Mussel silking machine

A silk machine and mussel technology, which is applied in the field of mussel desilvering machines to achieve the effects of reducing pollution and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

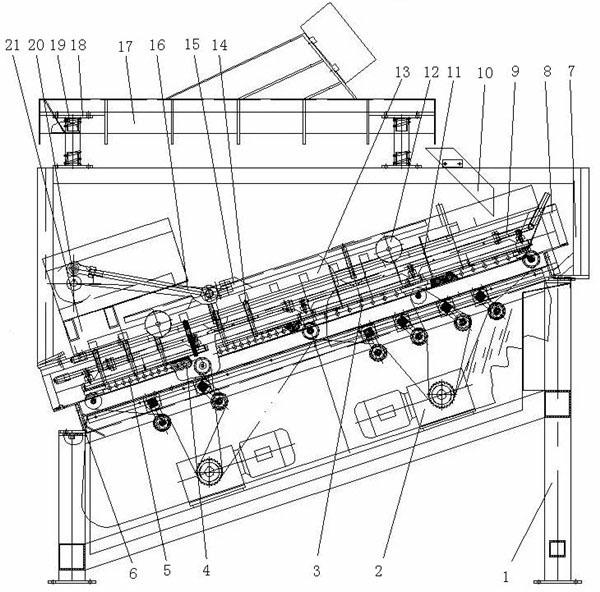

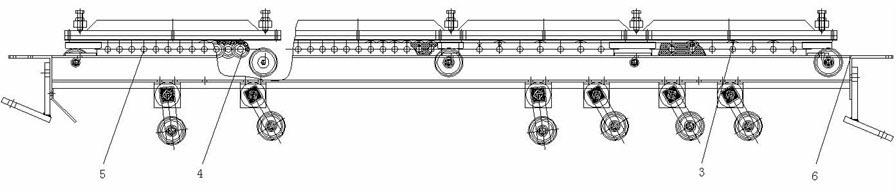

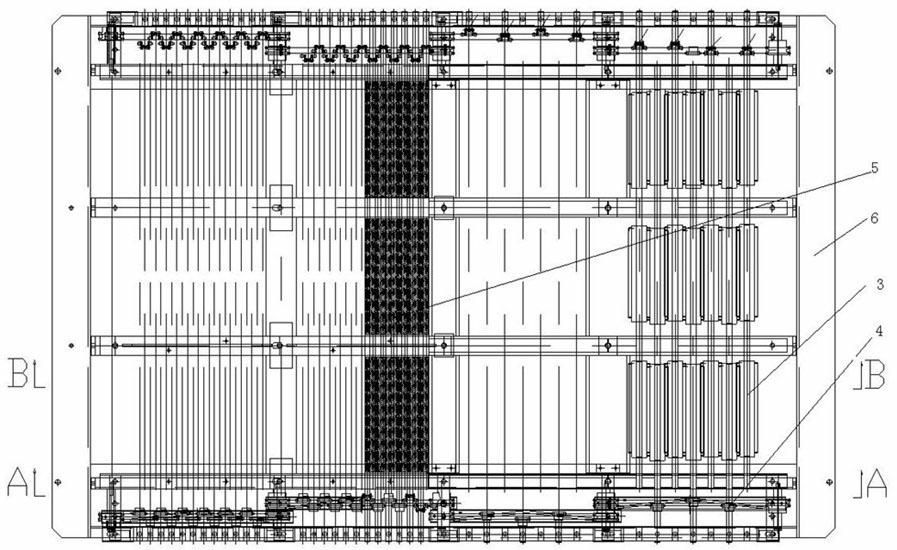

[0022] Such as Figure 1-9 As shown, the present invention comprises a feeding device, an even material device, a wire removal device and an underframe 1, the feeding device includes a vibrating hopper 17, a vibrating hopper support 7, a hopper 10, and a vibrating motor is installed on the vibrating hopper 17 , the bottom of the vibrating hopper 17 and the top of the vibrating hopper bracket 7 are correspondingly equipped with a spring seat 18, and the two are connected by a spring 19 to achieve the effect of vibrating feeding. One end of the vibrating hopper 17 is provided with a hopper 10, so The hopper 10 communicates with the wire removal device, and the wire removal device includes a frame 6, a brush group, and a steel rod group, and the brush group and the steel rod group are sequentially installed on the frame 6 along the feeding direction. The brush 3 is connected by a sprocket 4, and the steel rod group is formed by connecting a plurality of embossed steel rods 5 by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com