Garbage incinerator

A waste incinerator and furnace body technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems affecting equipment use space, equipment scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

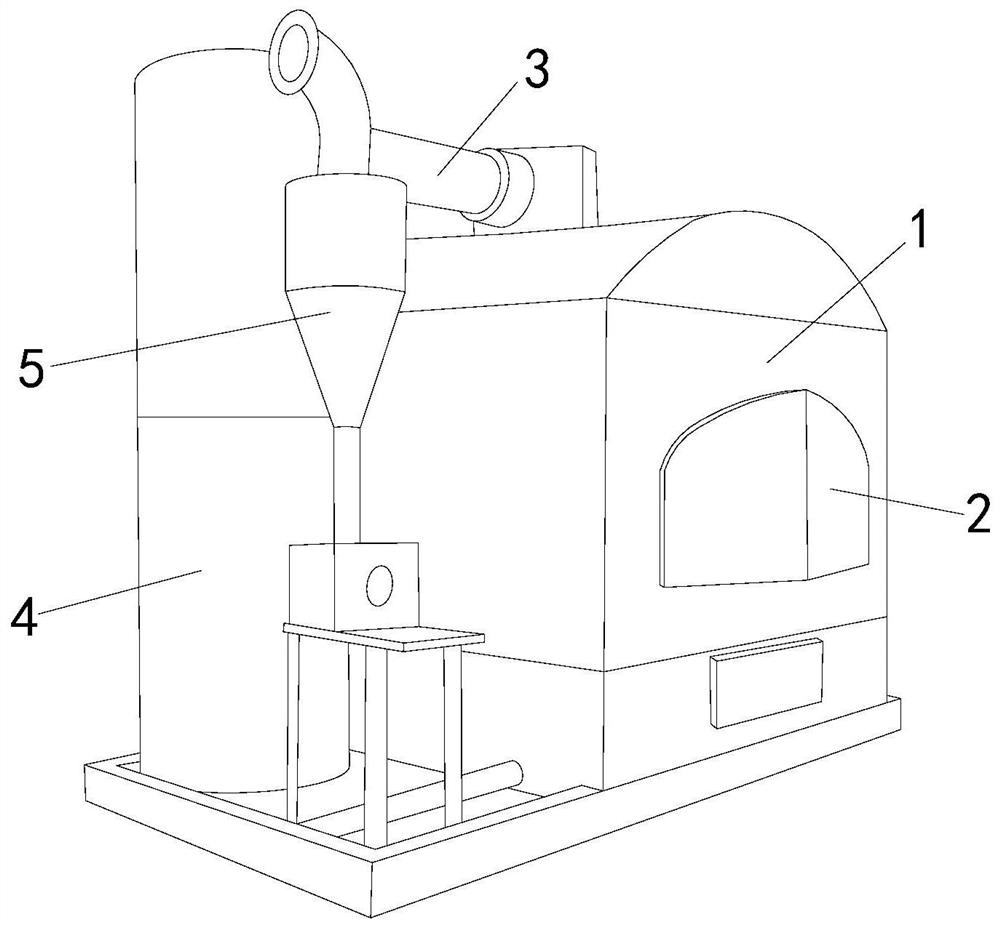

[0024] see figure 1 , the present invention provides a garbage incinerator, the structure of which includes: a furnace body 1, a delivery bin 2, a flue 3, a combustion tower 4, and a purification tower 5, the front of the furnace body 1 is provided with a delivery bin 2 and its top is connected to The flue 3 and the flue 3 are respectively connected to the combustion tower 4 and the purification tower 5. The furnace body 1 has an irregular box structure as a whole, and its interior is hollow and can be used for putting in garbage for incineration. It is used to connect other components to make them mutually The connected frame carrier is also the core incineration component of the equipment. The delivery bin 2 is a hatch structure, which is used as an input port for garbage raw materials after opening. It relies on strong sealing performance to isolate the heat assimilation and transfer inside and outside the equipment, and It can effectively prevent the high temperature and ...

Embodiment 2

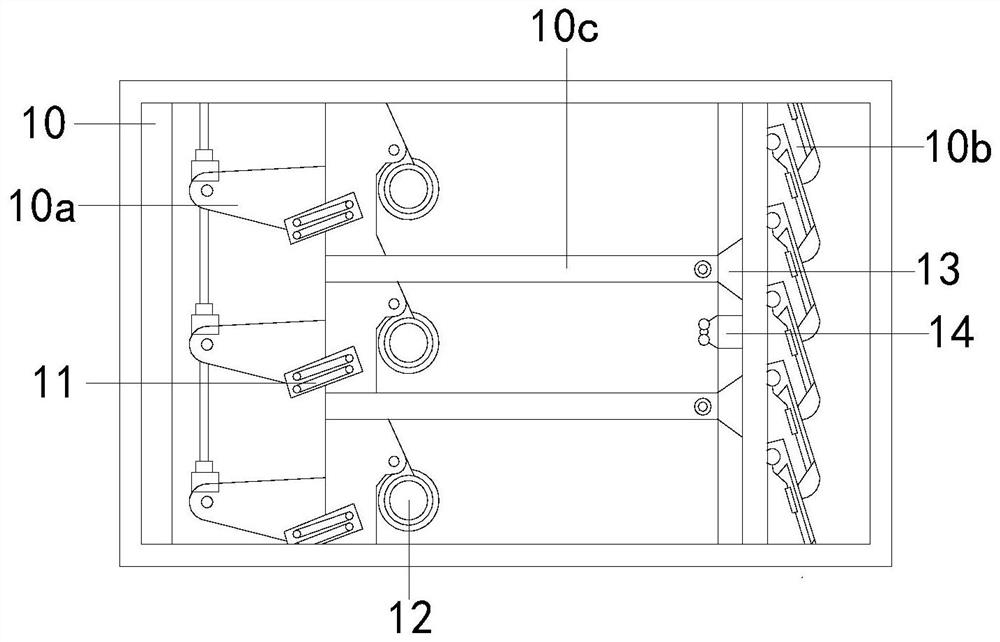

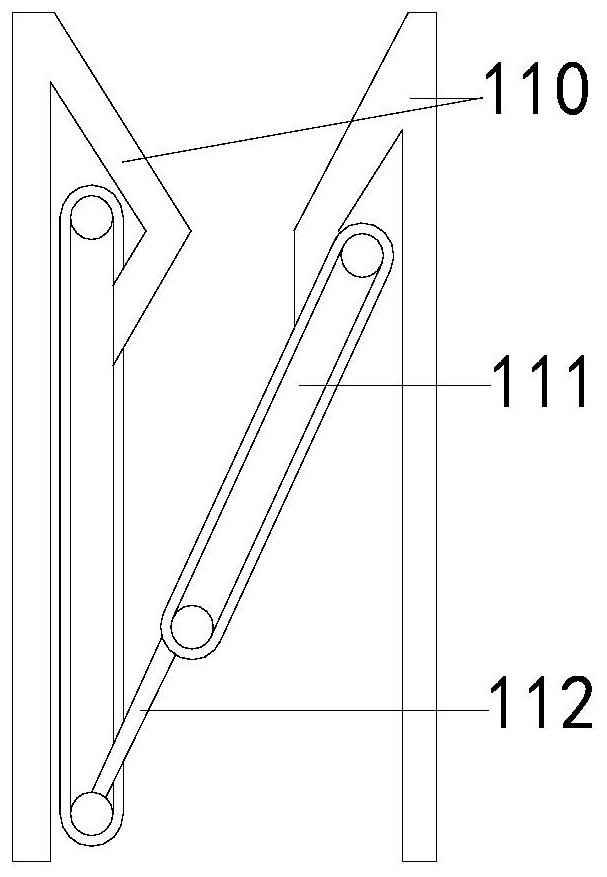

[0031] The description of the second embodiment drawn in conjunction with the first embodiment, combined with figure 2 , Figure 4 and Figure 6 , the furnace frame 10 is connected with a stretching plate 11 and is provided with a crushing wheel 12, an overturning shaft 13 and a grinding wheel 14 at the same time. 122, the two sides of the positioning wheel 140 are provided with side cutting wheels 141 at intervals, and the side cutting wheels 141 are connected by swing rods 142 and simultaneously fitted with ring cutting rings 143. The high-temperature firepower produced by the guide chain grate 10b concentrates on the grid 10c and waits for the garbage to be melted. At this time, part of the garbage cannot be fully burned and melted. The kinetic energy of rotation produces a bite action on the surface of the grid 10c to tear off the solidified matter that cannot be erased by the high-speed wheel 122 from the grid 10c, and the side cutting wheel 141 scrapes off the solidif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com