Method for making proanthocyanidin-rich wine and product thereof

A technology for proanthocyanidins and wine, which is applied in the preparation of wine, biochemical equipment and methods, preparation of alcoholic beverages, etc., can solve the problems of increasing the cost of wine, hidden safety hazards, increasing the content of proanthocyanidins in wine, etc. Guaranteed taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

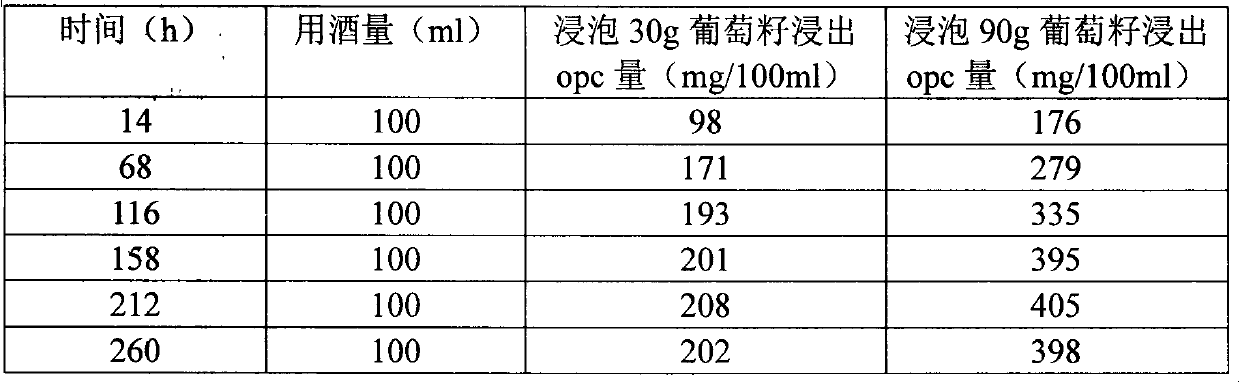

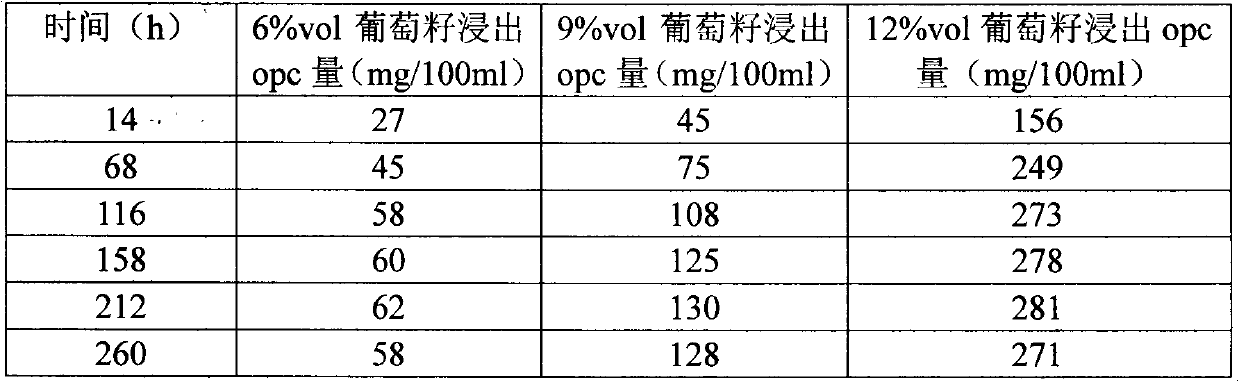

[0021] Example 1: Take 5 tons of Cabernet Sauvignon grape raw materials, crush them, put them into tanks, ferment, separate the pomace and fermentation liquid, age the fermentation liquid to obtain wine liquor, clean the grape seeds obtained by separating the pomace, and add 6 °Continue soaking in the above fermented liquid to obtain proanthocyanidin-rich wine liquid with proanthocyanidin content reaching 200mg / 100ml; use this wine liquid to blend ordinary brewed wine liquid to obtain proanthocyanidin-rich wine with proanthocyanidin content reaching 200mg / 100ml , Filling to get the finished product. The weight-to-volume ratio of the grape seeds to the fermentation broth is 1:3; the separation of the pomace comprises the following steps: separating the pomace from the fermentation broth, drying, blowing out the grape skins, rinsing the grape seeds with clean water, drying, Sterilize the grape seeds for later use. The time for adding the above-mentioned fermented liquid at 6°C ...

example 2

[0022] Example 2: Take 5 tons of Cabernet Sauvignon grape raw materials, crush them, put them into tanks, ferment, separate the pomace and fermentation liquid, age the fermentation liquid to obtain wine liquor, clean the grape seeds obtained by separating the pomace, and add 12 The wine obtained by the above-mentioned aging of ° continues to soak for 5 days (120 hours), and obtains the wine liquid of the concentrated proanthocyanidin in which the content of proanthocyanidin reaches 510mg / 100ml; The wine liquid is blended with the wine liquid) to obtain proanthocyanidin-rich wine in which the content of proanthocyanidin reaches 400mg / 100ml, and the finished product is obtained by filling. The weight ratio of the grape seeds to the fermentation broth is 1:1; the separation of the pomace comprises the following steps: separating the pomace from the fermentation broth, drying, blowing out the grape skins, rinsing the grape seeds with clean water, drying, and Grape seeds are steril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com