Method for estimating performance of additive for limestone wet-method flue gas desulfurization

A technology of wet flue gas desulfurization and evaluation methods, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large amount of chemical consumption, incompleteness, and unsystematic, and achieve shortened evaluation time, reduced chemical consumption, and accurate Evaluation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

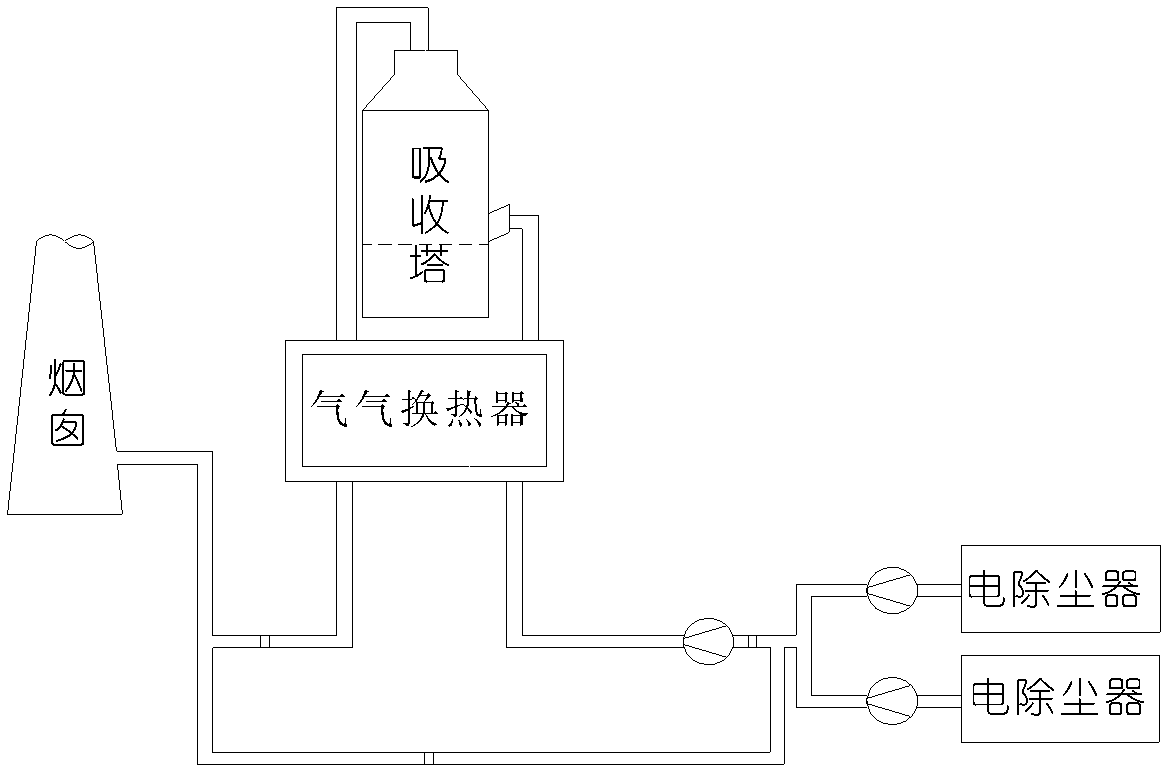

[0024] The performance evaluation method of limestone wet desulfurization additive, the steps are as follows:

[0025] (1) According to the desulfurization system used and the desulfurization additives to be evaluated, select the operating conditions required for evaluation;

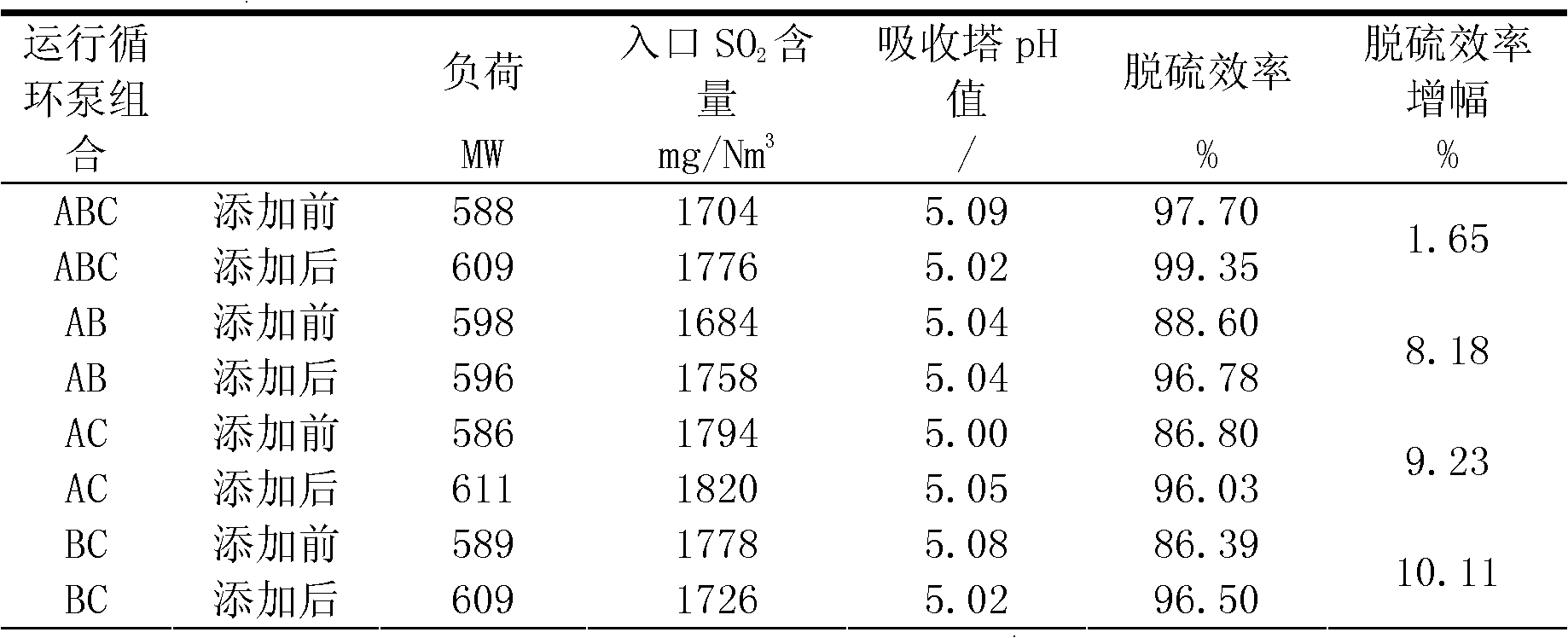

[0026] (2) Operate according to the selected operating conditions, and calculate various parameters such as desulfurization efficiency before and after the addition of additives in each operating condition. During the process, it is necessary to ensure the accuracy and comprehensiveness of the data statistics and the matching degree of the operating conditions before and after the addition of additives;

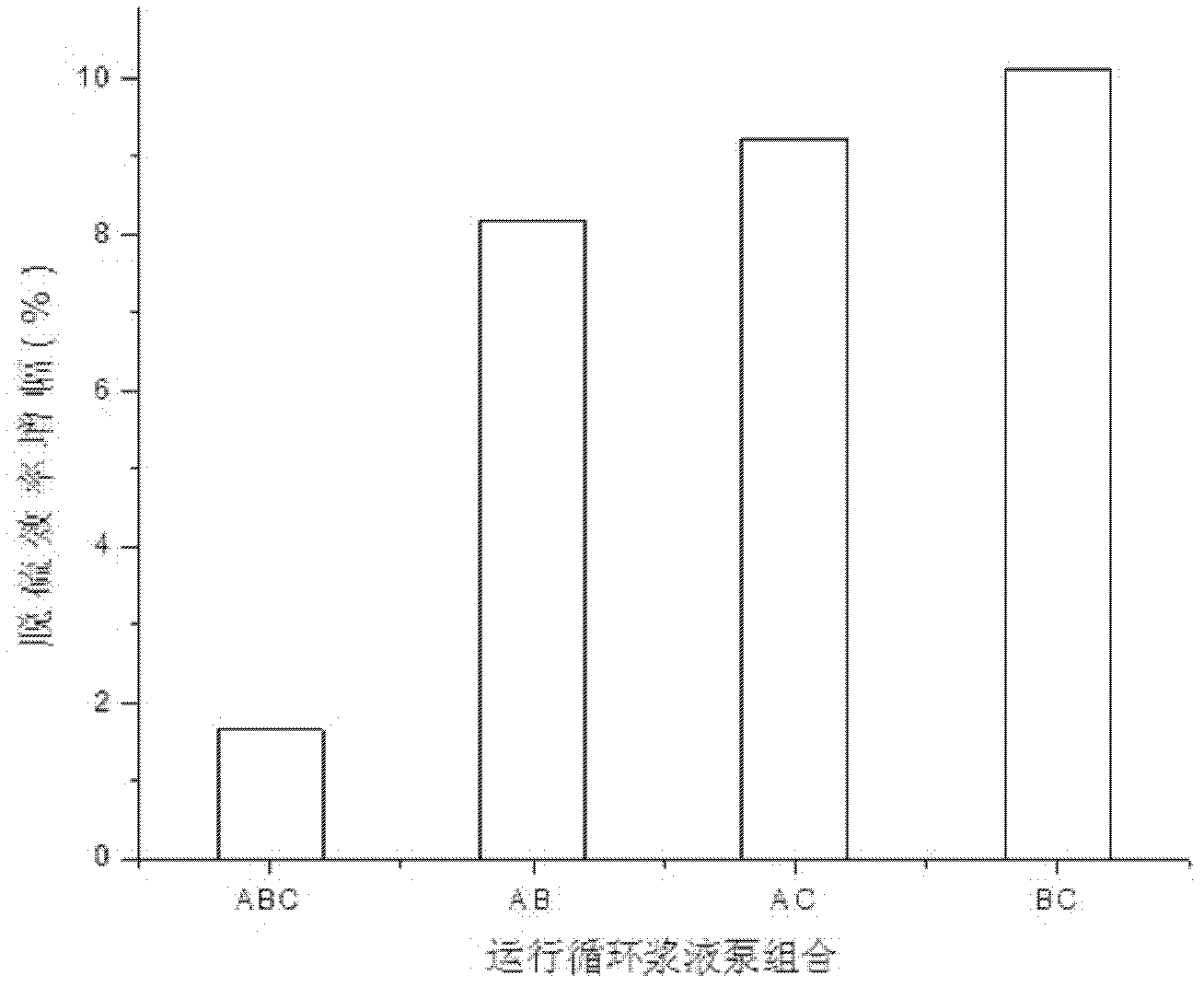

[0027] (3) Evaluate the effect of additives on the desulfurization effect by using the desulfurization efficiency of each working condition after the addition of additives is increased relative to the desulfurization efficiency without adding them, and at the same time use indicators such as gypsum quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com