Mesoporous silica resin and preparation method thereof

A technology of mesoporous silicon and resin is applied in the field of mesoporous silicon resin and its preparation, and achieves the effects of low glass transition temperature, environmental friendliness and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

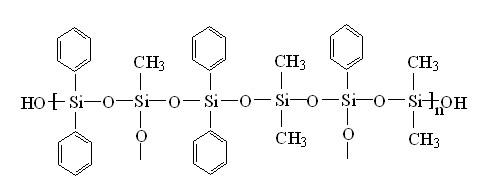

[0037] Example 1 Preparation of methylphenylsilane (MPS) resin solution

[0038] Put a 250ml four-necked flask equipped with a stirrer, dropping funnel, reflux condenser and thermometer in a water bath, add 100g of water and 65g of tetrahydrofuran into the four-necked flask, and stir well; add 8g of Ph 2 SiCl 2 , 18g PhSiCl 3 , 9g (CH 3 ) 2 SiCl 2 , 15g (CH 3 ) SiCl 3 , Mix these monomers evenly; raise the temperature of the four-necked flask to 50°C, start adding the mixture of monomers dropwise, control the temperature between 50~70°C, and complete the dropwise addition in 1 hour; continue stirring after the dropwise addition 30min; Pour the reaction product into a separatory funnel, let stand to separate the water layer, wash the solvent layer with 60°C distilled water for 4 times, and then neutralize the solvent layer with 0.01~0.05ml of NaOH with a concentration of 20~40wt% until neutral to obtain Prepolymer of silicone resin; vacuum distillation of silicone re...

Embodiment 2

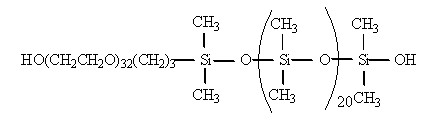

[0039] Example 2 Preparation of Mesoporous Silicone Materials

[0040] By solvent evaporation-induced self-assembly (EISA) method, methylphenylsiloxane (MPS) was used as the resin matrix, and PDMS-PEO diblock copolymer was used as the template to synthesize the mesoporous silicone resin material. The steps were as follows: 1.0 g The PDMS-PEO block copolymer was dissolved in 20.0 g tetrahydrofuran (THF) solvent and stirred at 30-50 °C for 10 min to obtain a clear solution. A THF solution of 10.0 g of 30 wt % MPS resin was added. Continue stirring for 0.3–0.6 h, and transfer the mixture to a Petri dish. Volatilize at room temperature for 5-8 h to remove THF, and then thermally polymerize in an oven at 150 °C for 20-24 h. The product obtained was a pale yellow transparent layer or film material which was scraped off the evaporating dish and ground to a powder. The mesoporous silicone resin material was obtained by firing in a tube furnace at 300°C for 3-5 h under a nitrogen ...

Embodiment 3

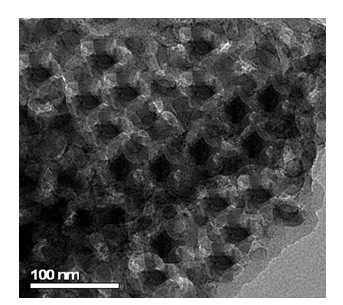

[0041] Example 3 The structure of the obtained material was characterized by JEOL JEM2011 high-resolution transmission electron microscope (TEM) at an accelerating voltage of 200 kV. The sample preparation process is as follows: the powdered material is dissolved in ethanol to form a slurry state, and the slurry is hung on a copper net with a carbon film, and can be directly used for observation after drying. The TEM image of the obtained mesoporous silicone resin material is as follows image 3 shown. Depend on image 3 It can be seen that the average pore size of the obtained material is 25nm. It shows that the silicone resin material with a porous structure can be produced by using the PDMS-PEO block copolymer as a template.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com