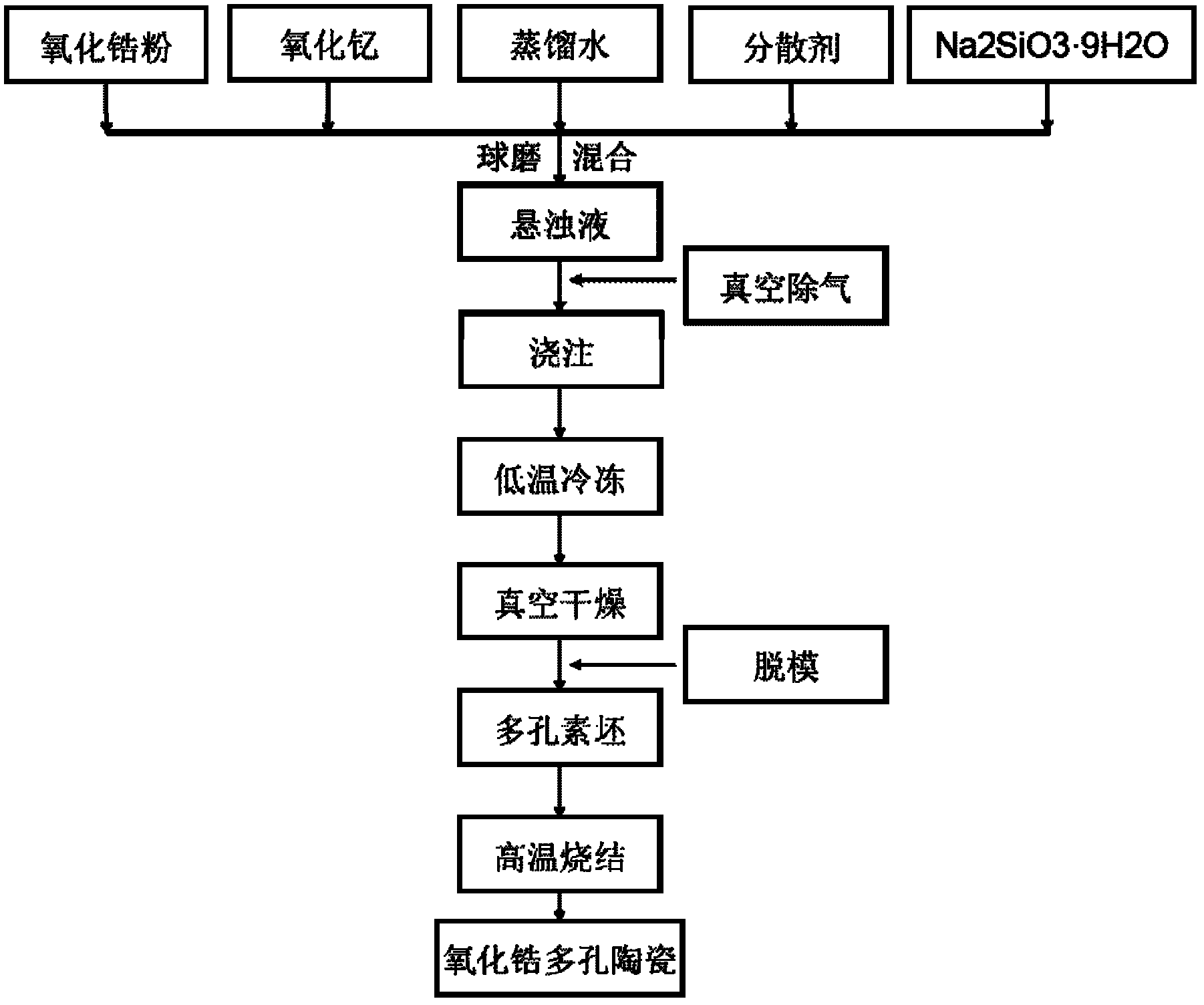

Method for preparing zirconia gradient porous ceramics with ice as template

A gradient porous, zirconia technology, applied in ceramic products, applications, household appliances, etc., can solve the problems of complex preparation process, high cost, easy production, etc., achieve simple operation process, reduce sintering temperature, and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

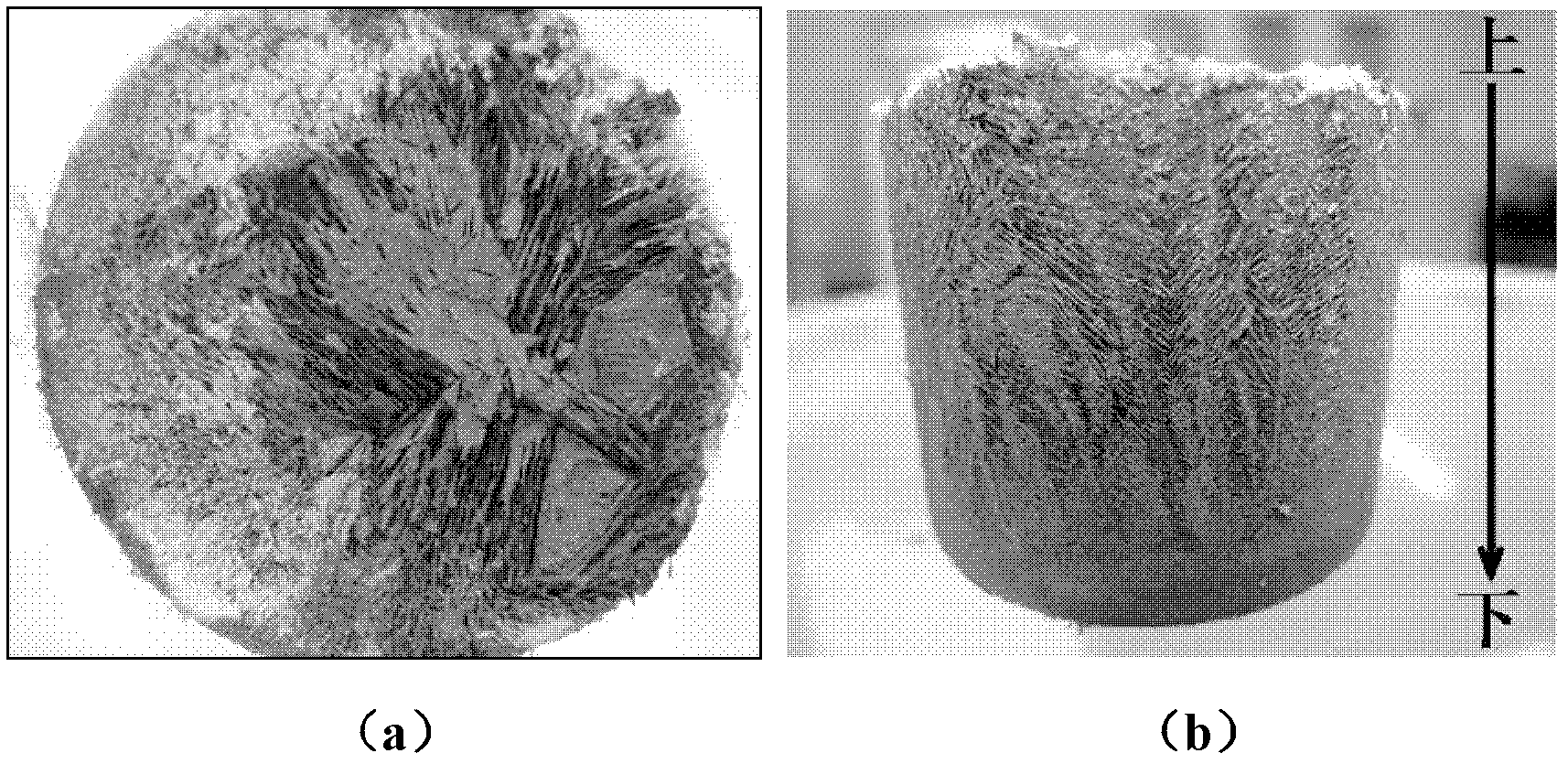

[0038] Embodiment 1: see figure 1 :

[0039] ① First, weigh 100g zirconia powder (Sinopharm Chemical Reagent Co., Ltd.), 200g distilled water, 30g Na 2 SiO 3 9H 2 O binder (Chengdu Jinshan Chemical Reagent Co., Ltd.), 3g yttrium oxide and 2.6g HFXZ-802 type ceramic powder water system dispersant (Hefei Xiangzheng Chemical Technology Co., Ltd.), put into a stainless steel ball mill jar, and add 650g stainless steel Grind the balls, and then use the KQM-X4 / B planetary four-head fast ball mill to carry out full ball milling and mixing for 12 hours to form a stable suspension. The speed of the ball mill is 600 rpm. The ball mill was cooled for 1 hour.

[0040]②Secondly, put the suspension into a closed container connected to a vacuum pump to get rid of the air bubbles generated by the suspension during ball milling;

[0041] ③ Afterwards, inject the suspension into a polypropylene mold, and then place the mold in a vacuum freeze dryer (produced by Beijing Sihuan Scientific In...

Embodiment 2

[0048] ① First, weigh 100g zirconia powder (Sinopharm Chemical Reagent Co., Ltd.), 200g distilled water, 30g Na 2 SiO 3 9H 2 O binder (Chengdu Jinshan Chemical Reagent Co., Ltd.), 3g yttrium oxide and 2.6g HFXZ-802 type ceramic powder water system dispersant (Hefei Xiangzheng Chemical Technology Co., Ltd.), put into a stainless steel ball mill tank, add 650g stainless steel mill Balls, then use the KQM-X4 / B planetary four-head fast ball mill to carry out full ball milling and mixing for 12 hours, and configure it into a stable suspension. Let cool for 1 hour.

[0049] ②Secondly, put the suspension into a closed container connected to a vacuum pump to get rid of the air bubbles generated by the suspension during ball milling;

[0050] ③ Afterwards, inject the suspension into a polypropylene mold, and then place the mold in a vacuum freeze dryer (produced by Beijing Sihuan Scientific Instrument Factory Co., Ltd., model: LGJ-10D) at -30°C to completely freeze the suspension ,...

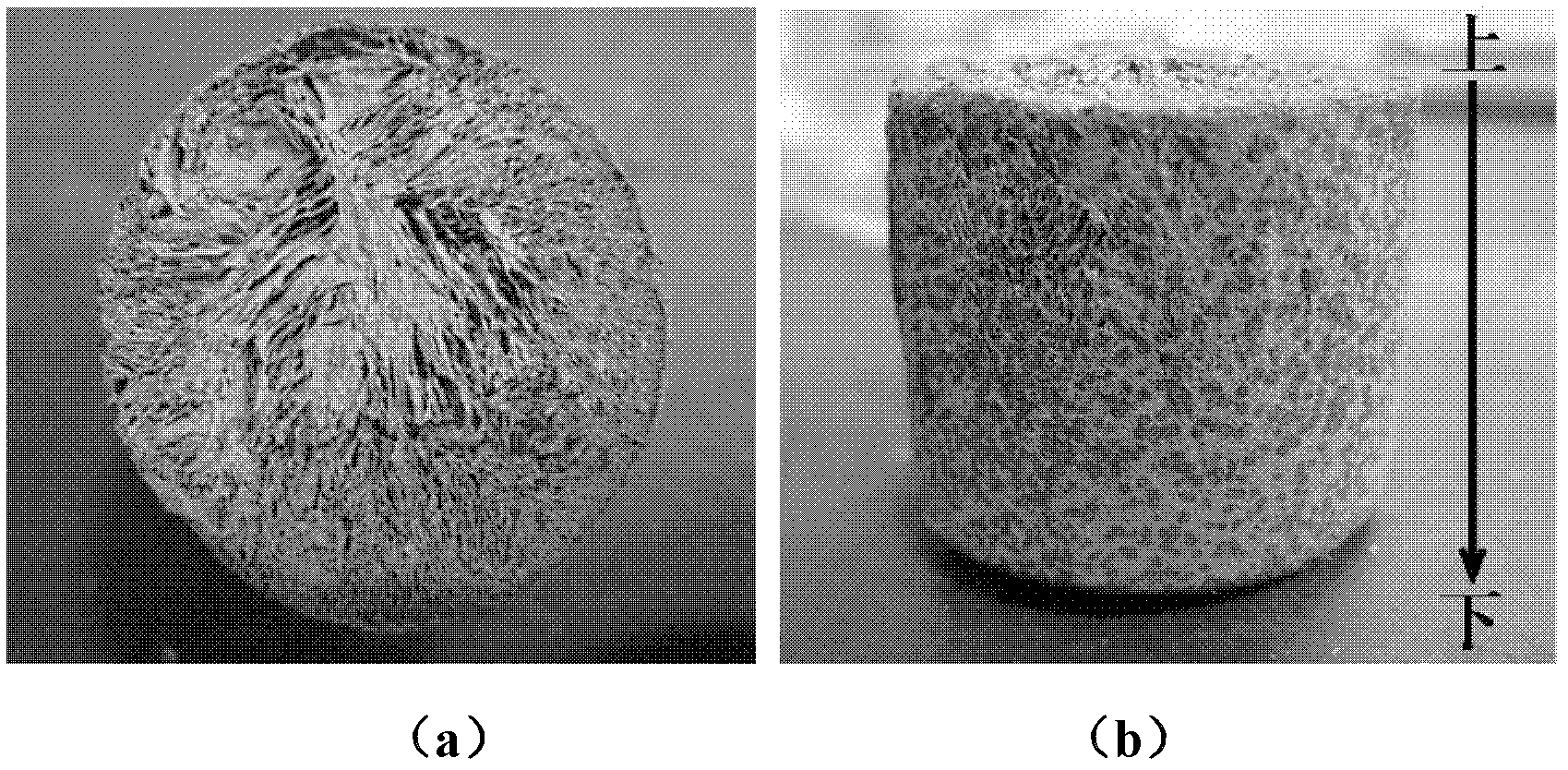

Embodiment 3

[0061] ① First, weigh 100g zirconia powder (Sinopharm Chemical Reagent Co., Ltd.), 300g distilled water, 30g Na 2 SiO 3 9H 2 O binder (Chengdu Jinshan Chemical Reagent Co., Ltd.), 3g yttrium oxide and 2.6g HFXZ-802 type ceramic powder water system dispersant (Hefei Xiangzheng Chemical Technology Co., Ltd.), put into a stainless steel ball mill tank, add 650g stainless steel mill Balls, then use the KQM-X4 / B planetary four-head fast ball mill to carry out full ball milling and mixing for 12 hours, and configure it into a stable suspension. Let cool for 1 hour.

[0062] ②Secondly, put the suspension into a closed container connected to a vacuum pump to get rid of the air bubbles generated by the suspension during ball milling;

[0063] ③Afterwards, inject the suspension into a polypropylene mold, and then place the mold in a vacuum freeze dryer (produced by Beijing Sihuan Scientific Instrument Factory Co., Ltd., model: LGJ-10D) at -30°C to completely freeze the suspension , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com