Intelligent anti-blocking demister used for wet flue gas desulfurization

A technology of wet flue gas desulfurization and mist eliminator, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve problems such as flow blockage, shutdown, and difficulty in timely detection of blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in further detail below, but the embodiments of the present invention are not limited thereto.

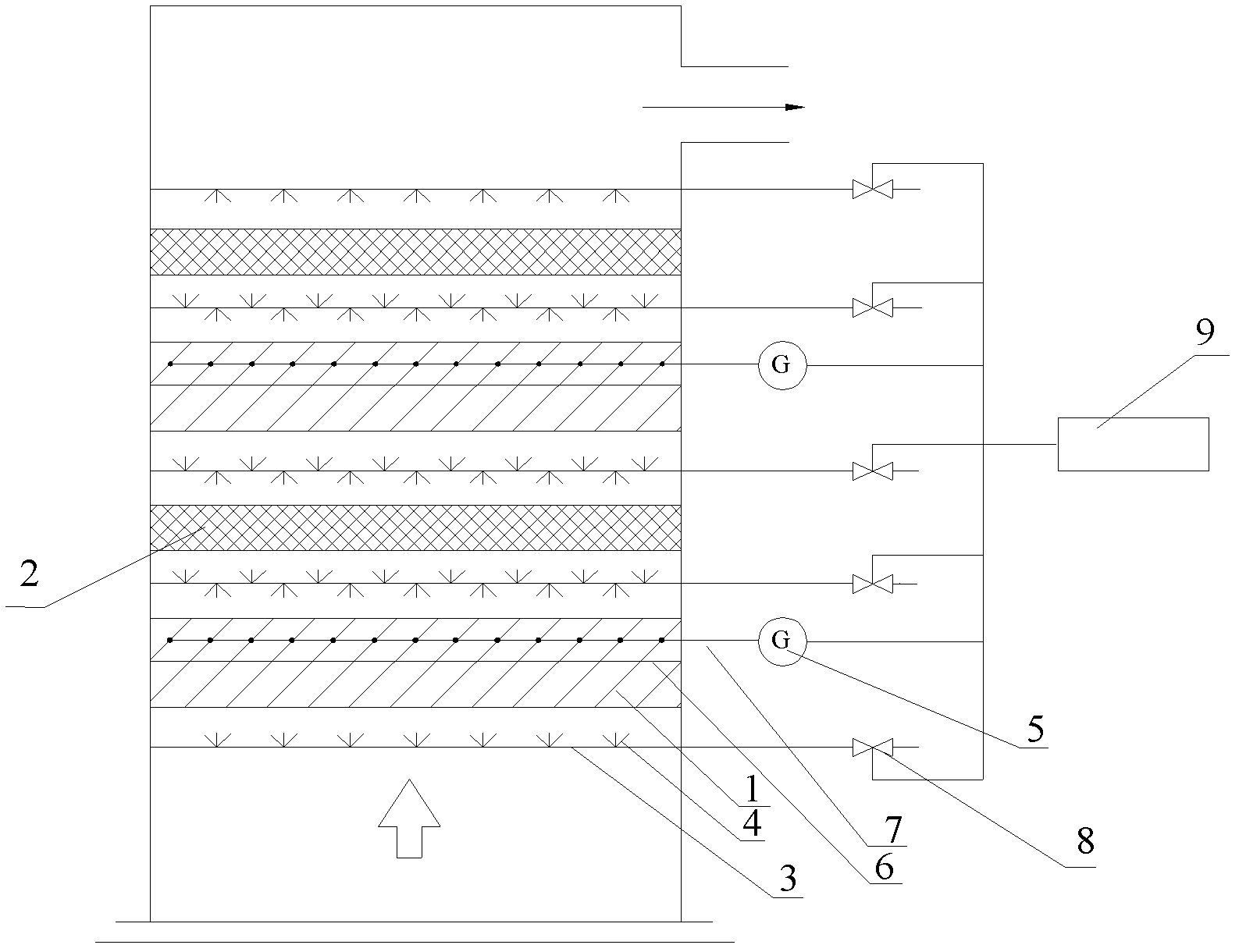

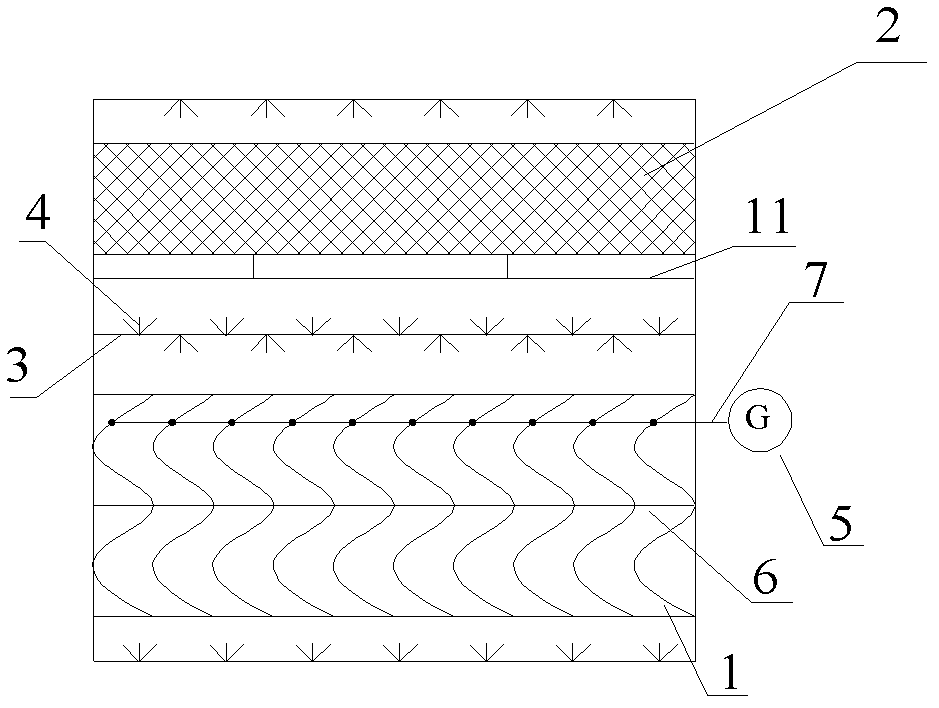

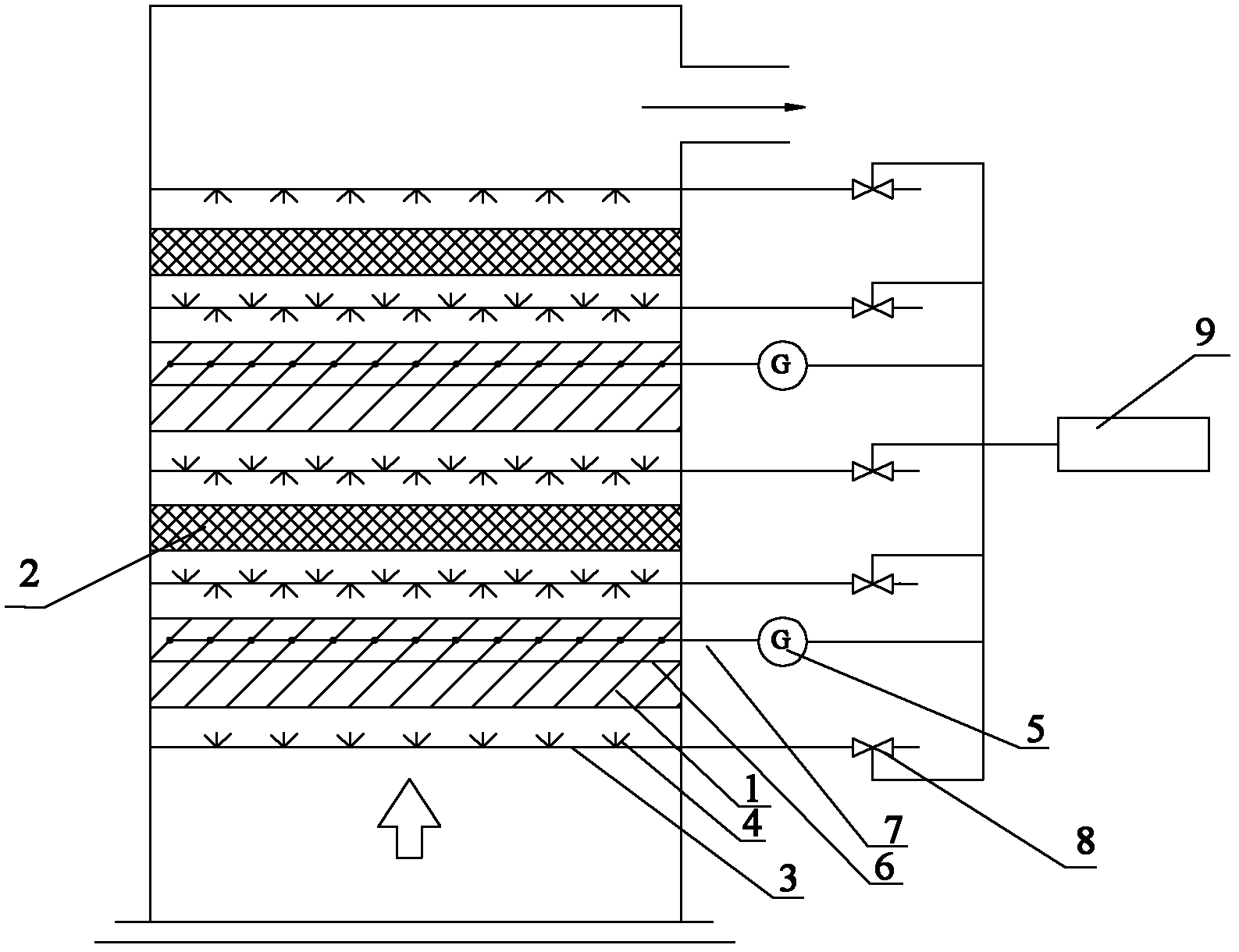

[0022] like figure 1 shown. The anti-blocking demister for wet flue gas desulfurization of the present invention includes a demister body, at least one stage of demisting system is arranged in the demister body, and the demistering system is connected with a PLC control system, and each stage The defogging system includes the first flushing layer, the swing baffle defogging layer, the second flushing layer, the wire mesh defogging layer, and the third flushing layer arranged in sequence from bottom to top.

[0023] The first flushing layer includes nozzles 4 arrayed on the flushing water pipe 3, and the spraying direction of the nozzles 4 corresponds to the defogging layer of the swing baffle. The nozzle 4 adopts a high-pressure flushing water nozzle.

[0024] The defogging layer of the swing-type baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com