Water level sensor

A technology of water level sensor and inductance coil, which is applied in the direction of liquid level indicator for physical variable measurement, can solve the problem of inability to adjust the initial resonant frequency, achieve the effect of improving production efficiency and economic benefits, and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

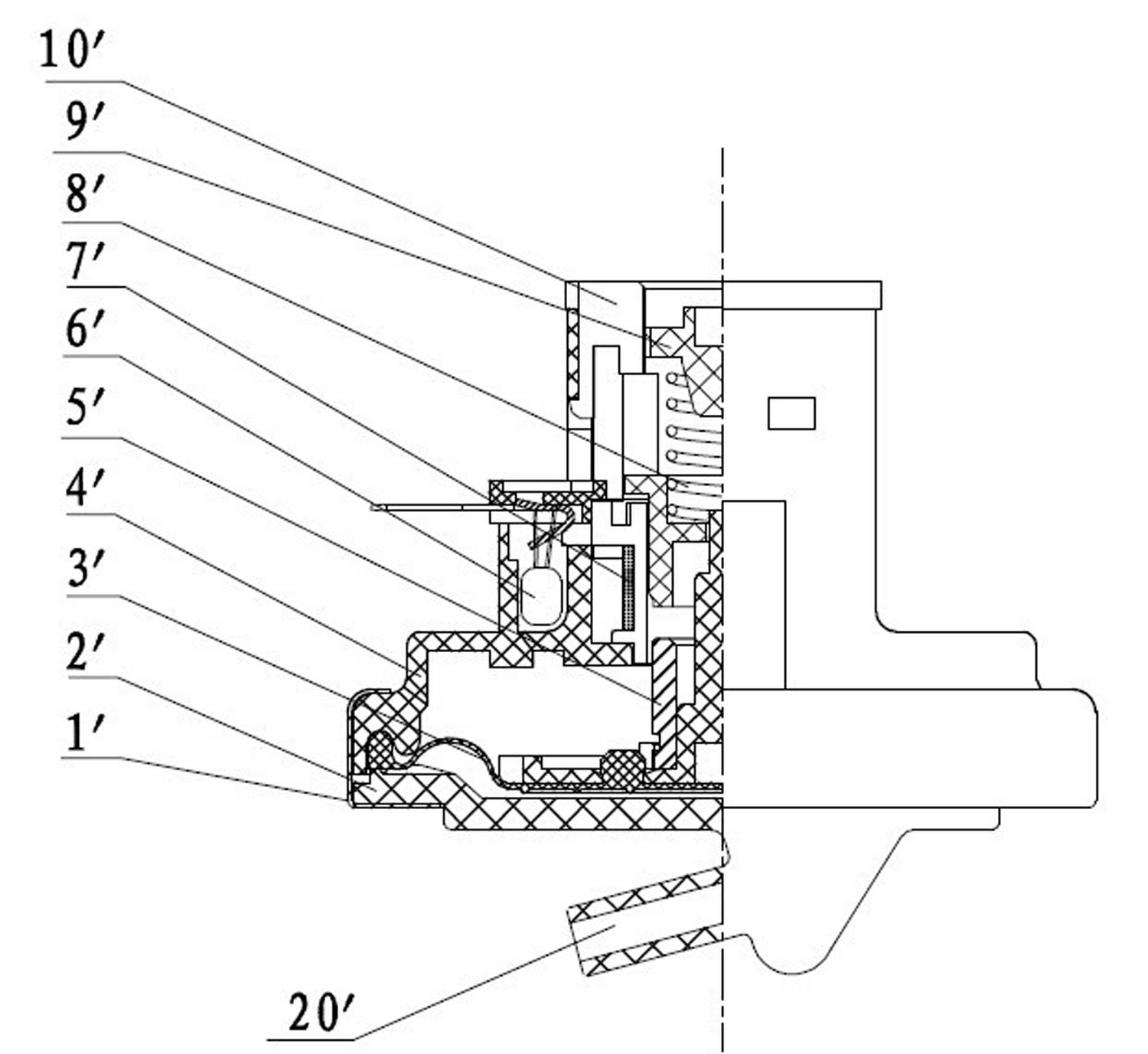

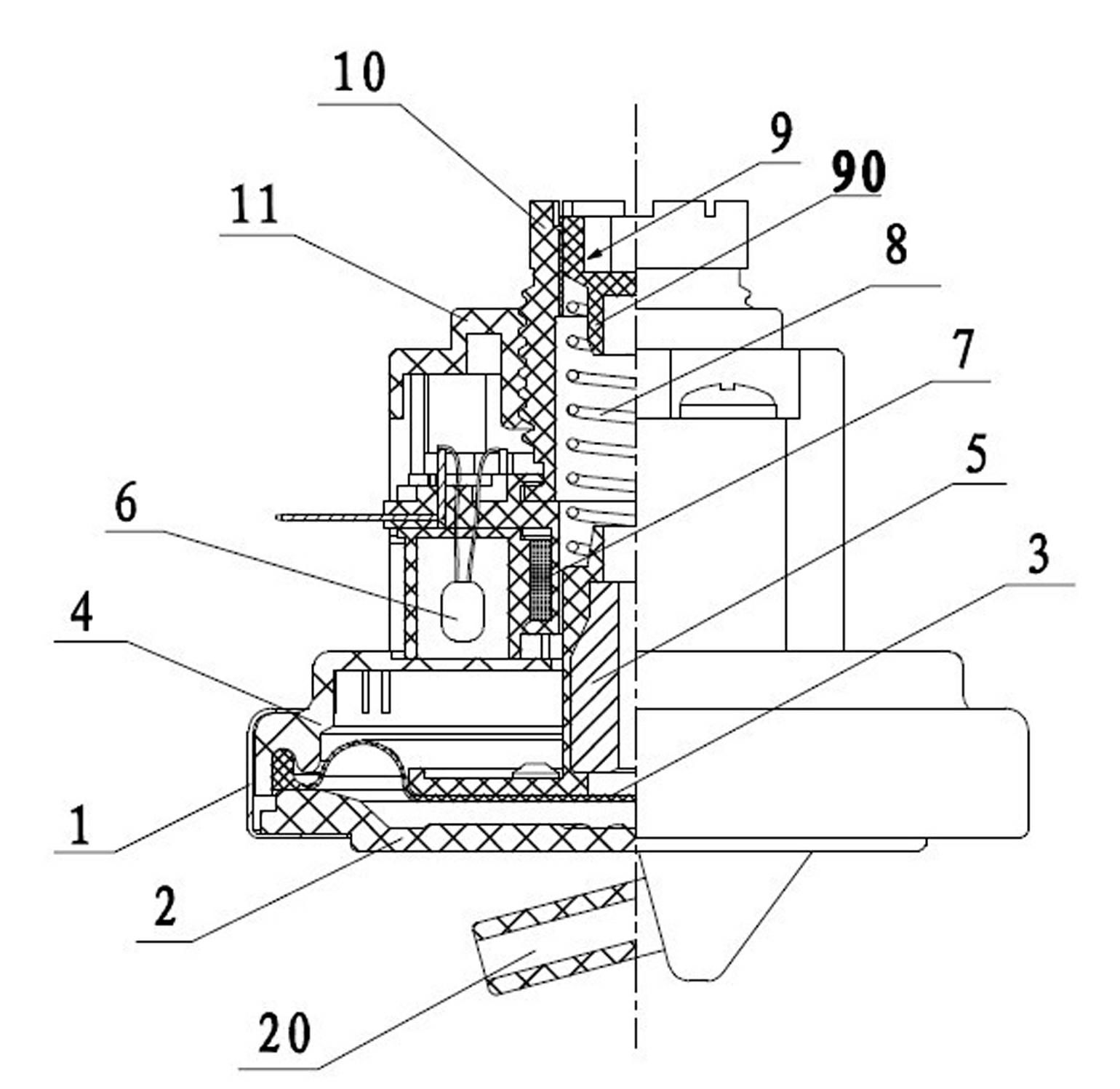

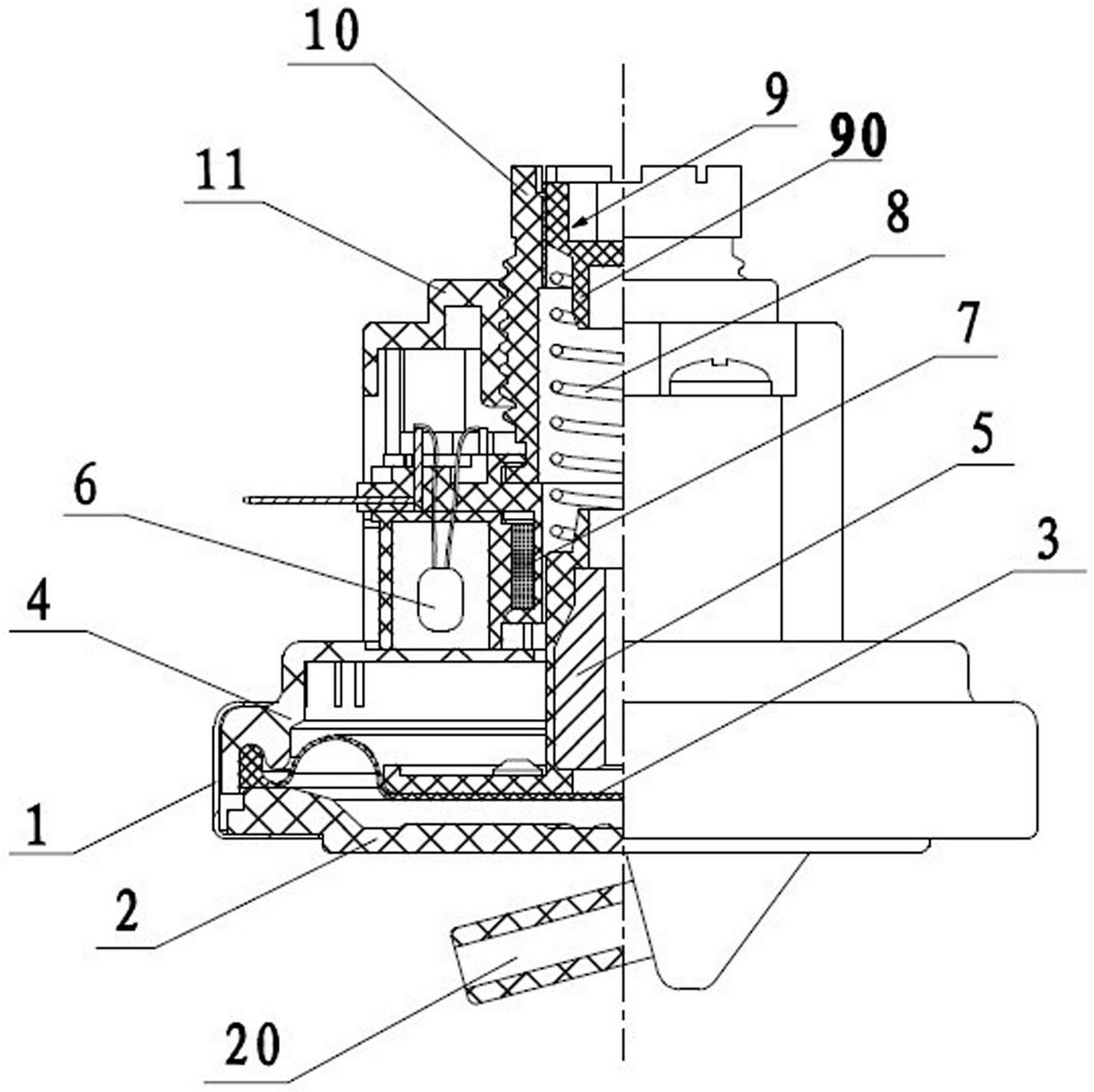

[0020] like figure 2 As shown, the water level sensor of this embodiment includes a base 4, an outer ring 1 covered outside the base 4 for protection, a protective cover 2 arranged at the bottom of the base 4 and having an air inlet nozzle 20, and a cover 2 arranged on the base 4 The sealing disk 3 inside and sealedly connected with the inner wall of the base 4, the magnetic core 5 arranged above the sealing disk 3 and the lower part against the sealing disk 3, the hollow support arranged on the upper part of the base 4, the capacitor 6, the inductor The coil 7 and the spring 8 which is located in the cavity of the hollow support and whose lower end is pressed against the magnetic core 5, according to this embodiment, the hollow support includes a hollow first support 10 and is arranged on the outer periphery of the first support 10 and is connected to the base The second bracket 11 fixedly connected to the seat 4, the inductance coil 7 and the capacitor 6 are fixed on the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com