Fiber placement press roller mechanism capable of adjusting fiber prepreg tape and press roller wrap angle

A technology of fiber laying and pressing roller mechanism, applied in the field of resin-based composite material manufacturing, can solve the problems of destroying preforms, reducing the reliability of fiber laying equipment, poor bonding performance, etc., so as to improve reliability and improve poor Effects, easy to apply effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

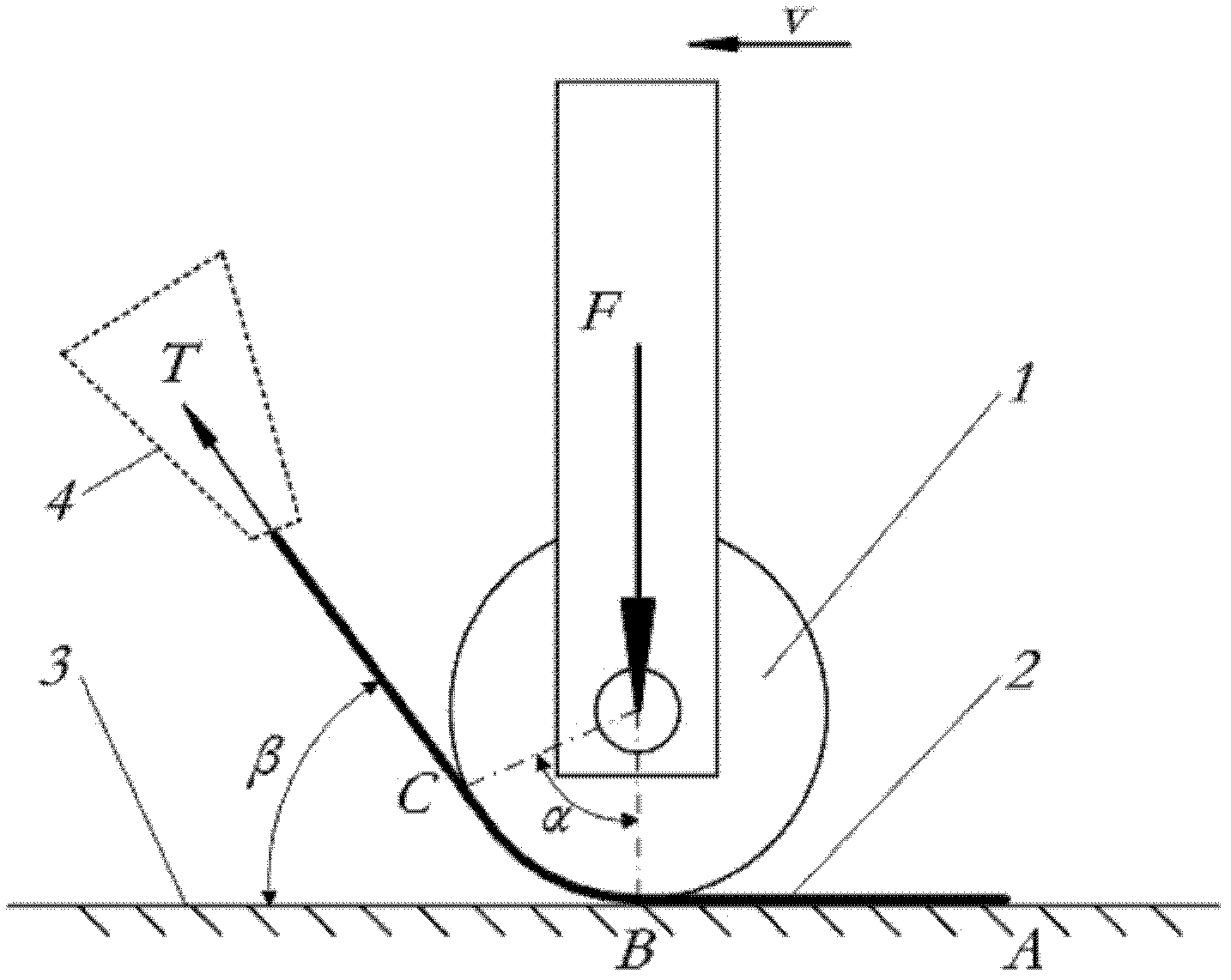

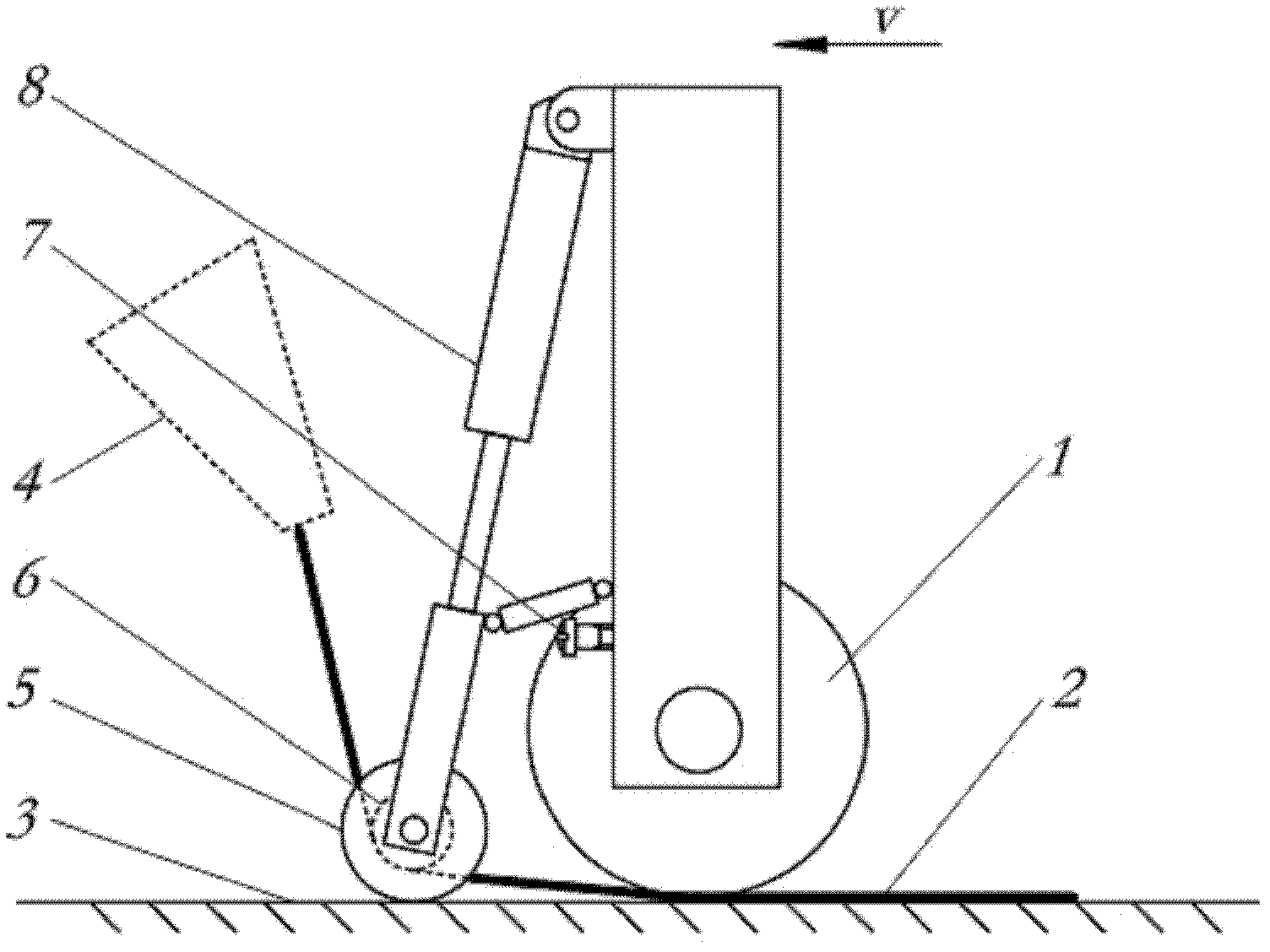

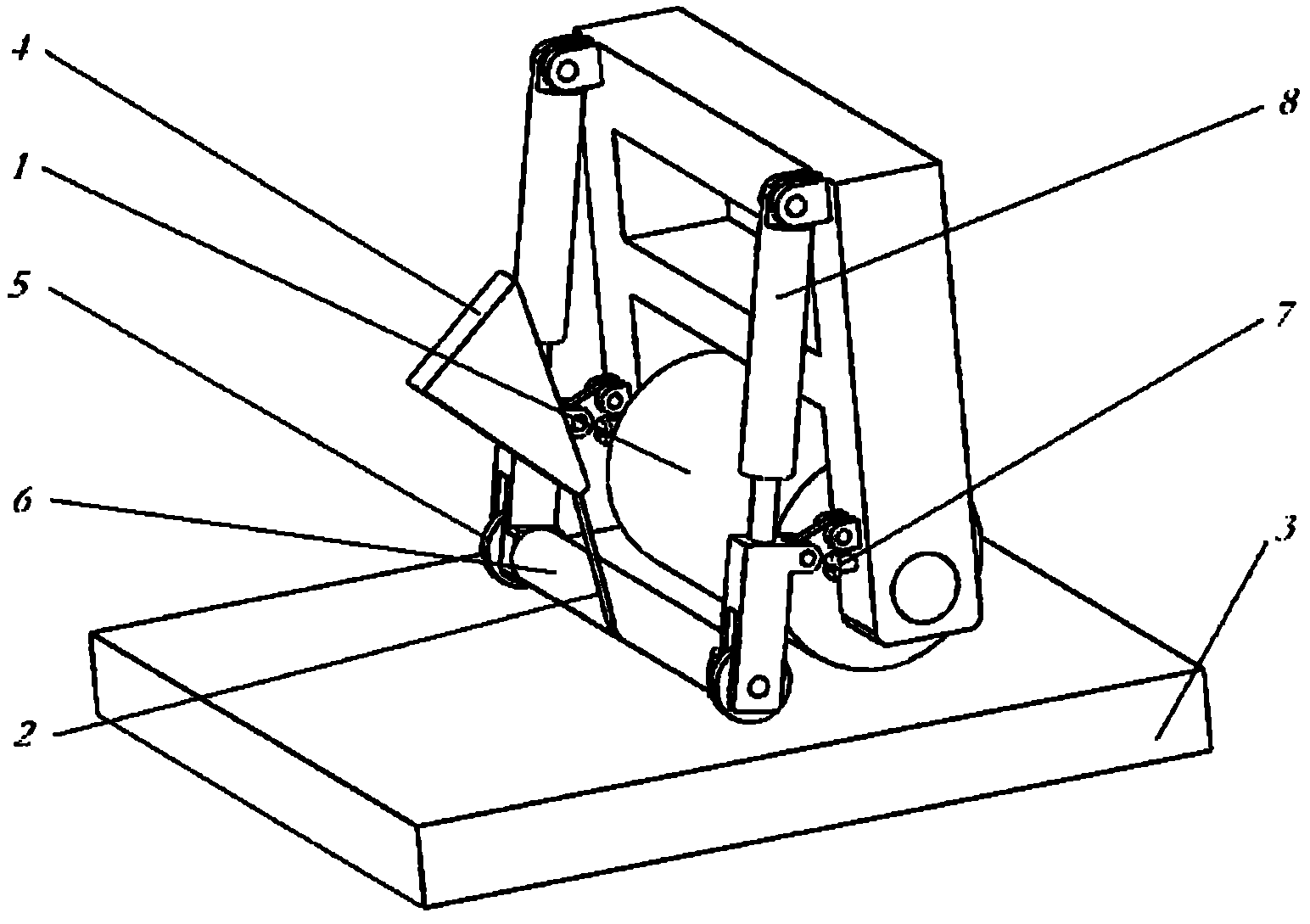

[0021] as attached figure 2 , shown in 3, this mechanism mainly comprises: guide wheel (6), roller (5), flexible pressure roller (1), limit screw (7) and driving element are cylinder (8); This mechanism will guide wheel (6 ) is installed on the support of the flexible pressure roller (1) through a four-bar linkage mechanism, during the process of laying the fiber prepreg tape (2) on the surface of the mandrel (3), after the flexible pressure roller (1) is pressed down, The guide wheel (6) is driven down by the cylinder (8) or other forms of driving mechanism, contacts with the fiber prepreg (2), and works with the flexible pressure roller (1), so that the fiber prepreg (2) is on the flexible pressure roller (1) The angle between the mandrel (3) and the mandrel (3) is reduced before rolling, thereby reducing the wrapping angle between the fiber prepreg tape (2) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com