Operating mechanism of modularized breaker

An operating mechanism and circuit breaker technology, applied in the protection switch operation/release mechanism, circuit, and components of the protection switch, etc., can solve the problems of the circuit breaker contact not being energized, the thermoplastic fixed connection strength is low, and the pollution removal is difficult. , to achieve the effect of improving product reliability and life, easy large-scale automated production, and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

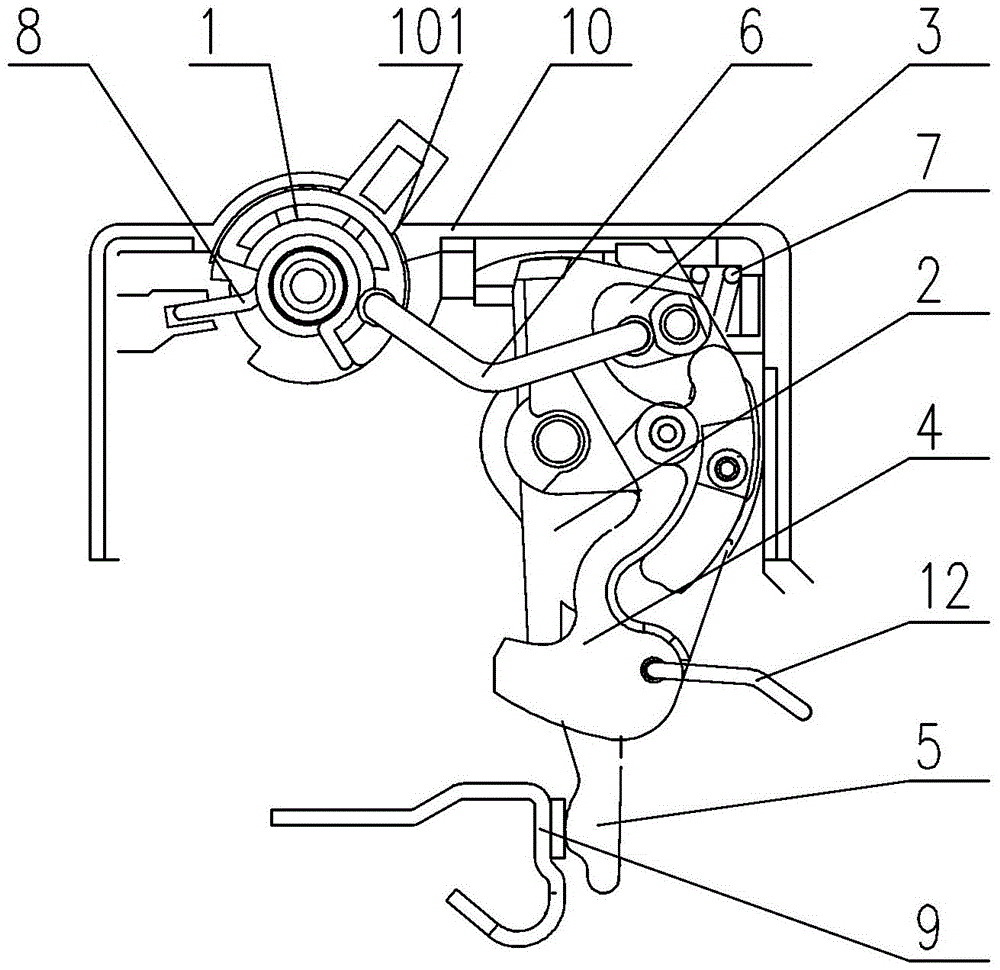

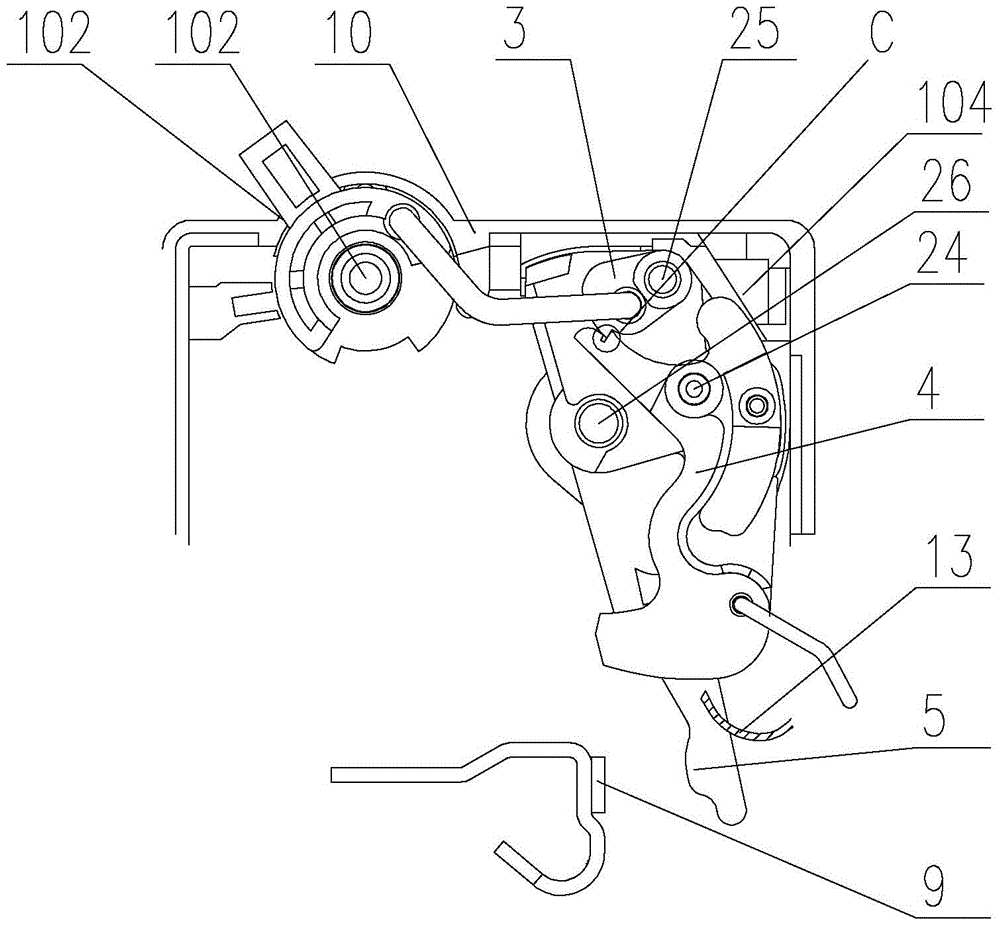

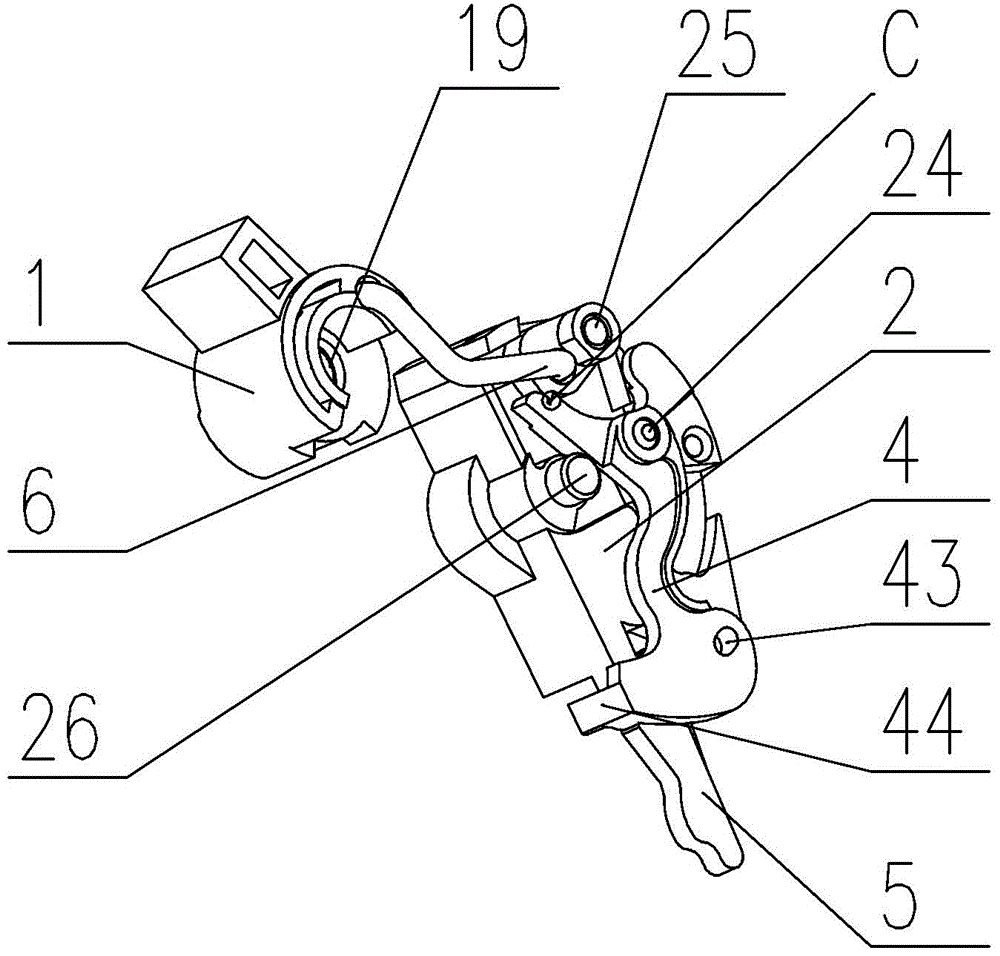

[0021] The specific implementation of the operating mechanism of the modularized circuit breaker of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings, taking the miniature circuit breaker as an example. The operating mechanism of the modular circuit breaker of the present invention is not limited to the description of the following embodiments.

[0022] see Figures 1 to 6 The operating mechanism of the miniature circuit breaker shown includes a circuit breaker case 10, a lever 3, a lock 4, a moving contact 5, an operating handle 1 and a contact support 2 that are pivotally mounted on the circuit breaker case 10, and a fixed installation The static contact 9 on the circuit breaker case 10, the return spring 8 connected to the circuit breaker case 10 and the operating handle 1 respectively, the energy storage spring 7 connected to the circuit breaker case 10 and the contact support 2 respectively, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com