Centripetal joint bearing with dual-half-outer-ring structure and assembling method thereof

A kind of joint bearing and half outer ring technology, which is applied in bearing components, shafts and bearings, sliding contact bearings, etc., can solve the problems of uneven force, increase bearing installation space, and do not need large-scale structures, and achieves expansion of application fields and range, solving process difficulties, and improving the effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

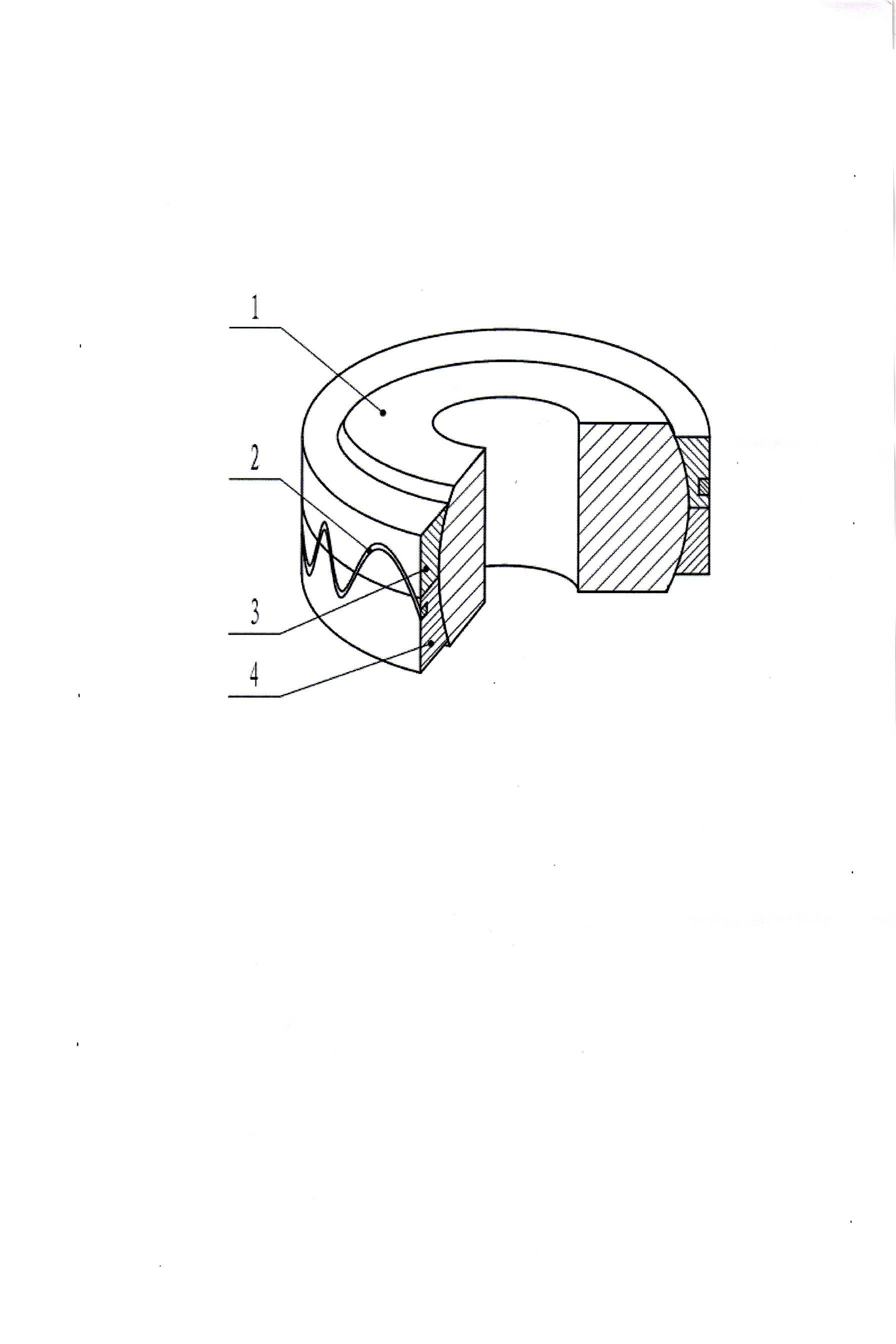

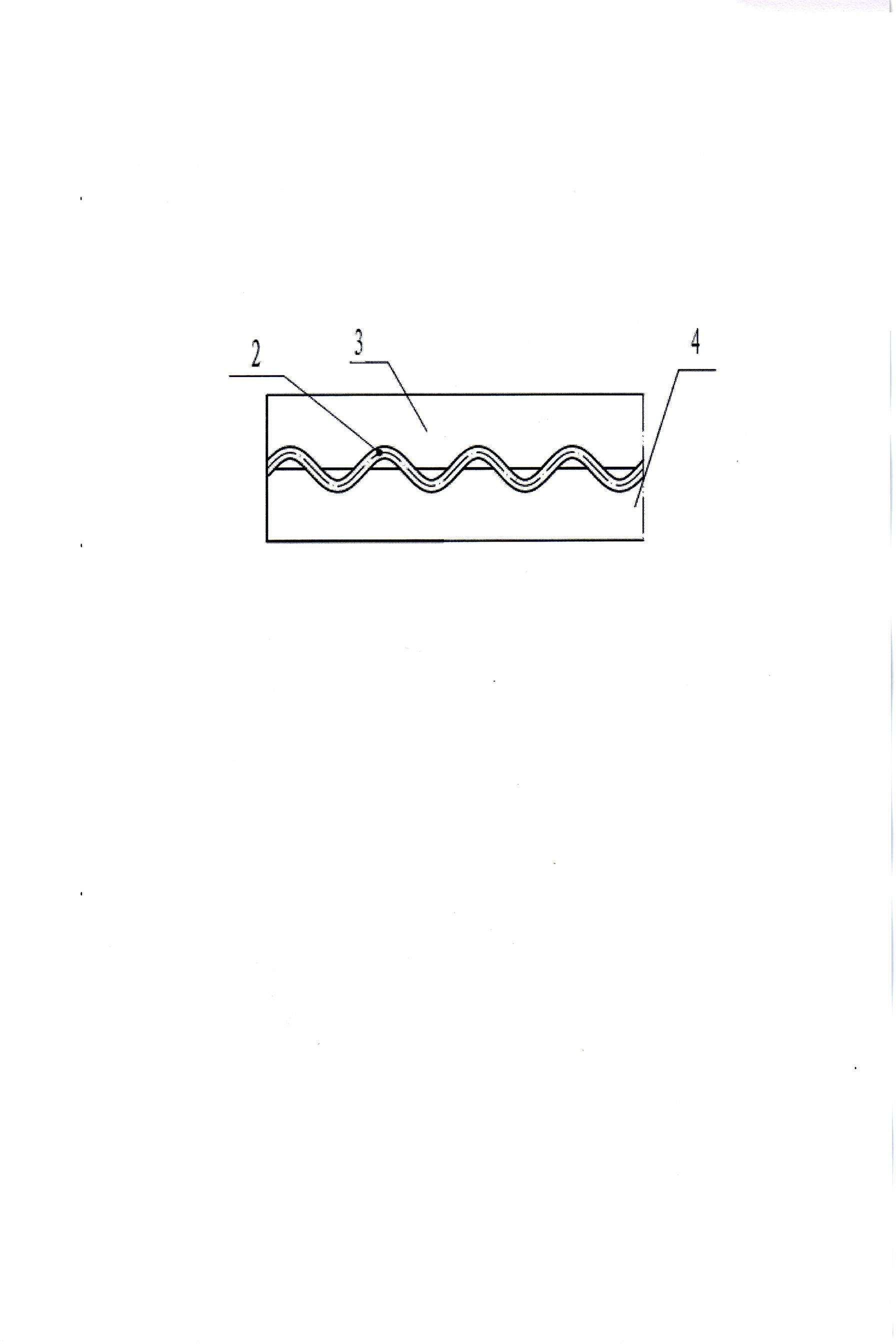

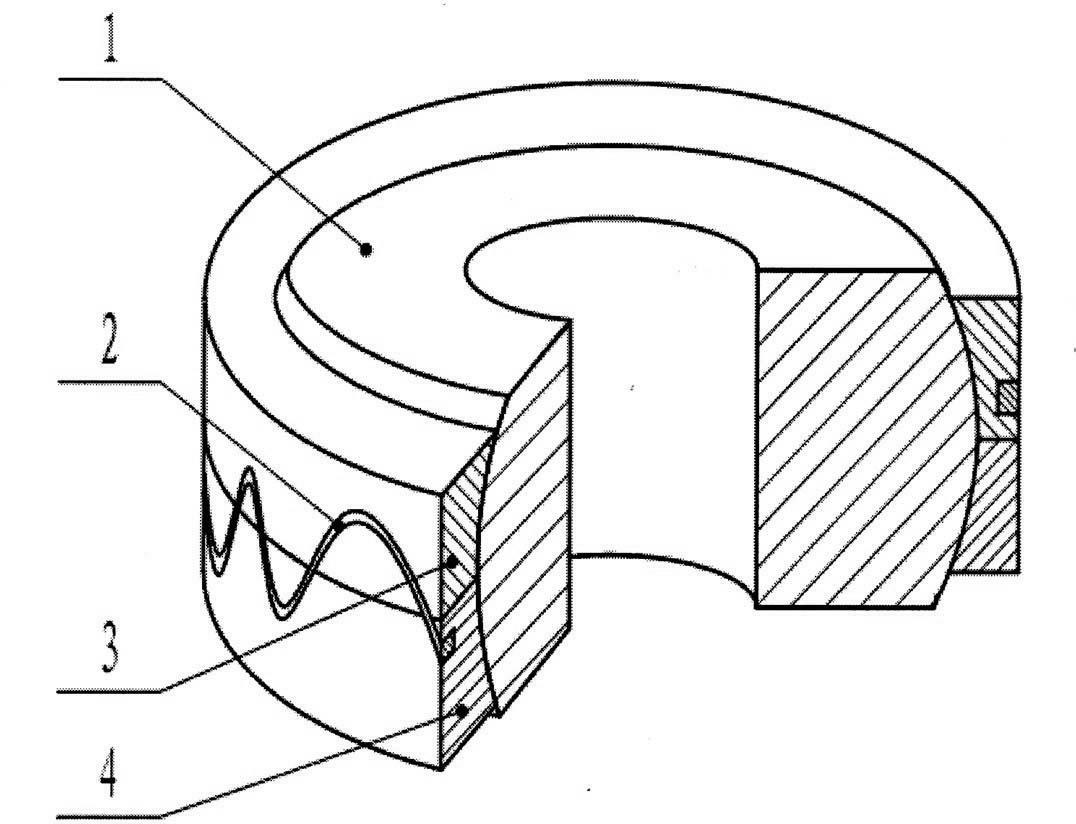

[0012] exist figure 1 and figure 2 In the radial spherical plain bearing with a double-half outer ring structure shown, the bearing inner ring 1 of the radial spherical plain bearing is placed between the left half outer ring 3 of the bearing and the right half outer ring 4 of the bearing, and the left half outer ring of the bearing is connected to the right half of the bearing. There are matching grooves at the smaller cross section of the half outer ring for alignment assembly, and there are continuous wave grooves on the outer surface of the outer surface where the left half outer ring of the bearing and the right half outer ring of the bearing are assembled together. The groove is processed by numerical control at one time, and the center line of the wave-shaped groove is a sinusoidal line of at least four periods on the entire circumferential surface. Align the left half outer ring of the bearing with protrusions and grooves and th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap