Multiroll mill stand processing method and fixture device

A rolling mill and stand technology, which is applied in the field of multi-roll mill stand processing methods and tooling devices, can solve the problems of inability to meet the multi-roll mill rolling operation accuracy requirements, and achieves simple structure, high machining accuracy, and optimal boring. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

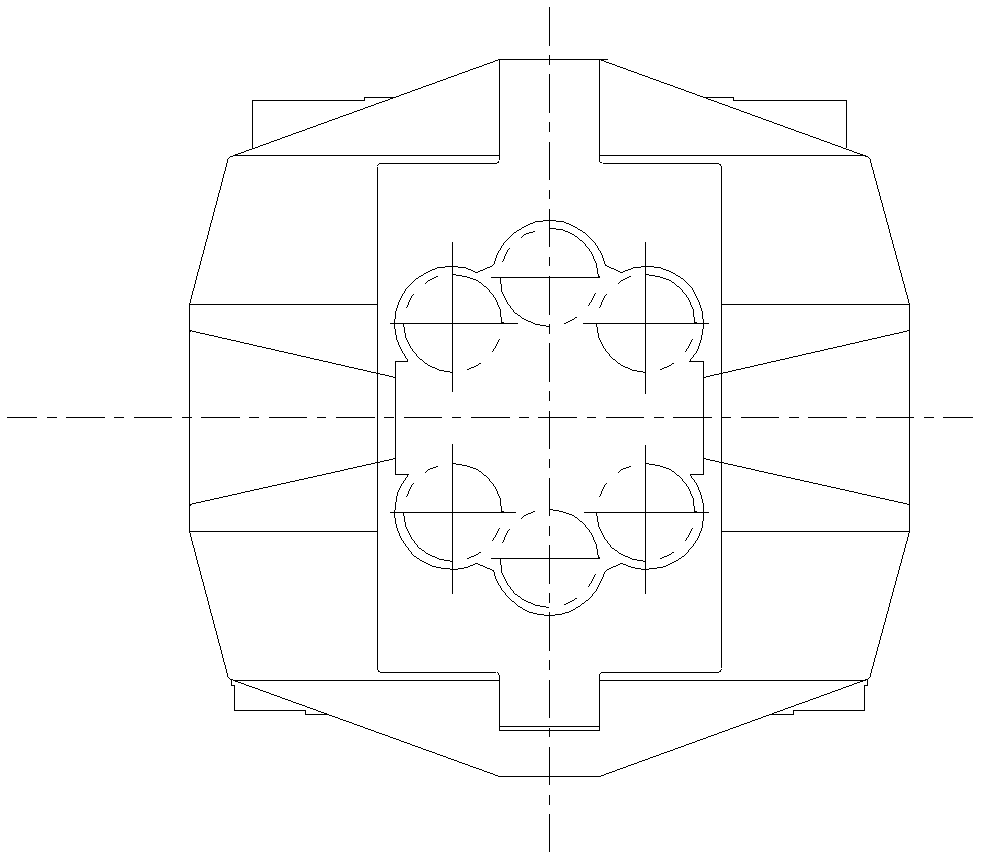

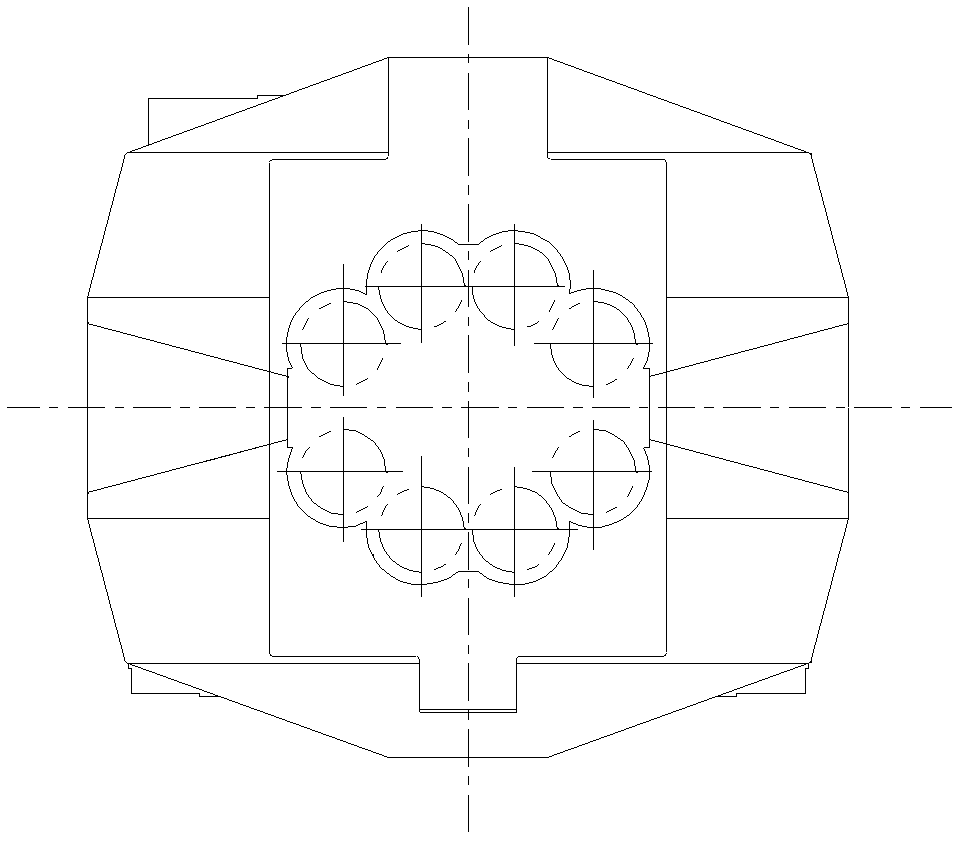

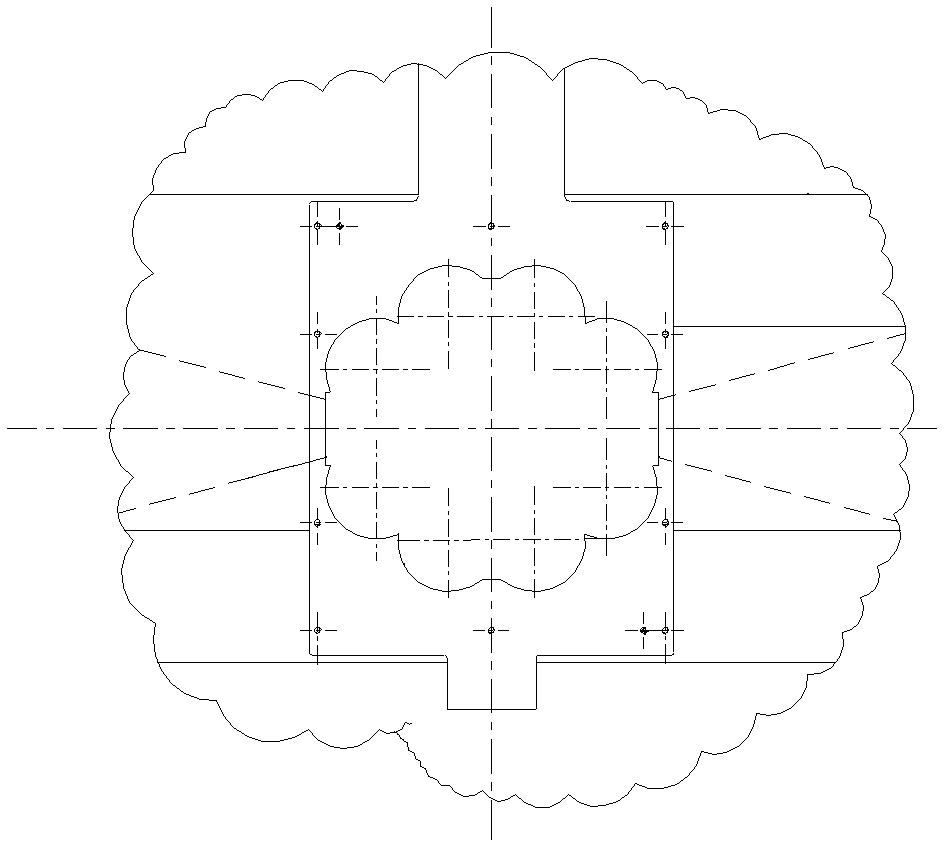

[0041] Please refer to Figure 4 , Figure 5 , are respectively the structural schematic diagram of the tooling device used for processing multi-roll rolling mill racks of the present invention in use and the structural schematic diagram of the boring die of the tooling device of the present invention. like Figure 4As shown, the tooling device proposed by the present invention for processing the multi-roll mill frame 100 is driven by the boring shaft 6 on one side of the boring machine 1, and includes a floating boring bar 2, a left boring die 3, a right boring die 4 and a boring tool Component 5, one end of the floating boring bar 2 is detachably connected with the boring shaft 6 through the cardan shaft 7, and the floating b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap