Method for sorting potato products and sorting apparatus for potato products

A potato and product technology, used in sorting, material inspection, testing food, etc., can solve problems such as potato product defects that cannot be detected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

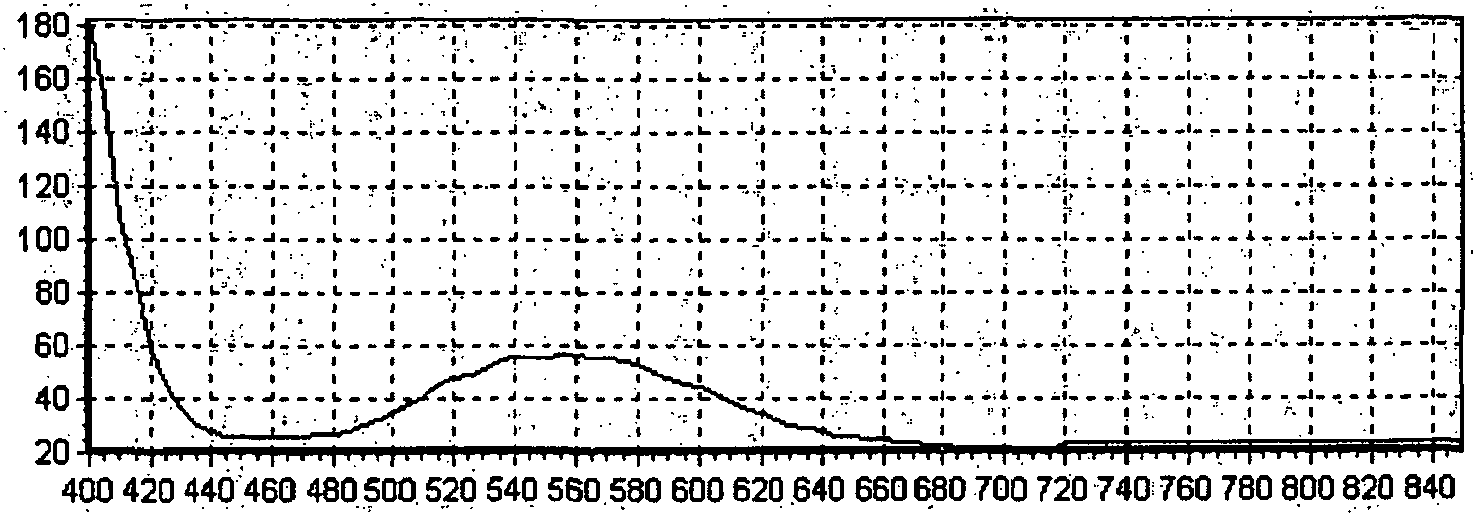

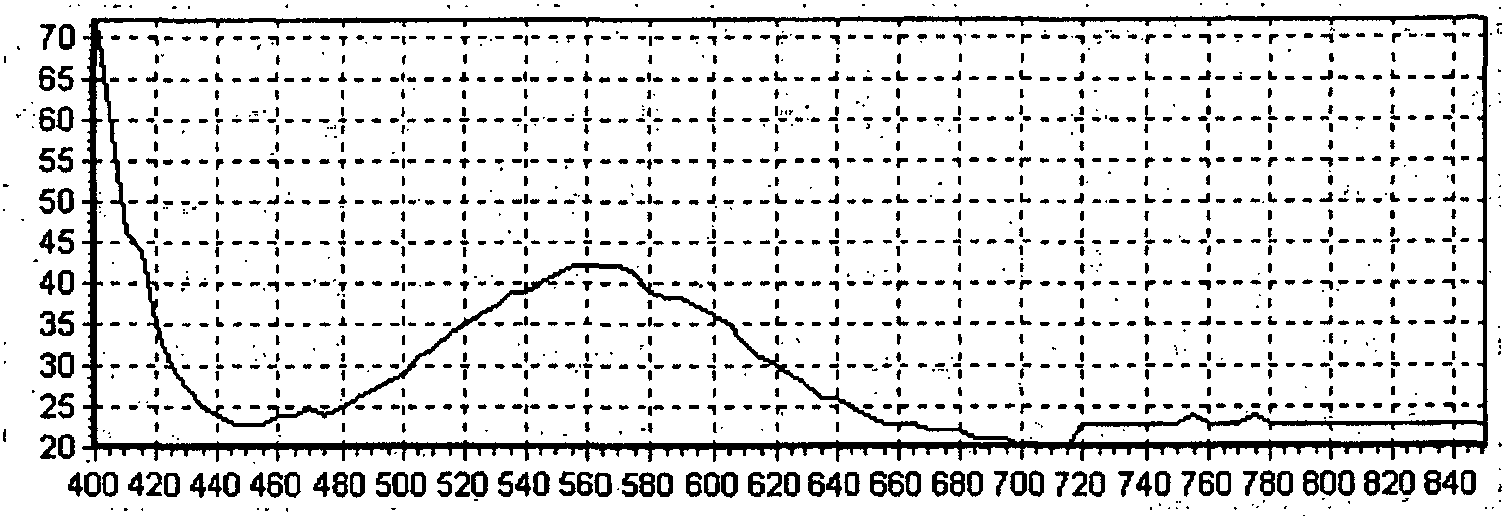

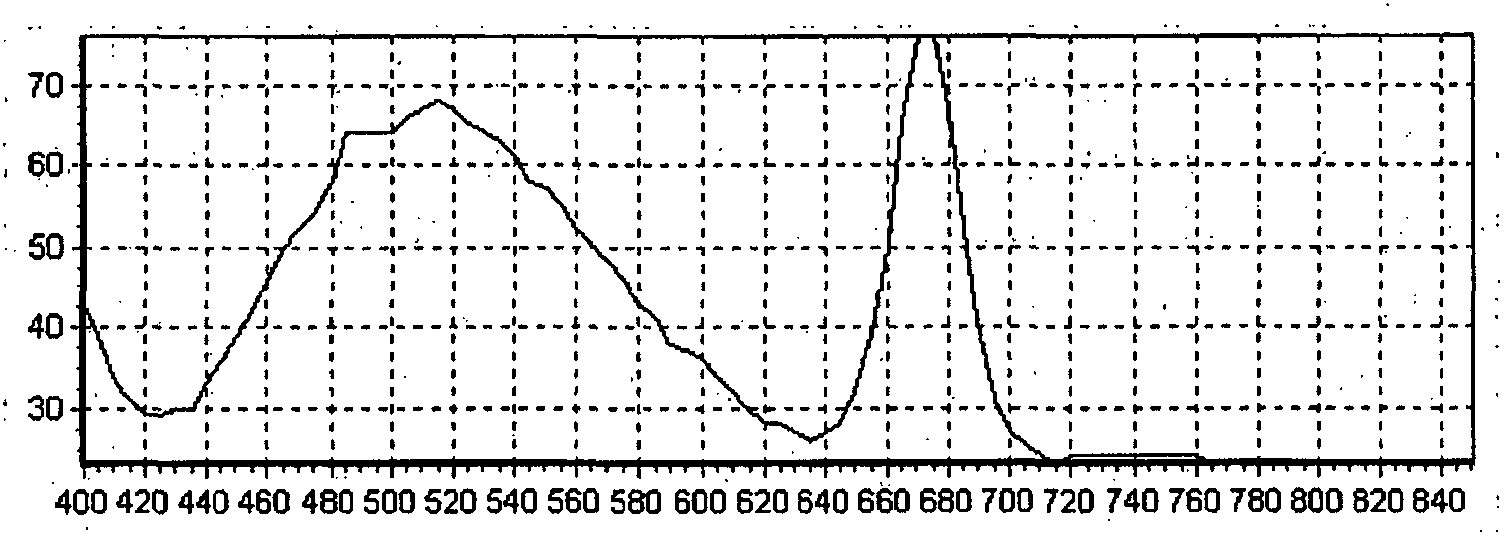

[0028] In the method according to the invention, the potato products are sorted based on fluorescence. It was found that when UV light with a wavelength of 350nm-450nm is shone on the potato product, a potato product without any defects will emit light as a result of fluorescence with a wavelength mainly in the wavelength band of 460nm-600nm. Defects present in the potato product or odd products in the product stream do not have said fluorescence. Defects are usually visually observable and include, for example, bud eyes, side shoots or buds, rot, abrasions, internal sugars, brown vascular rings, and the like.

[0029] According to the invention, a product stream of potato products moves through a detection zone where the products are illuminated by UV light. The intensity of light emitted by the product as a result of fluorescence is detected in the detection band from 460nm to 600nm. When the observed intensity in the detection zone is lower than a specific preset value fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com