Grout-to-extinguish method of dual hard close-distance multiple seam gob areas

A goaf and short-distance technology, applied in mining equipment, earthwork drilling, fire prevention, etc., can solve problems such as long grouting time, astonishing waste of grout materials, and impact on coal mine safety production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

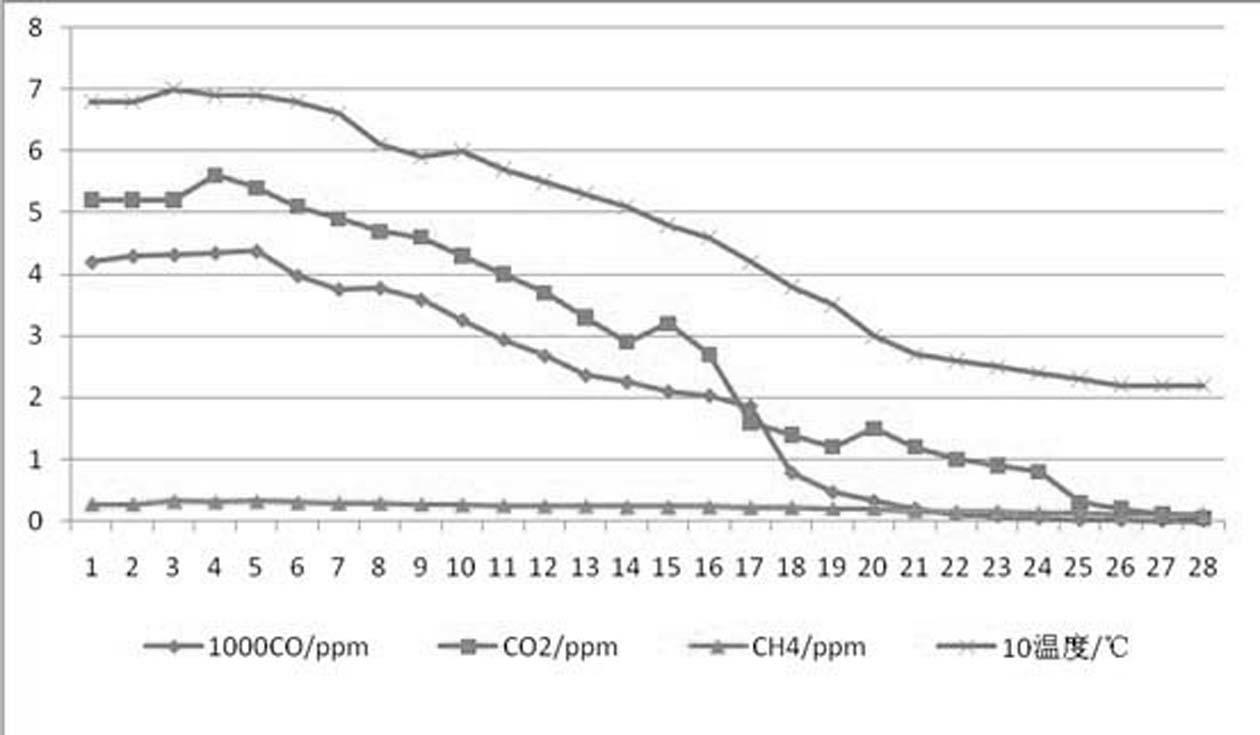

Examples

Embodiment Construction

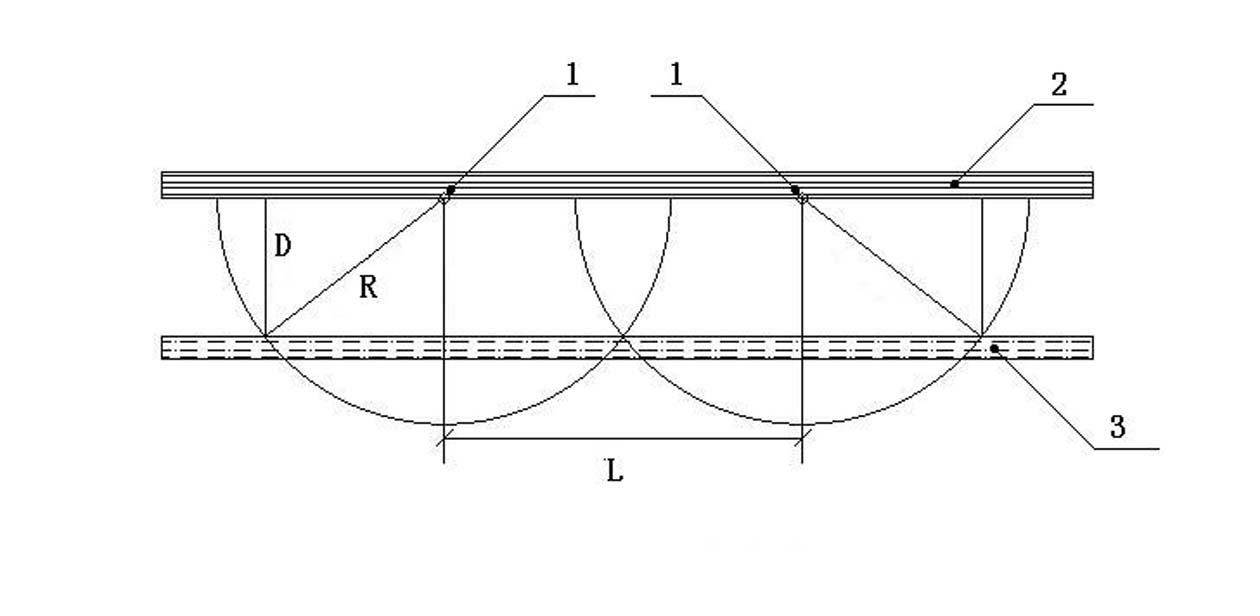

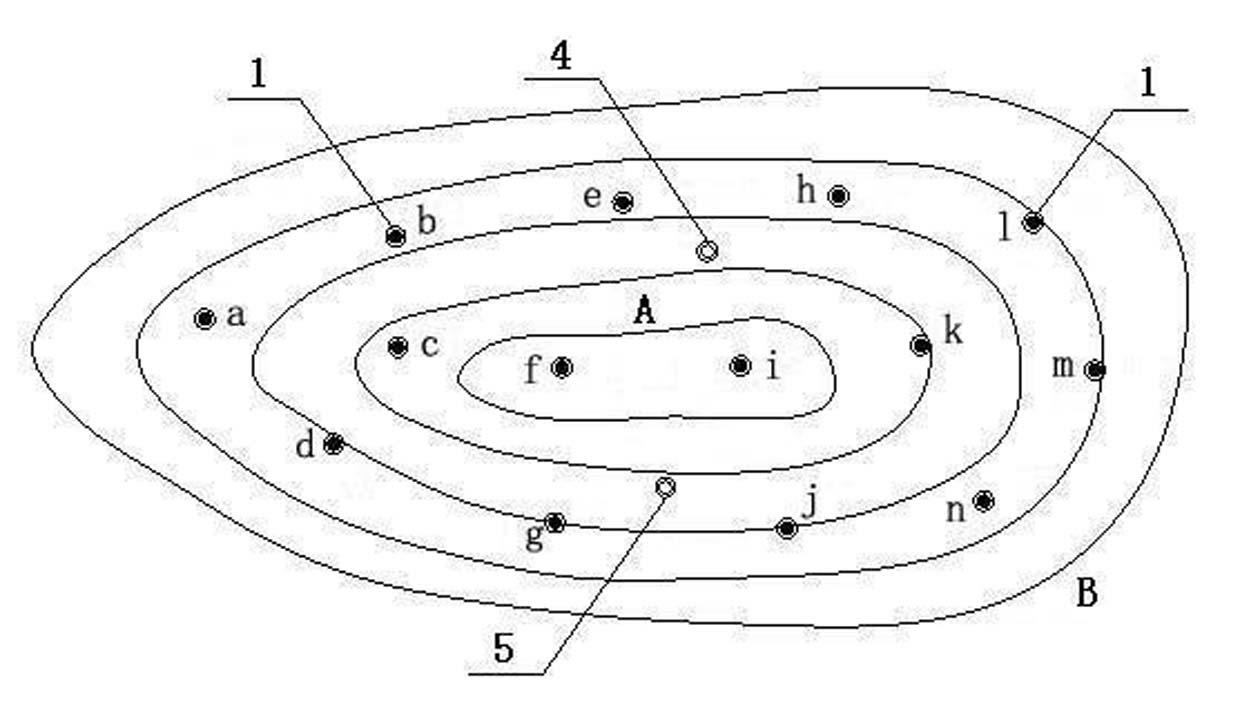

[0062] A grouting fire extinguishing method for a goaf with two hard and short-distance multi-coal seams, comprising the following steps: 1), when it is detected that spontaneous combustion occurs, immediately determine the specific location and range of spontaneous combustion; 2), determine the spontaneous combustion of the goaf After the location and scope of the fire area, the drilling and grouting shall be carried out from the ground of the fire area, and the sequence of drilling and grouting shall be from the boundary of the fire area to the center of the fire area;

[0063] Borehole grouting adopts the following steps: 1), determine the spacing of boreholes: first determine the diffusion radius of the grout in the goaf: In the formula: R-slurry diffusion radius, m; ξ-adjustment coefficient, take 0.5; T-grouting time, take 36000s; P c -Pressure in the grouting hole, Pa, can be measured by instruments or by p c = ρgh is calculated, where ρ is density of grout, g is gravi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com