Secondary package method for cylindrical/tubular materials

A secondary packaging and material technology, applied in packaging and other directions, to achieve the effects of improving production capacity, high degree of automation, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

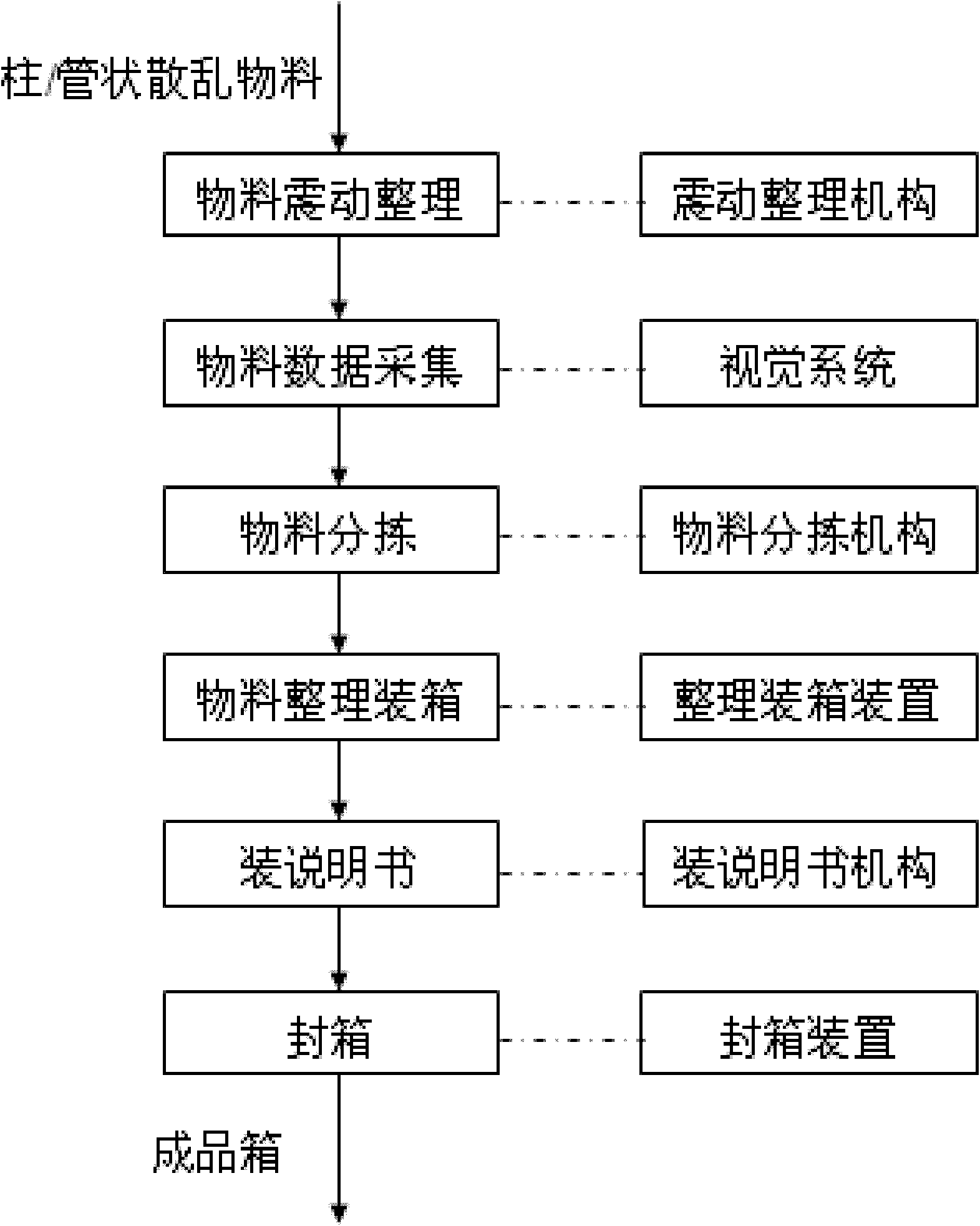

Method used

Image

Examples

Embodiment approach

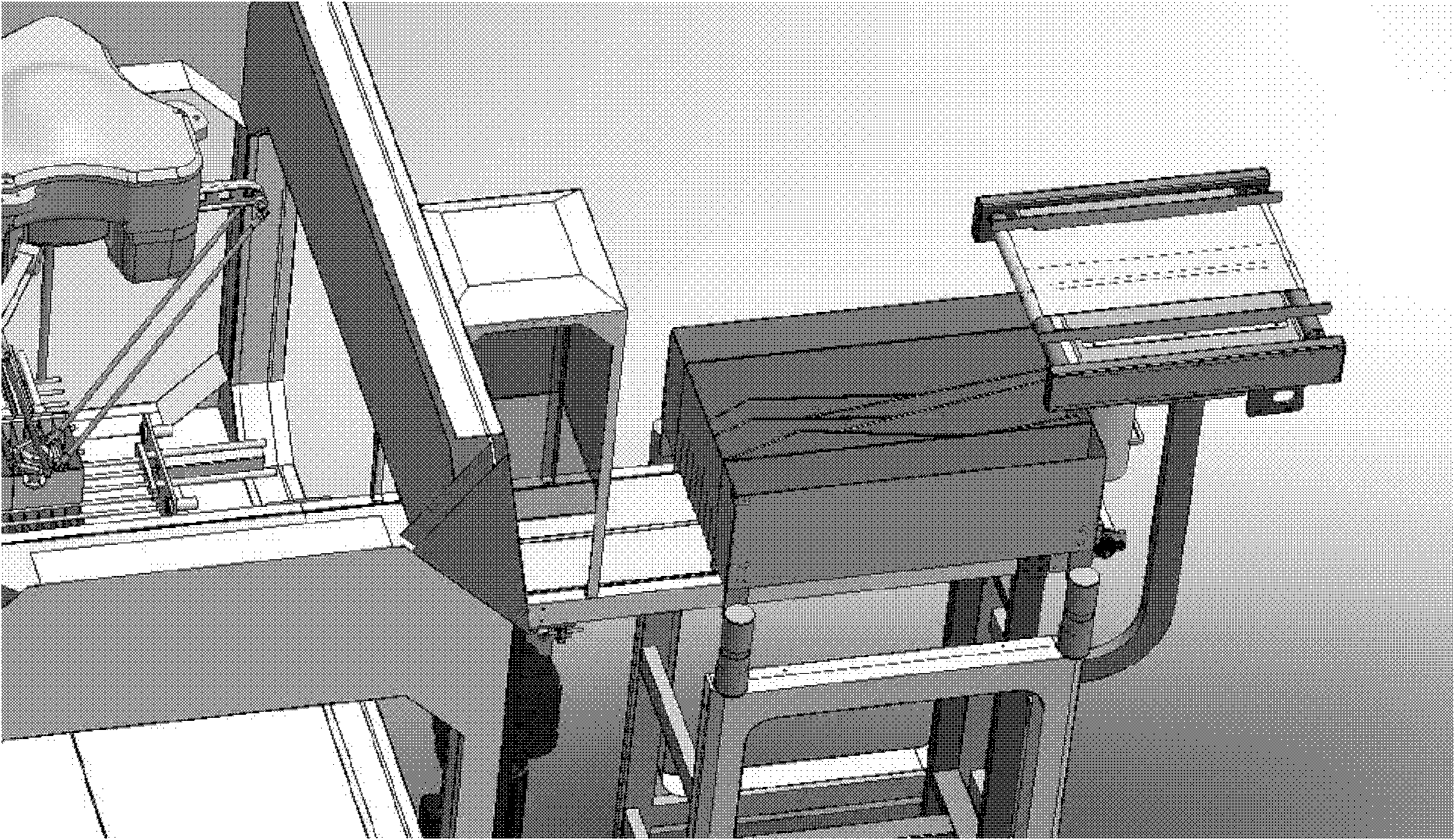

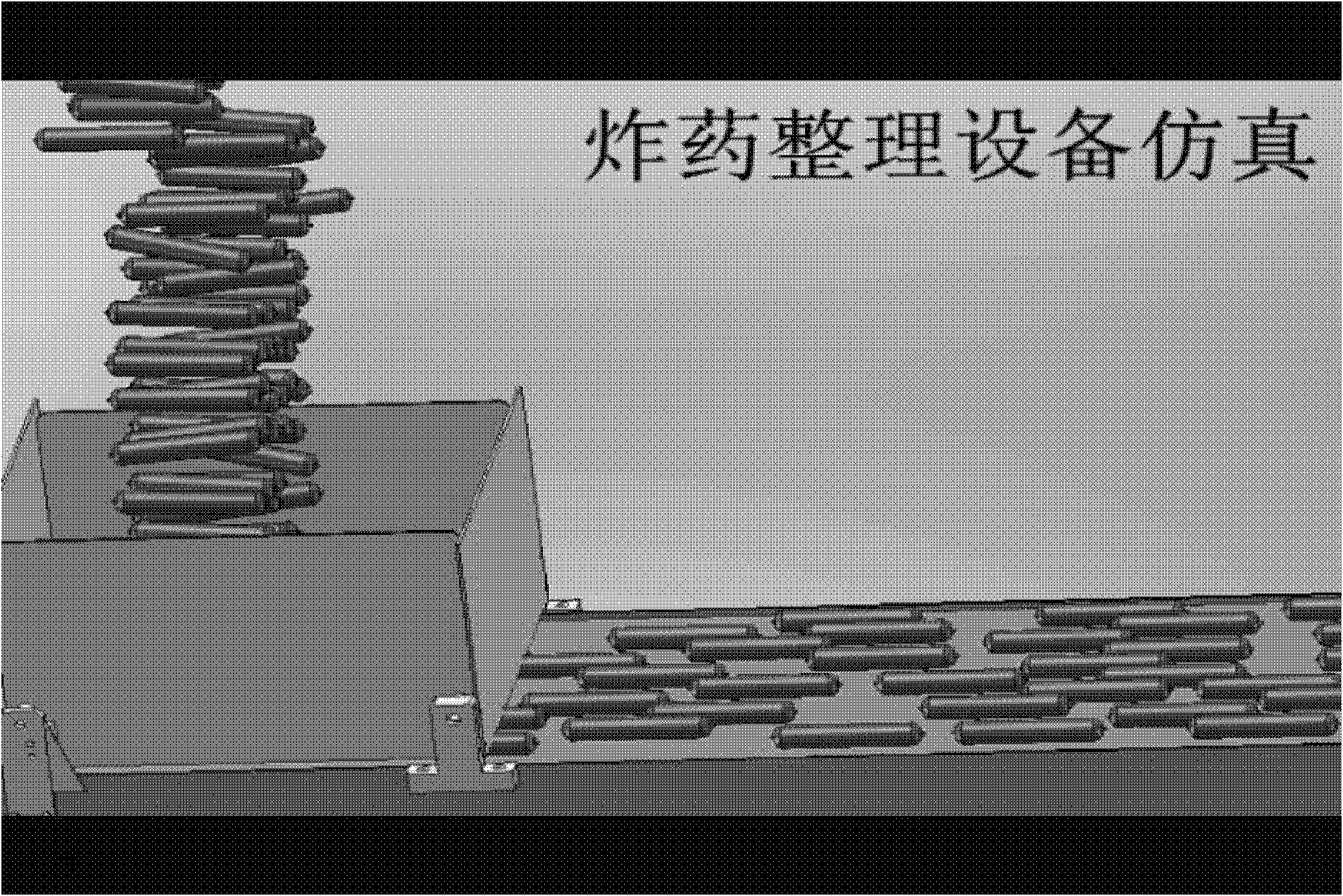

[0041] 1) The material vibration sorting mechanism used in the material sorting link: consists of a base, an eccentric vibrating motor, a sorting box, and a spring. The eccentric vibrating motor is fixed on the finishing box, and the four corners of the finishing box are elastically connected with the base; the finishing box is composed of a group of inclined plates. The orientation of the vibrating materials is generally consistent (the direction is basically consistent with the movement direction of the conveyor belt), that is, the directionality of the medicine rolls is restricted, so that the orientation of the medicine rolls is generally consistent, which is convenient for later data processing.

[0042] 2), the material conveying system mentioned in the material sorting link adopts network chain conveying.

[0043] 3) The vision system in the material data collection link includes a camera, a spotlight and a lampshade.

[0044] 4) The pose data mentioned in the material...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap