Surface treatment protective wax removing cabinet

A technology for surface treatment and protection of wax, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve manual cleaning and drying of parts, environmental and human hazards, not suitable for larger parts, etc. problem, to achieve the effect of low manufacturing cost, convenient operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

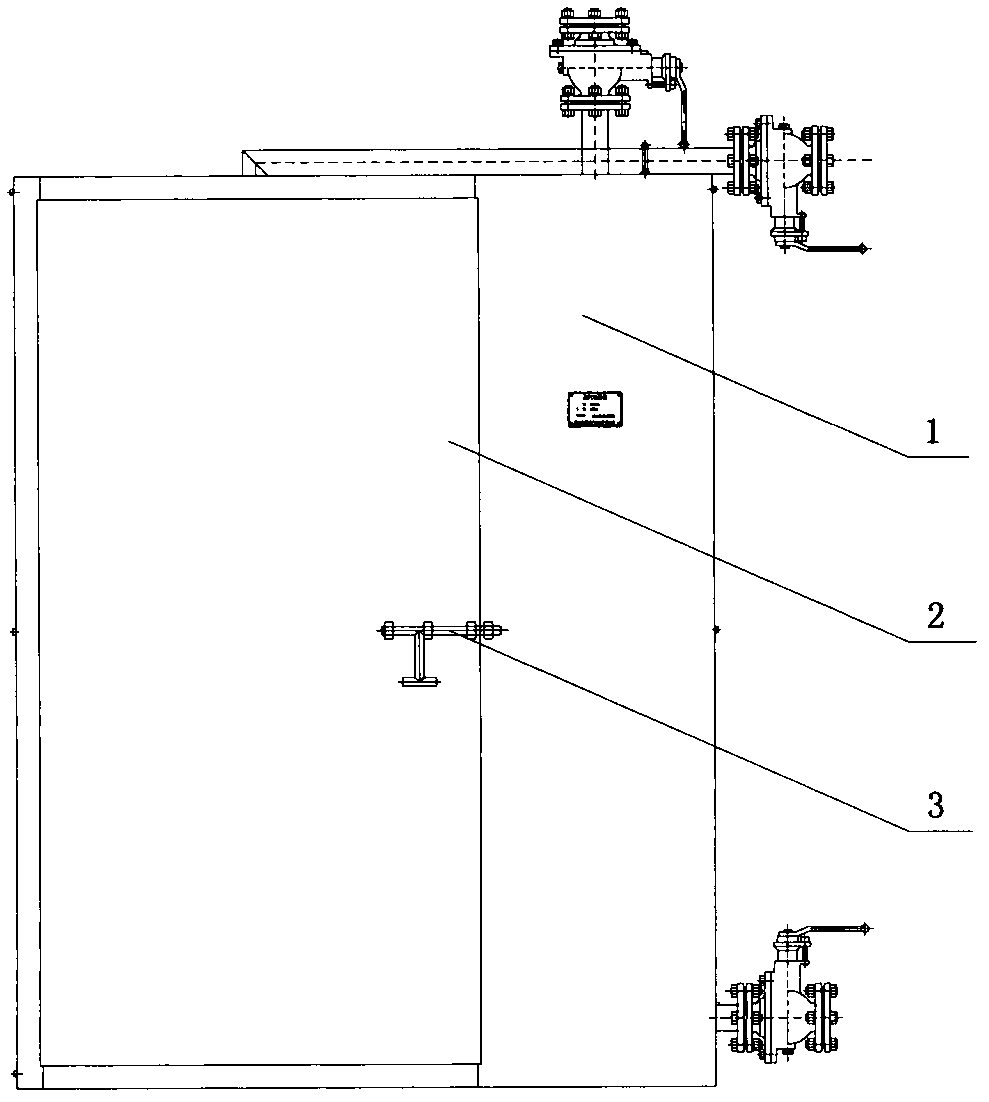

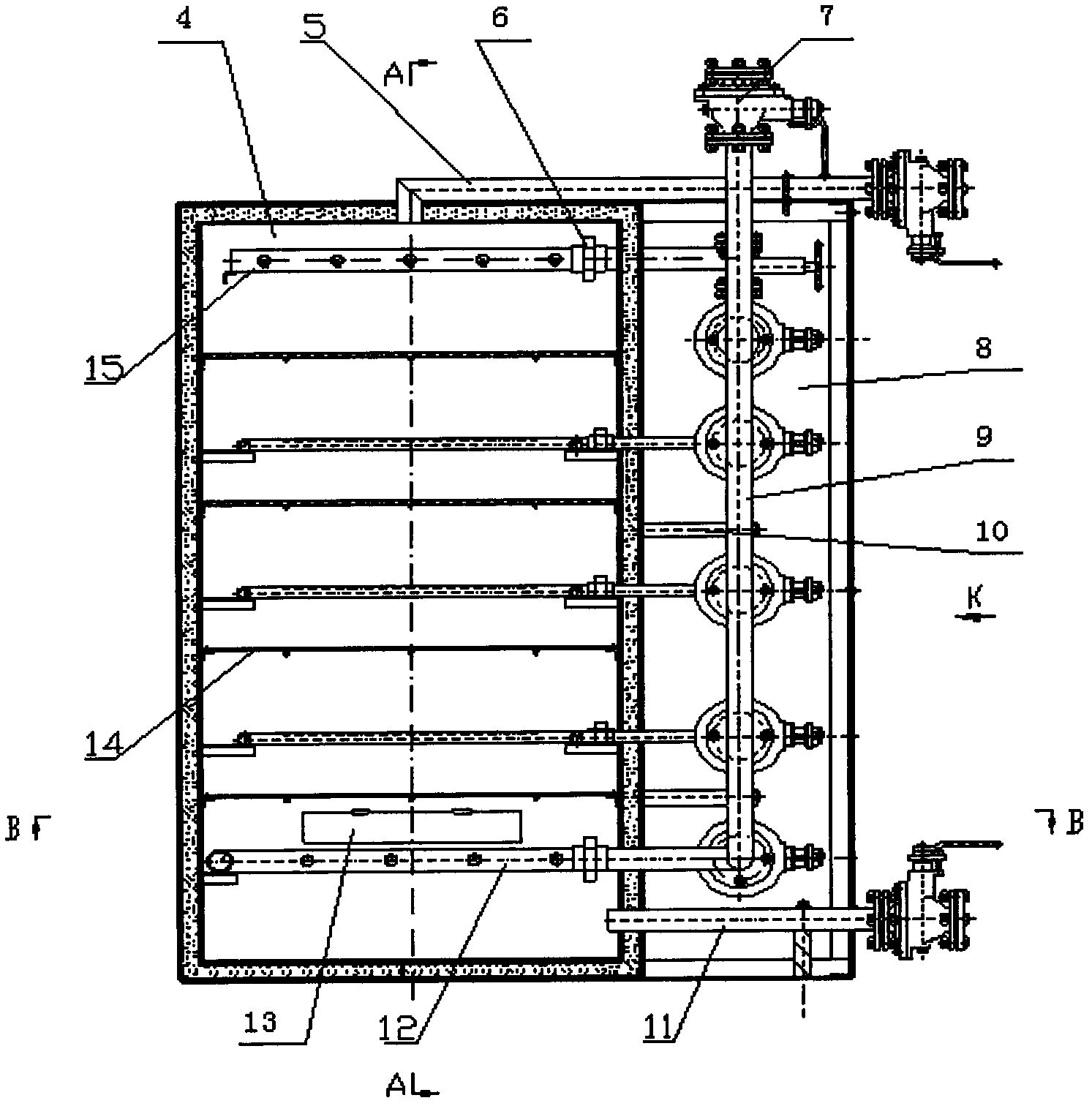

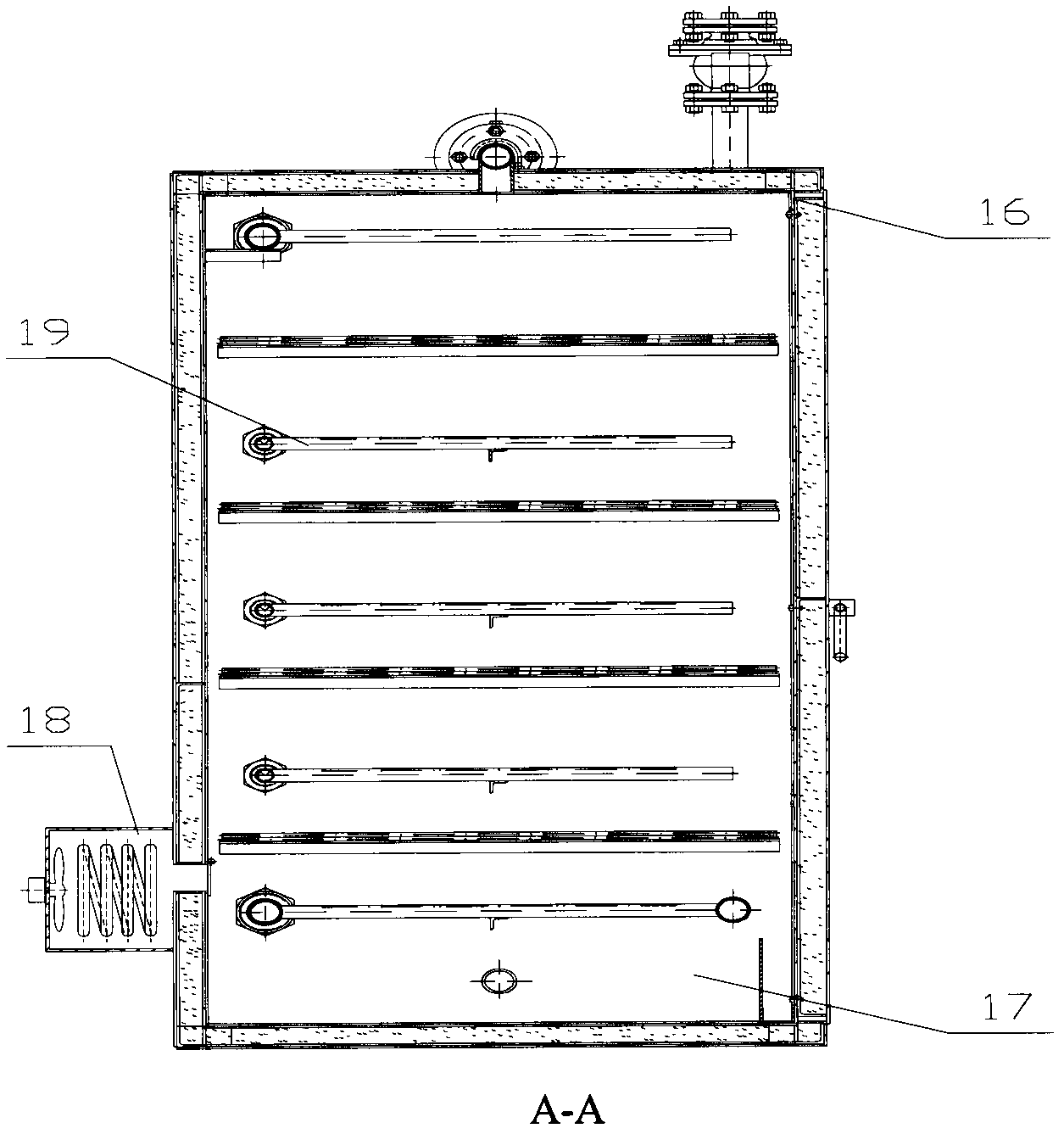

[0037] This embodiment is a surface treatment protection wax removal cabinet, which is composed of a wax removal room 4 and a control room 8. There is insulation in the walls of the wax removal booth. There is a bottom layer steam nozzle 12 at the inner bottom of the wax removal room; above the bottom layer steam nozzle 12, three layers of middle layer steam nozzles 19 are arranged up and down. There is a top cleaning nozzle 15 at the top of the wax removal room. Four layers of parts grates 14 are distributed between the top cleaning spray pipe 15, the three-layer middle layer steam spray pipe 19 and the bottom steam spray pipe 12. The top cleaning spray pipe 15, the three-layer middle layer steam spray pipe 19, the bottom steam spray pipe 12 and the four-layer part grate 14 are all arranged horizontally. The hot blast valve 13 is located above the bottom steam nozzle 12 and is fixed on one side inner wall of the wax removal room 4 . On the side wall of the wax removal room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com