Liquid photoreceptive solder resist ink

A photosensitive solder resist ink, liquid technology, applied in the direction of ink, optics, optomechanical equipment, etc., can solve the problems of sinking tin easy to lose oil, poor solder resist performance, poor chemical resistance, etc., to achieve high resolution, high waterproof , the effect of high insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

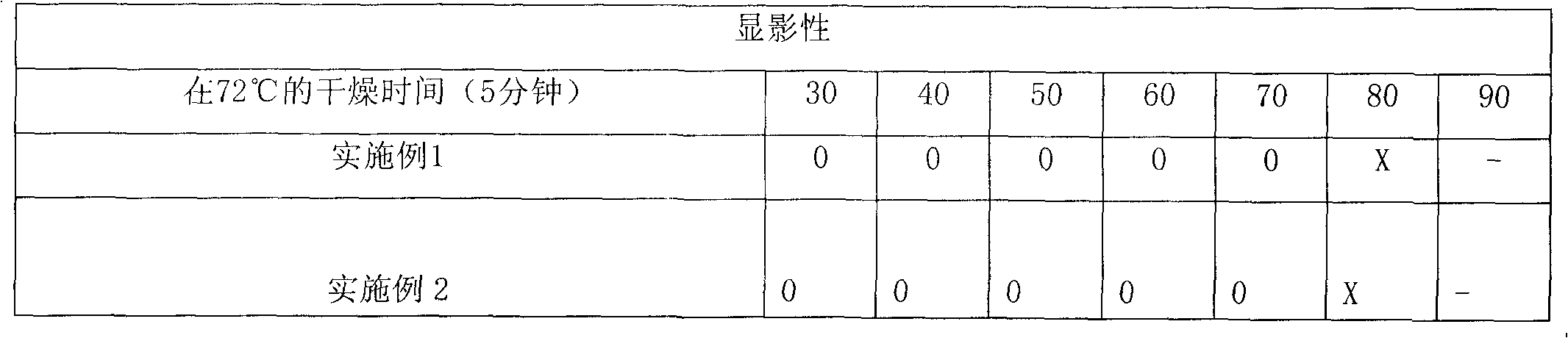

Examples

Embodiment Construction

[0013] The liquid photosensitive solder resist ink according to the embodiment of the present invention is mainly composed of a main agent and a curing agent in a 3:1 combination.

[0014] The main agent is mainly composed of photosensitive resin, phthalocyanine green, melamine, photoinitiator, photosensitizer, dispersant, tetramethylbenzene, leveling agent, dibasic acid ester solvent, and barium sulfate.

[0015] The preparation method of the photosensitive resin is: adding 210 parts of o-cresol novolac epoxy resin (epoxy equivalent 210) into the reaction kettle, adding 100 parts of DBE (Oumod), and heating and dissolving. Next, add 0.1 part of the polymerization inhibitor p-hydroxyanisole and 1.5 parts of the catalyst triphenylphosphorus, heat the mixture to 95-105°C, slowly drip in 72 parts of acrylic acid, allow the reaction for 6 hours, and cool the reactant To 90℃, add 101 parts of tetrahydrophthalic anhydride, 110 parts of tetratoluene, 48 parts of DBE, keep at 90-95℃ and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com