Simulation experiment device in petrochemical apparatus during emergent relief process

A simulation experiment device, petrochemical technology, applied in chemical/physical process, chemical/physical/physical-chemical process, method of chemically changing substances by using atmospheric pressure, etc. Unable to release the whole process simulation, single experimental function and other problems, to achieve the effect of adiabatic heat test, novel structure design, and large dose of reactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

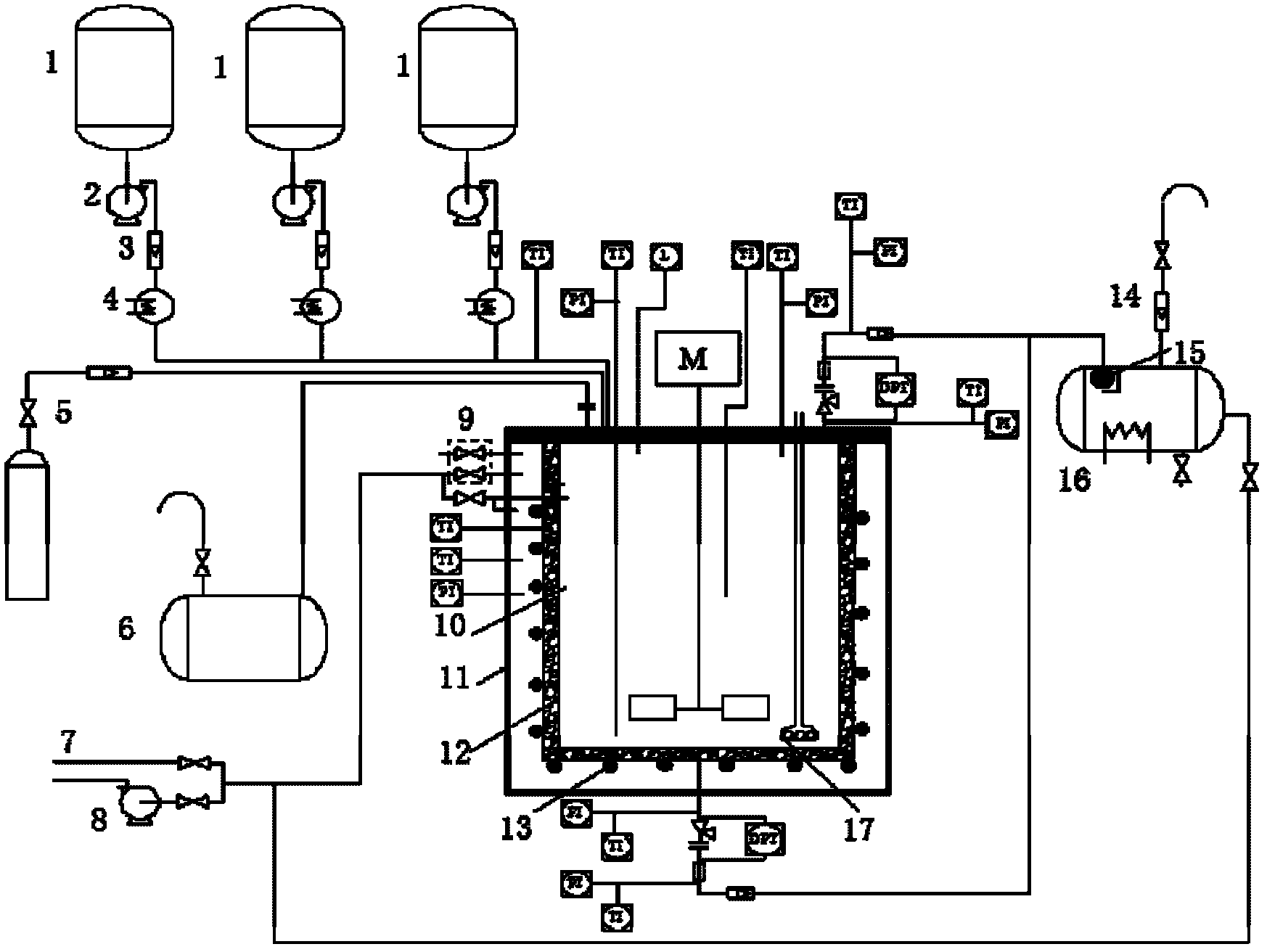

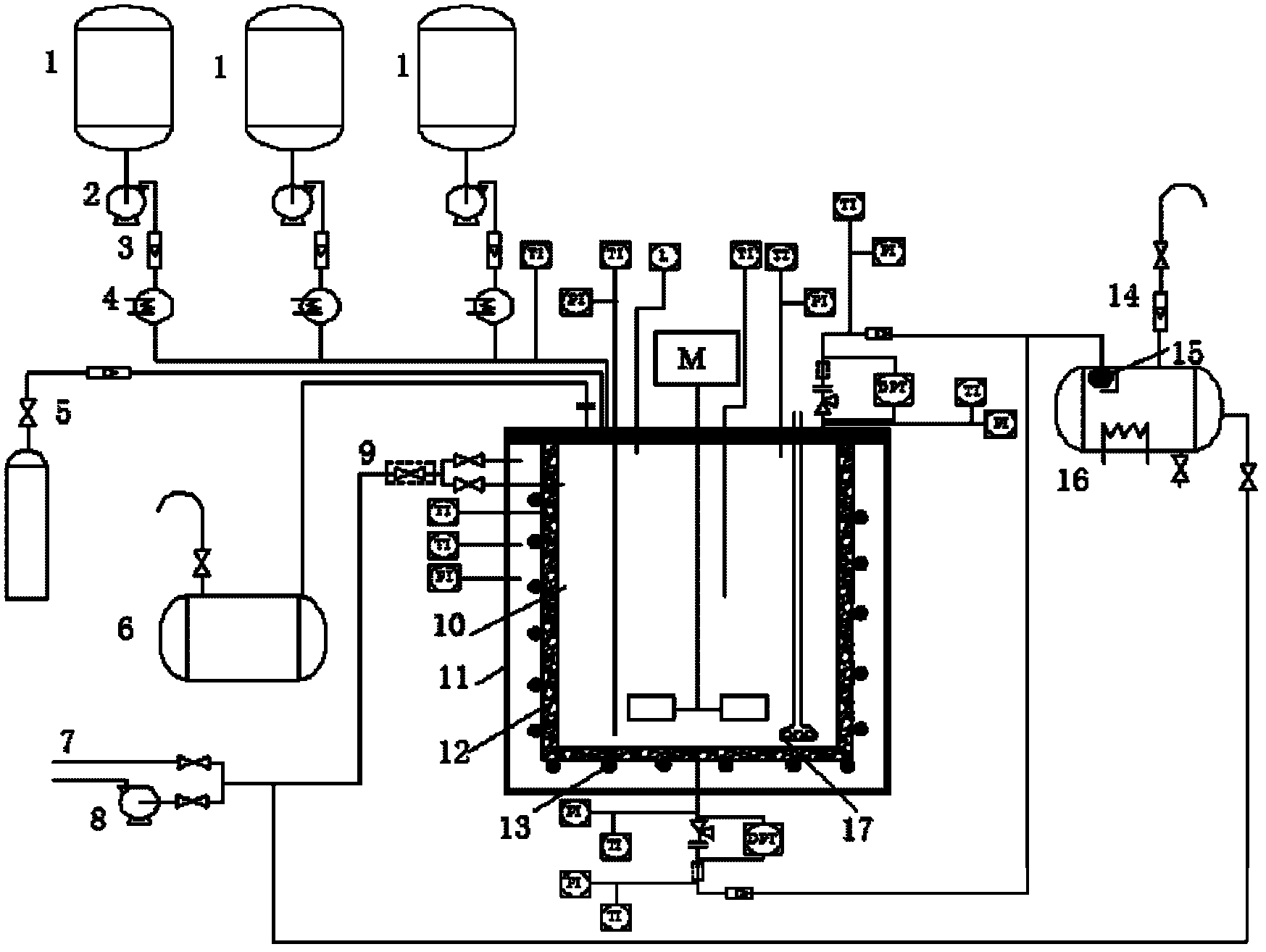

[0025] The simulated experimental device for the emergency release process of reaction out of control in the petrochemical industry according to the present invention mainly includes a reactor 10, a pressure vessel 11, a feeding system, a release control system, a temperature control system, a pressure control system, and a release collection process. system, data acquisition and storage system, automatic operation control system and safety ancillary facilities, such as figure 1 shown.

[0026] (1) Reactor 10

[0027] The internal volume of the reaction kettle 10 is 5L, the maximum pressure difference (positive or negative pressure) is about 0.5MPa, the design temperature is 300°C, and the material is required to be 316L stainless steel. The structure adopts column structure design. Agitation was performed with a mechanical stirrer.

[0028] The reaction kettle 10 has an internal heater 17, which satisfies a heating rate of 1° C. or more per minute. In order to reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com