Preparation method of braided composite heat insulation layer

A technology of composite materials and heat insulation layers, which is applied in the direction of braids, textiles, and papermaking, can solve the problems of poor heat insulation effect of composite material heat insulation layers, and achieve light weight, good shock absorption performance, and low thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Embodiment 1: Step 1: Make the fiber bundle into a square hollow rod with a certain flexibility;

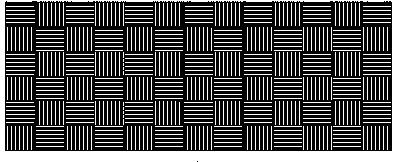

[0015] Step 2: Weave the hollow fiber bundle rods on the required heat insulation components, and weave n (n≤10) hollow rods side by side to form a pattern ( figure 1 );

[0016] Step 3: heating to fully cure the incompletely cured composite material;

[0017] Step 4: Repair the heat insulation layer structure of the braided composite material to meet the requirements of use.

specific Embodiment approach 2

[0018] Embodiment 2: The difference from Embodiment 1 is: Step 1: The fiber bundle is made into a ring-shaped hollow rod with a certain flexibility in cross-section.

specific Embodiment approach 3

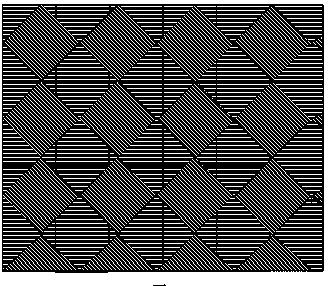

[0019] Embodiment 3: The difference from Embodiment 2 is: Step 2: Weave fiber bundle hollow rods on the required heat insulation components, and weave n (n≤10) hollow rods side by side to form a pattern ( figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com