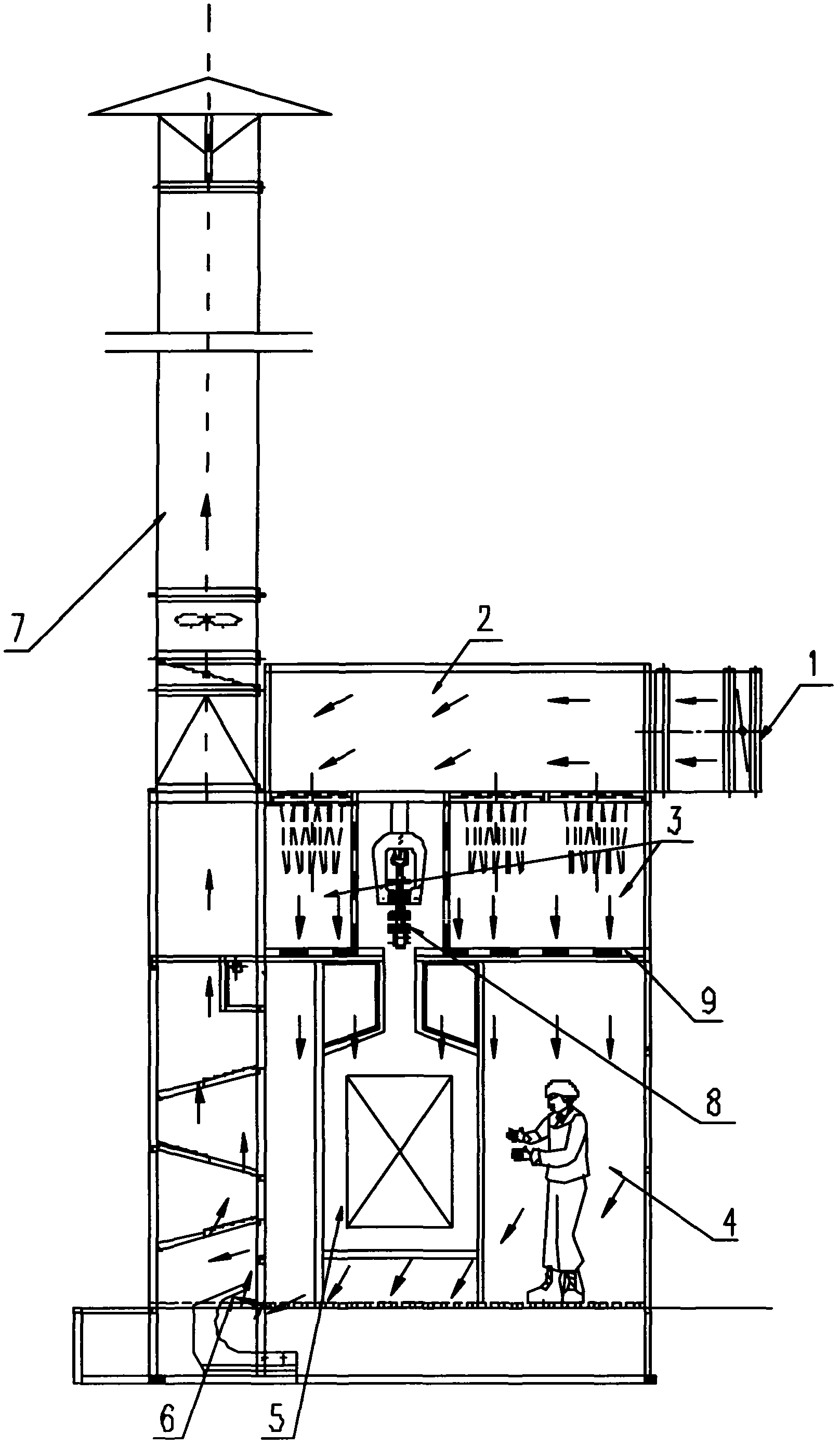

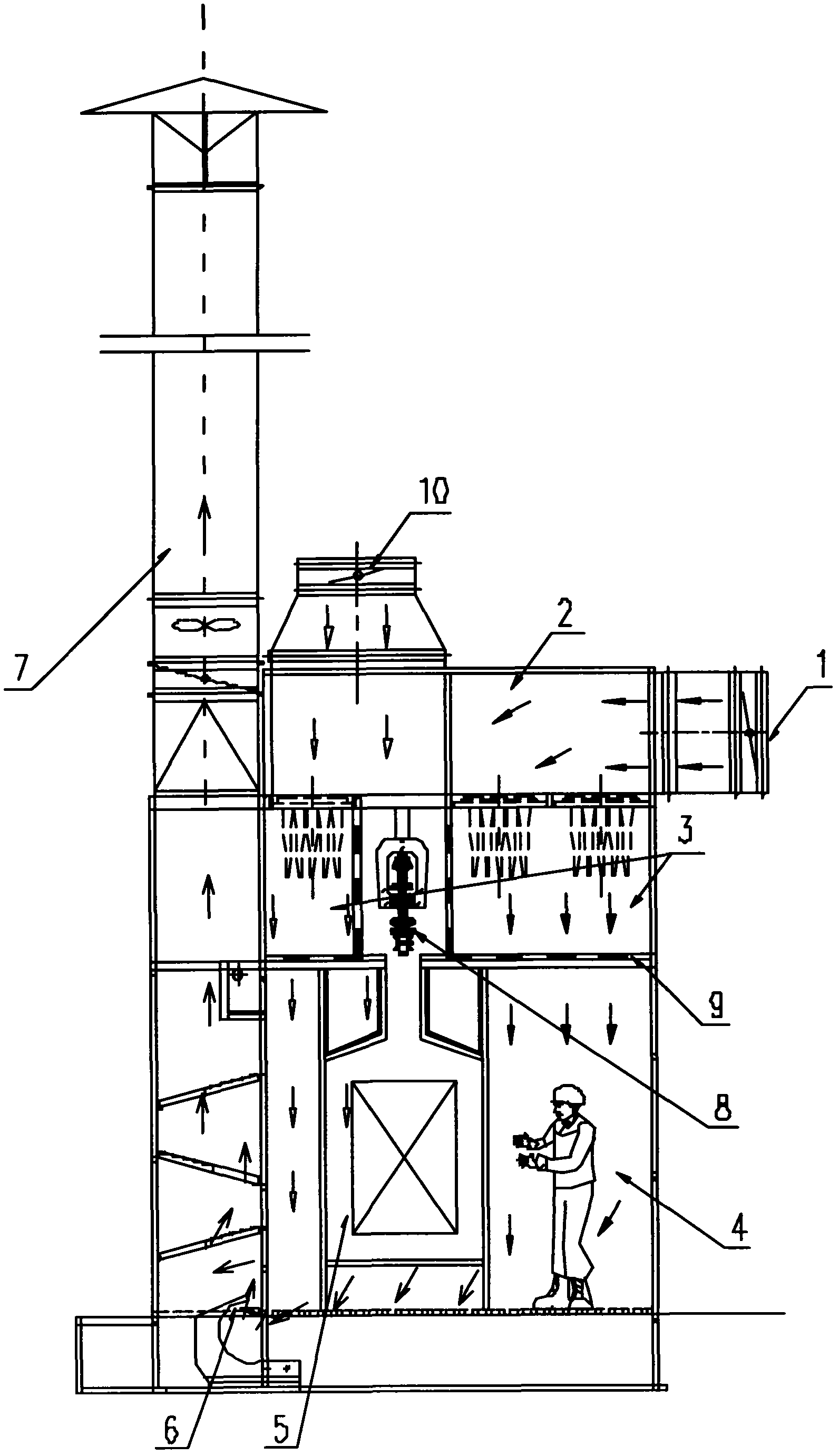

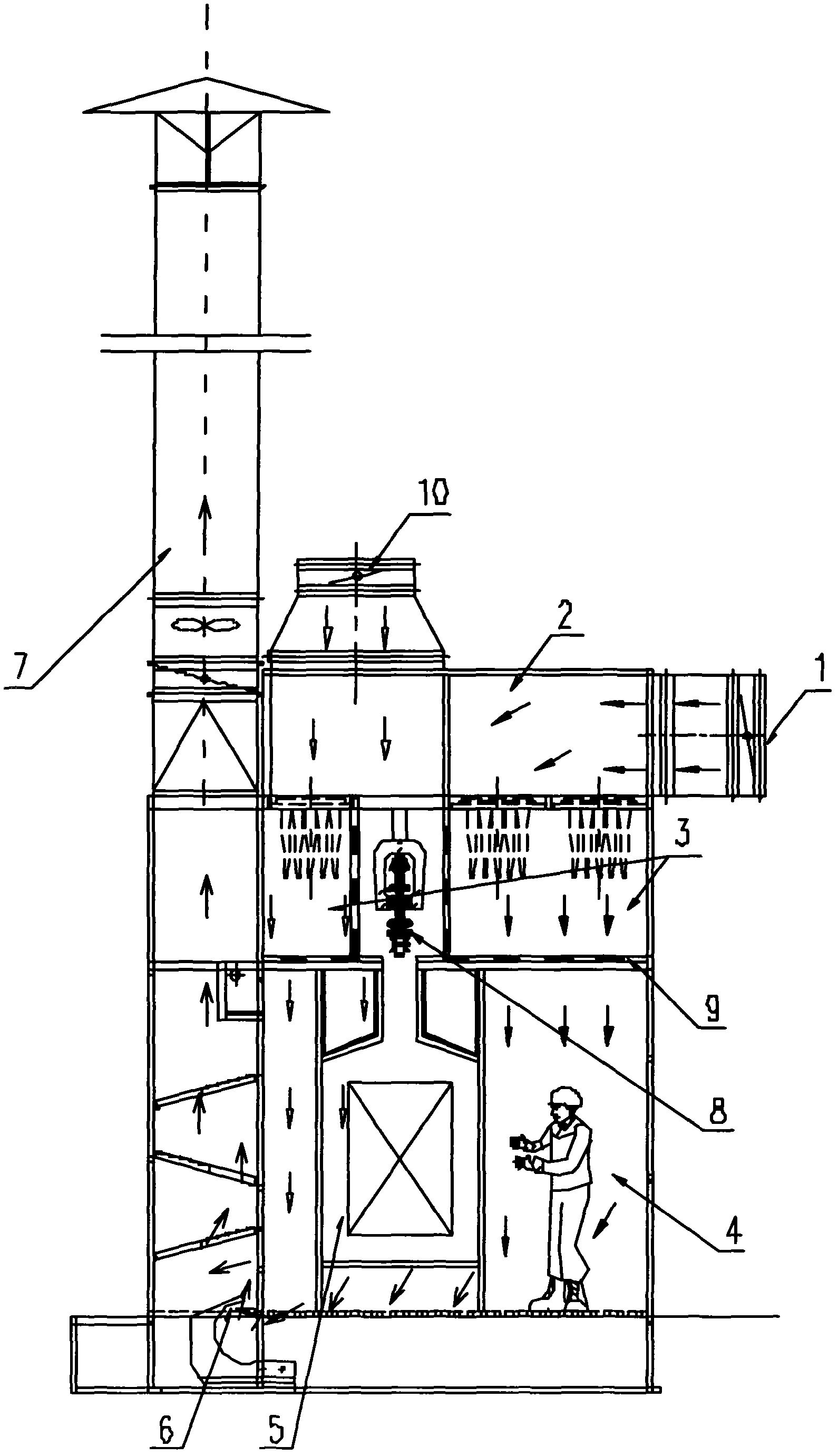

[0010] The water curtain spray booth is characterized in that it includes an air-conditioning air supply system 1, a natural air supply system 10, a manual work area 4, and a workpiece spraying area 5. The manual work area and the workpiece spraying area are independently supplied with air, and the air-conditioning air supply system Separated from the natural wind supply system, the air of the air conditioning supply system passes through the dynamic pressure chamber 2, the static pressure chamber 3, the manual work area 4, the paint mist treatment system 6, the exhaust system 7, and the natural wind supply system Pass through the dynamic pressure chamber, the static pressure chamber, the workpiece spraying area 5, the paint mist treatment system, and the exhaust system in sequence.

[0011] The water curtain spray booth of the present application adopts air-conditioning air supply for the manual work area, and natural wind after filtering is used for the workpiece spraying are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com