Furnace protection process for decarburization converter less slag splashing

A decarburization converter and slag splashing technology for furnace protection, applied in the manufacture of converters, etc., can solve the problems of difficult control of the end point, difficulty in meeting the control level and requirements of Japanese steel mills, insufficient slag splashing and protection of furnace slag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

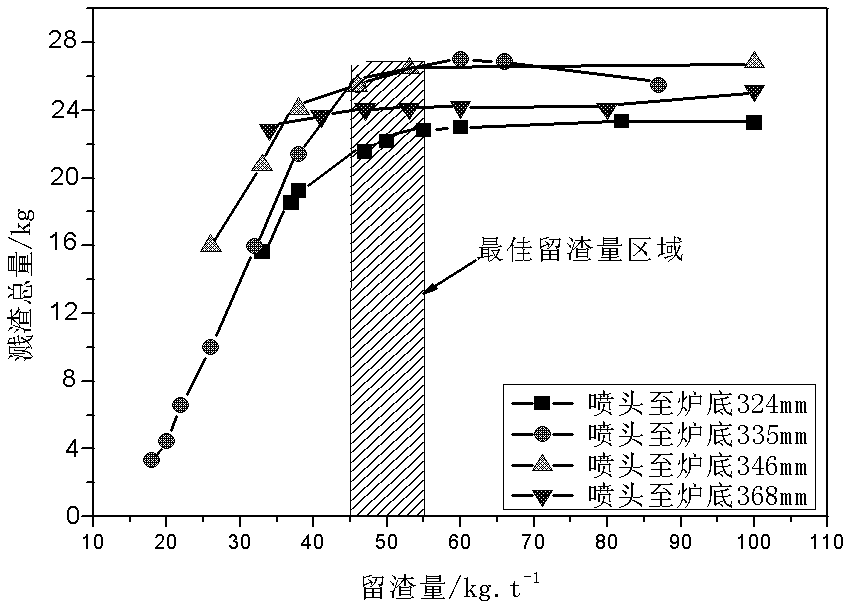

[0032] Embodiment 1: Furnace age 842 furnaces

[0033] No slag dumping after tapping, 2.07kg / t of the modified agent was added after the converter was shaken, 1.38kg / t was lightly burned, 1.91kg / t of the modified agent was added after 74 seconds of slag splashing, and 2.16kg / t was added after 124 seconds. The nitrogen flow rate is 60000Nm 3 / h. The slag splashing gun was opened at 1.5m, and the slag splashing took 148 seconds to drop to 1.2m to maintain the end point, and the slag splashing time was 5:04. Pour off a small amount of liquid slag after slag splashing, and leave 5-15kg / t of slag in the furnace for continued use in the next furnace smelting.

Embodiment 2

[0034] Embodiment 2: Furnace age 882 furnaces

[0035] No slag dumping after tapping, 1.73kg / t of the modified agent was added after the converter was shaken, 1.81kg / t was lightly burned, 1.5kg / t of the modified agent was added after 59 seconds of slag splashing, and 1.88kg / t was added after 153 seconds. The nitrogen flow rate is 60000Nm 3 / h. The slag splashing gun is opened at 1.5m, and the slag splashing takes 132 seconds to drop to 1.2m to maintain the end point, and the slag splashing time is 5:17. Pour off a small amount of liquid slag after slag splashing, and leave 5-15kg / t of slag in the furnace for continued use in the next furnace smelting.

Embodiment 3

[0036] Embodiment 3: furnace age 971 furnace

[0037] No slag dumping after tapping, 1.78kg / t of the modified agent is added after the converter is shaken, 1.76kg / t is lightly burned, 1.5kg / t of the modified agent is added after 62 seconds of slag splashing, and 1.93kg / t is added after 128 seconds. The nitrogen flow rate is 60000Nm 3 / h. The slag splashing gun is opened at 1.5m, and the slag splashing takes 127 seconds to drop to 1.2m to maintain the end point, and the slag splashing time is 5:12. Pour off a small amount of liquid slag after slag splashing, and leave 5-15kg / t of slag in the furnace for continued use in the next furnace smelting.

[0038] Laser thickness measurement comparison of furnaces (furnace age is 827-969 furnaces)

[0039]

[0040] Note: "-" means the thickness growth of the inner furnace lining during the measurement period.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com