Checking tool for door trim of car

A door trim and tooling technology, applied in the field of car door trim calibration tooling, can solve problems such as affecting product quality, unable to achieve precise positioning, etc., and achieve the effect of fast locking speed, accurate correction and product quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

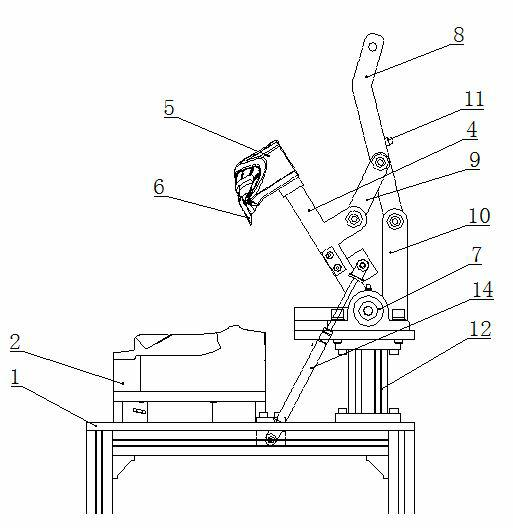

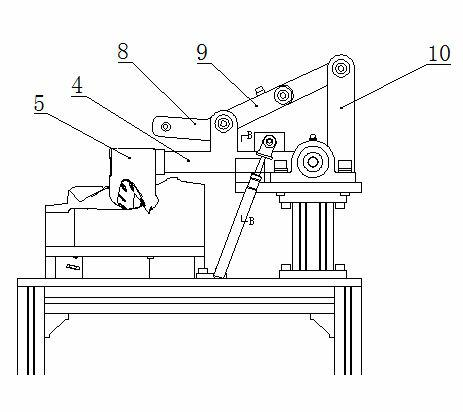

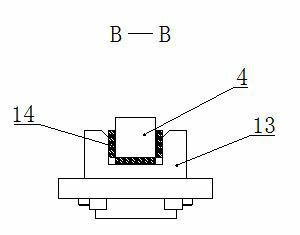

[0017] Such as figure 1 , 2 As shown, it includes base 1, tire mold 2, support 12, bearing seat 7, rocker arm 4, clamp seat 5, calibration clamp 6, handle 8, connecting rod 9, handle turning bracket 10, handle turning limit Bit block 11, nitrogen gas spring 14.

[0018] A tire mold 2 is fixed on the above-mentioned base 1, and the mold cavity of the tire mold 2 can just be fitted with the lower surface of the frame of the car door trim, and a mechanism for locking the skeleton is arranged in the tire mold 2.

[0019] In this embodiment, the skeleton locking mechanism is a fully automatic logic air hole mechanism, which specifically includes a vacuum chuck 31, an air control opening switch 32, a vacuum generator 33, an air control valve 34, and an air control closing switch 35, such as Figure 4 As shown, there are several vacuum suction cups 31, which are evenly distributed at the bottom of the cavity of the tire mold 2. The air control opening switch 32 is a limit switch, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com