Arranging and boxing device

A technology for sorting and packing and sorting mechanisms, applied in the field of mechanical equipment, can solve problems such as poor angle adjustment, unsatisfactory applicability, limited quantity, etc., to achieve improved production efficiency, high packing efficiency, and large packing volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

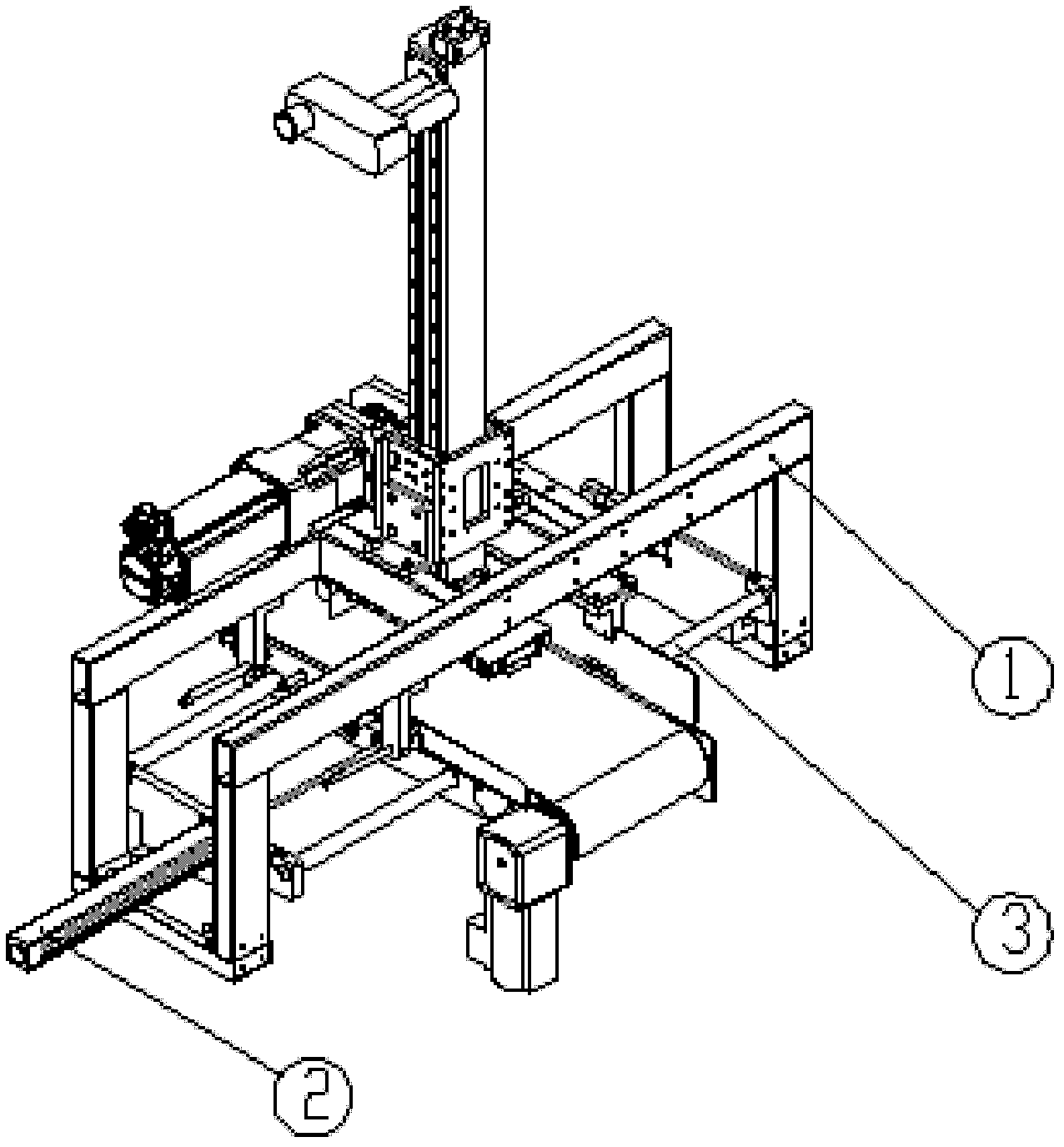

[0024] Example 1: see figure 1 : a kind of vibration finishing mechanism of the present invention, is made up of frame 1, cylinder 2, sliding track 3, finishing mechanism A, boxing mechanism B, and cylinder 2 and sliding track 3 are fixed on the frame 1, and finishing mechanism A is installed on packing Below the box mechanism B.

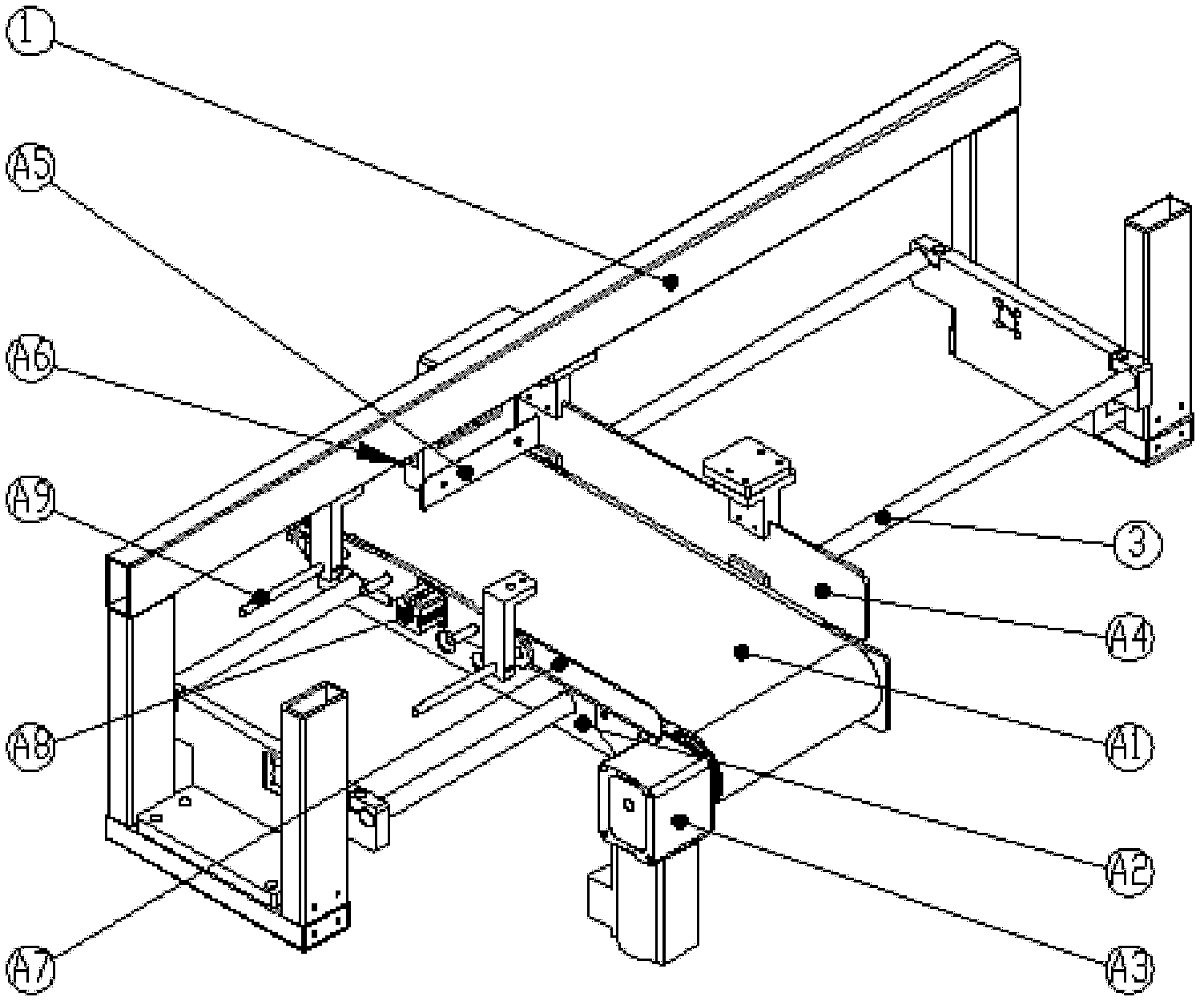

[0025] See figure 2 : The finishing mechanism A is composed of a conveyor belt A1, a supporting wallboard A2, a motor A3, a side baffle A4, a front baffle A5, a front baffle slide bar A6, a push plate A7, a push plate cylinder A8, and a push plate slide bar A9 composition.

[0026] The transmission belt A1, the support wallboard A2 and the motor A3 form a small-scale transmission system, the support wallboard A2 is fixed on the end of the cylinder 2, the sliding track 3 passes through the support wallboard A2, and driven by the cylinder 2, the transmission The small transmission system composed of the belt A1, the supporting wallboard A2 and the...

Embodiment 2

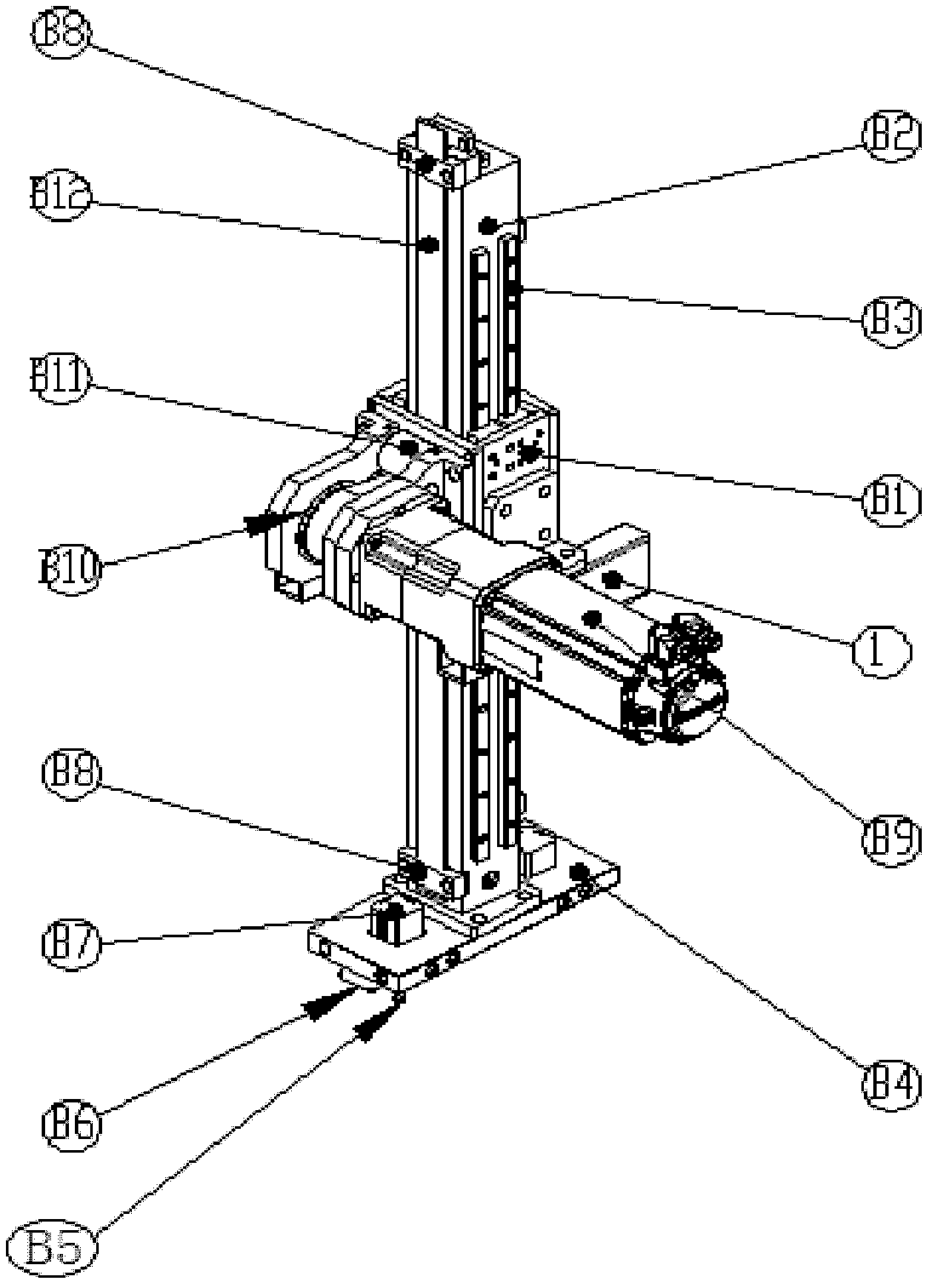

[0030] Embodiment 2: The basic composition of embodiment 2 is exactly the same as that of embodiment 1, the difference is that the arrangement mechanism A is changed from the original cylinder 2 to be fixed on the frame 1, and the packing mechanism B can be driven by the cylinder 2 Sliding along the sliding track 3 in the horizontal direction, as a result, the lifting rod B2 of the packing mechanism B can move in the vertical direction and in the horizontal direction again.

[0031] When in use, the sorting process after a group (several) of products to be packed is conveyed by the belt or sorted by the mechanism to the transmission belt A1 is exactly the same. Push plate A7 of mechanism A retracts, and packing mechanism B first lifts this group of products and then slides in the horizontal direction to avoid sorting mechanism A, and then puts this group of products into the carton below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com