Front potato harvester for walking tractor

A walk-behind tractor, front-mounted technology, which is applied to excavator harvesters, agricultural machinery and implements, excavators, etc. Small resistance, good for picking up, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

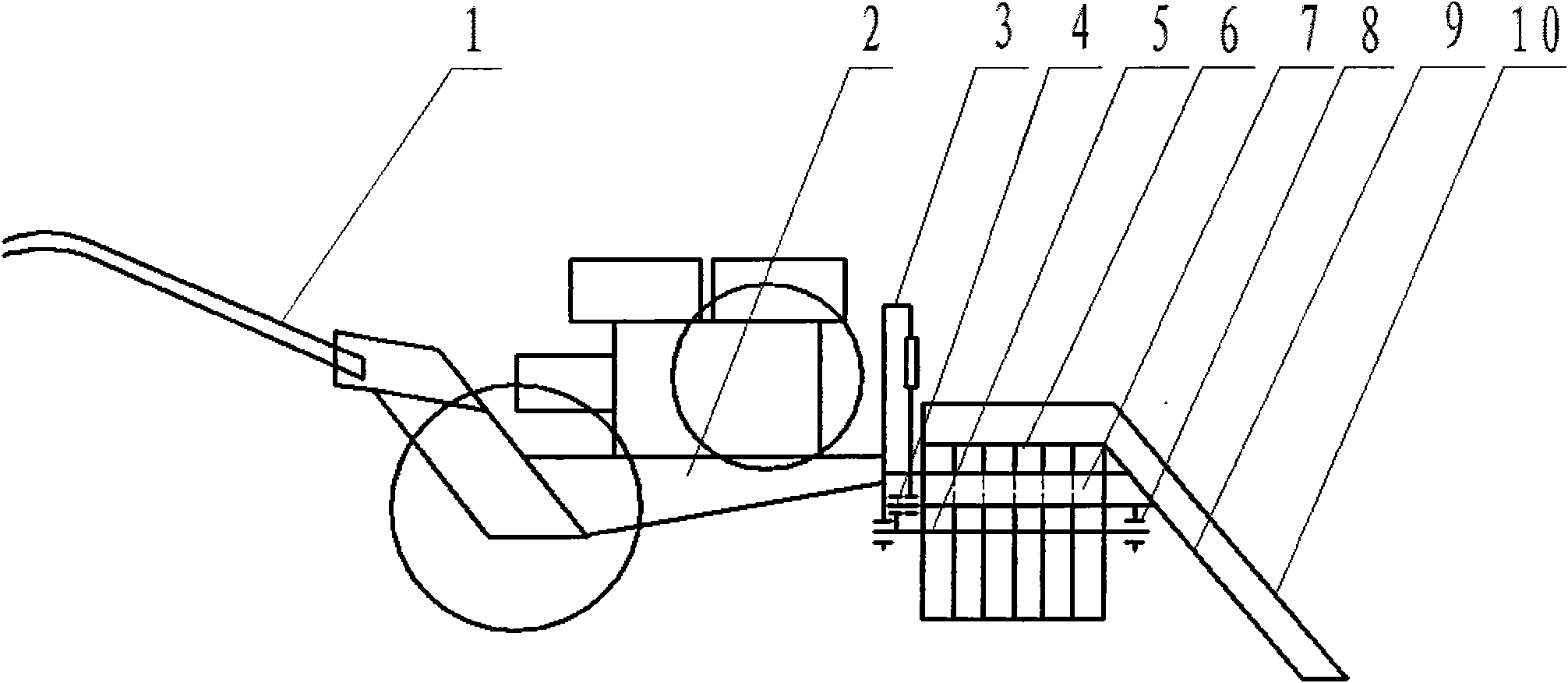

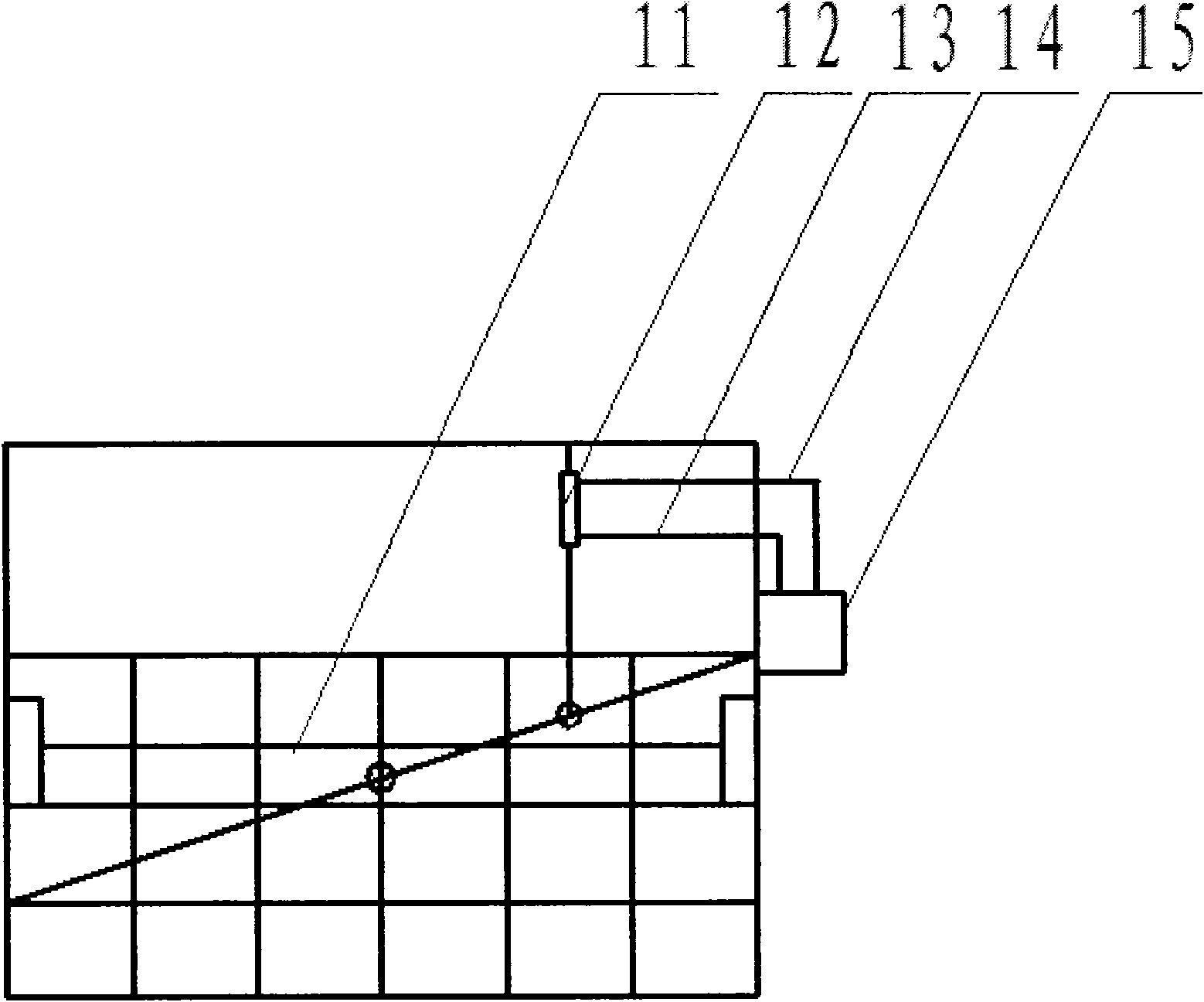

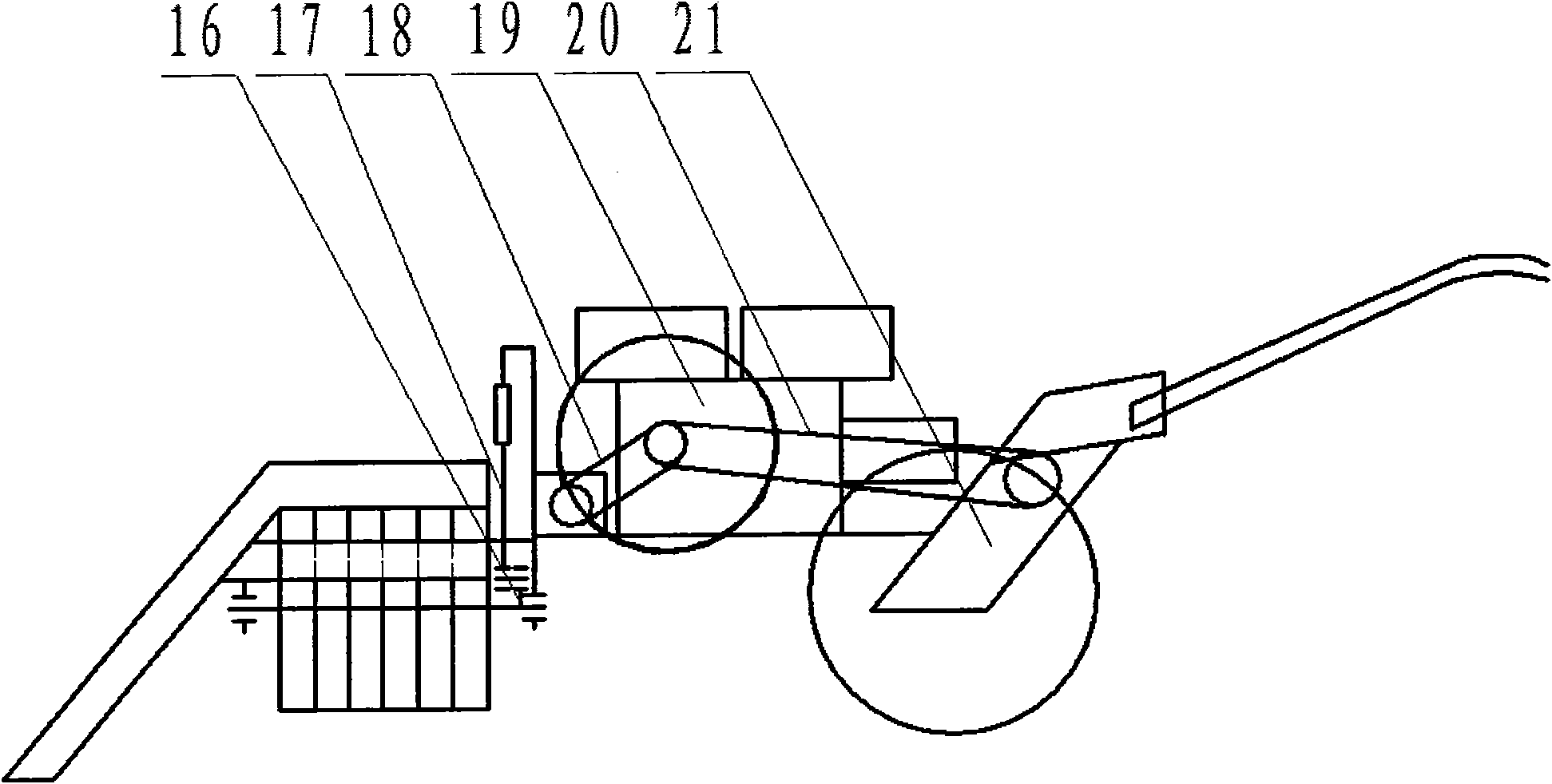

[0010] The utility model relates to a front-mounted potato harvester of a walk-behind tractor. It consists of walking tractor 1, walking tractor frame 2, mounting frame 3, driving handle pin shaft 4, discharge plate shaft 5, discharge plate 6, digging plow fixing plate 7, discharge shaft bearing 8, grid-shaped digging plow Plow blade 9, excavated plow baffle 10, fixed plate beam 11, double-acting oil cylinder 12, oil cylinder lower oil pipe 13, oil cylinder upper oil pipe 14, oil pump 15, shaft driving handle 16, oil cylinder shaft connecting rod 17, oil pump transmission belt 18, diesel engine 19. Walking tractor transmission belt 20 and walking tractor gearbox 21 are composed. The mounting frame 3 is installed on the front end of the walking tractor frame 2, and the installation position can be adjusted by moving up and down at the front end of the walking tractor frame 2 as required, and the driving handle pin 4 is connected with the rotating shaft driving handle 16 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com