Voltage conversion circuit for forward design of auxiliary winding in flyback topology

A technology of voltage conversion circuit and auxiliary winding, which is applied in the direction of adjusting electric variable, output power conversion device, converting DC power input to DC power output, etc. Problems such as more stable control signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

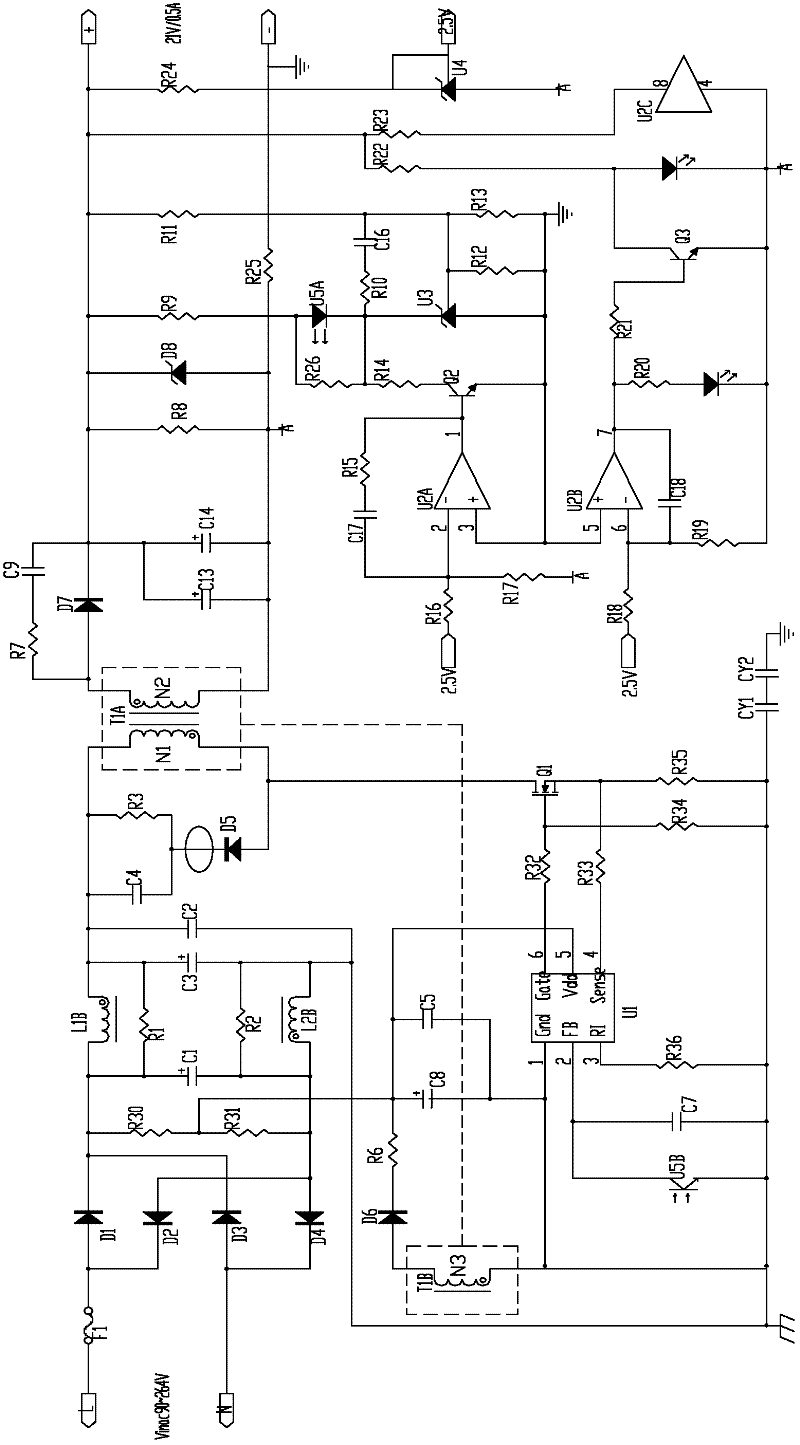

[0020] In the following, the voltage conversion circuit of the auxiliary winding forward design in the flyback topology of the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods, so as to understand the technical idea claimed by the present invention more clearly.

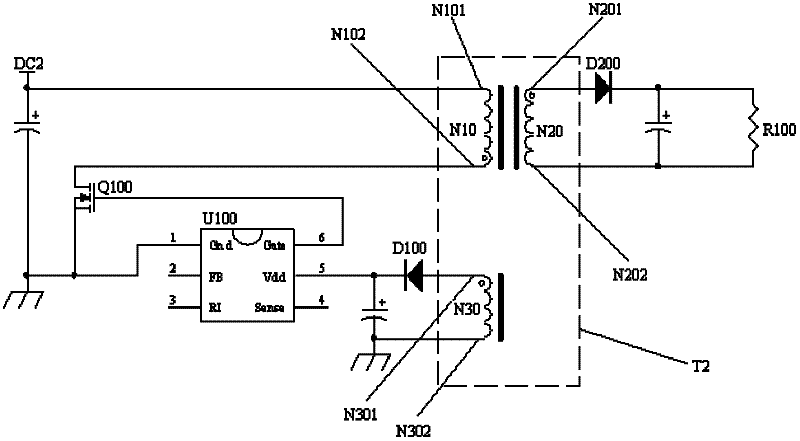

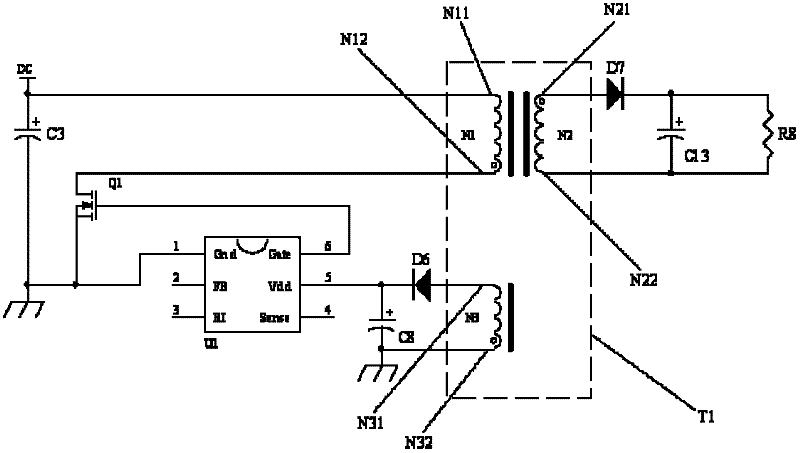

[0021] Such as figure 2 As shown, the voltage conversion circuit of the auxiliary winding forward design in the flyback topology includes the voltage input terminal DC, the transformer T1, the switch tube Q1, the pulse generator U1, the first diode D6, the second diode D7, the load R8, first capacitor C13, second capacitor C8, transformer T1 includes primary winding N1, auxiliary winding N3 and secondary winding N2, primary winding N1 includes first end N11 and second end N12, auxiliary winding N3 includes third end N31 and the fourth terminal N32, the secondary winding N2 includes a fifth terminal N21 and a sixth terminal N22, the voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com