Isolated insulation cover and isolating switch device

A technology of isolating switch and insulating cover, which is applied in the direction of switchgear, setting of switchgear, electric switch, etc., can solve the problems of large insulation distance, large occupied body, large volume of metal box, etc., and achieve volume reduction, cost saving, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

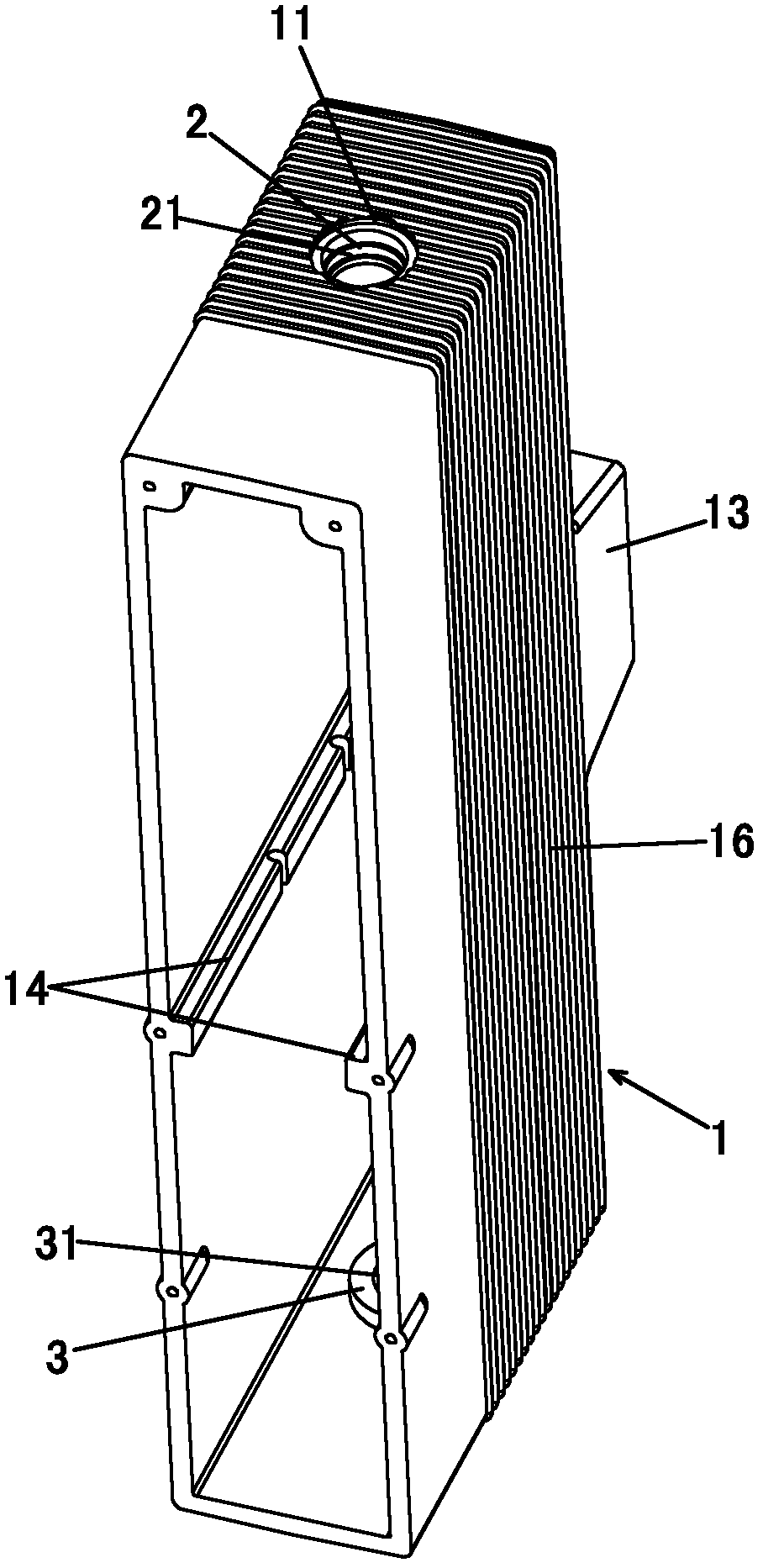

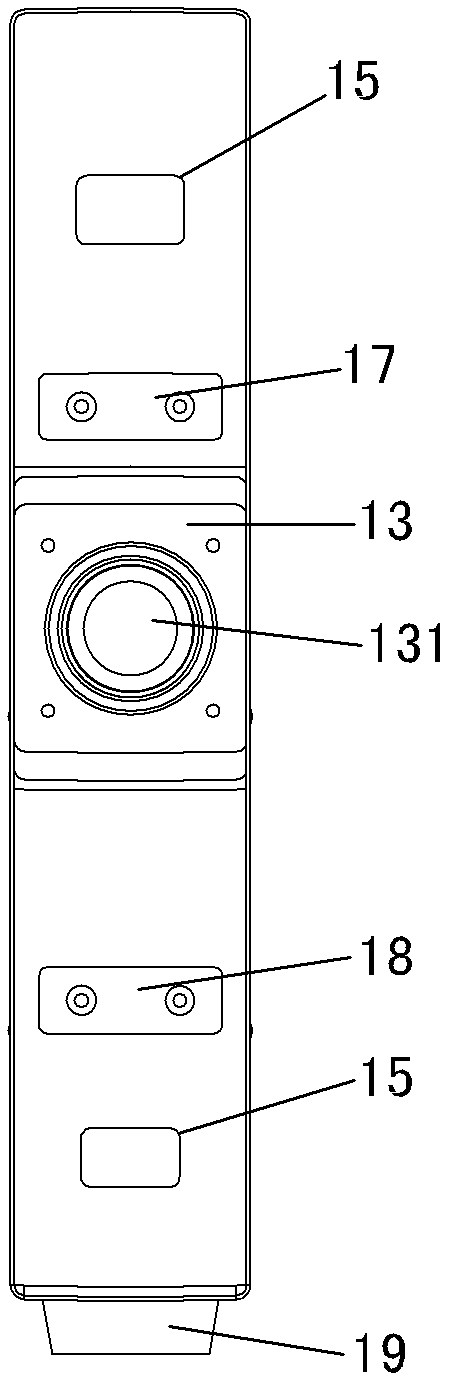

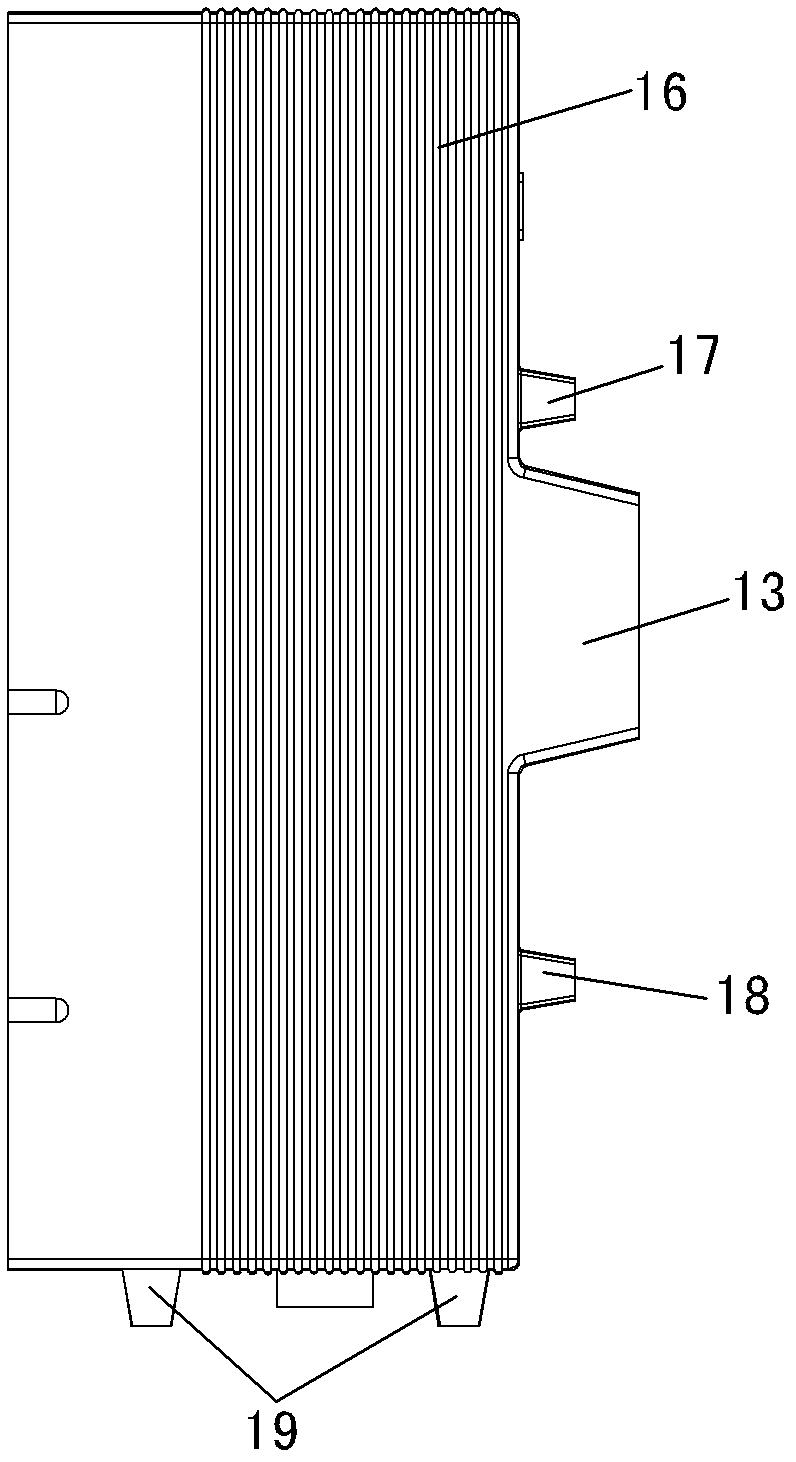

[0023] see Figure 1 to Figure 4 and Figure 7 As shown, the isolation and insulation cover of the present invention includes a cuboid cover body 1 with an open rear made of solid insulating material epoxy resin, and a rear plate can also be installed at the rear open position of the cover body 1 as required. Generally, the situation where the back plate is installed is mostly a place with a harsh environment, and the addition of the back plate can prevent the oxidation of each part of the switch isolation unit in the inner cavity of the cover body 1 . Here we only introduce the usage without a rear panel in a normal environment. The upper plate of the cover body 1 is processed with a tapered upper and lower two-section first stepped hole 11, and a first insulating sleeve 2 is installed in the upper cavity of the first stepped hole 11, and a second insulating sleeve 2 is processed on the first insulating sleeve 2. Stepped hole 21, the lower plate of the cover body 1 is proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com